Franklin Fueling Systems TS 550 evo Fuel Management System Operators Guide User Manual

Page 21

17

Statistical Continuous Automatic Leak

Detection (SCALD)

SCALD (Statistical Continuous Automatic Leak Detection)

runs 24hrs a day performing 0.2 GPH tests on tanks at

sites that do not have enough quiet time to complete static

tests (some static tests may take up to eight hours to

complete).

SCALD Testing is available only if the option for Tank

Testing is enabled. This option can be ordered when

initially purchasing the console or afterwards. The part

number for this option is TS-TT for the TS-550 evo.

Why Continuously Test Tank Integrity

In compliance with federal, state and local regulatory

policies, all tanks must be monitored for leaks due to

environmental and public safety/health concerns. Tank

Integrity Tests determine whether there is a leak.

Since SCALD continuously runs statistical tank leak tests

during the inactive periods between product deliveries and

dispensing, it is particularly useful for:

• Operations that are open for business on a continuous

(24 hours, 7 days a week) schedule

• Operations that are open for business on a two-shift

schedule and where deliveries may occur at any time

during non-business hours (normally schedule tank leak

tests may require up to 8 hours of inactivity).

Terms

Qualify – The percentage of product that the tank is

required to contain prior to testing according to the

programmed “Qualify” parameter.

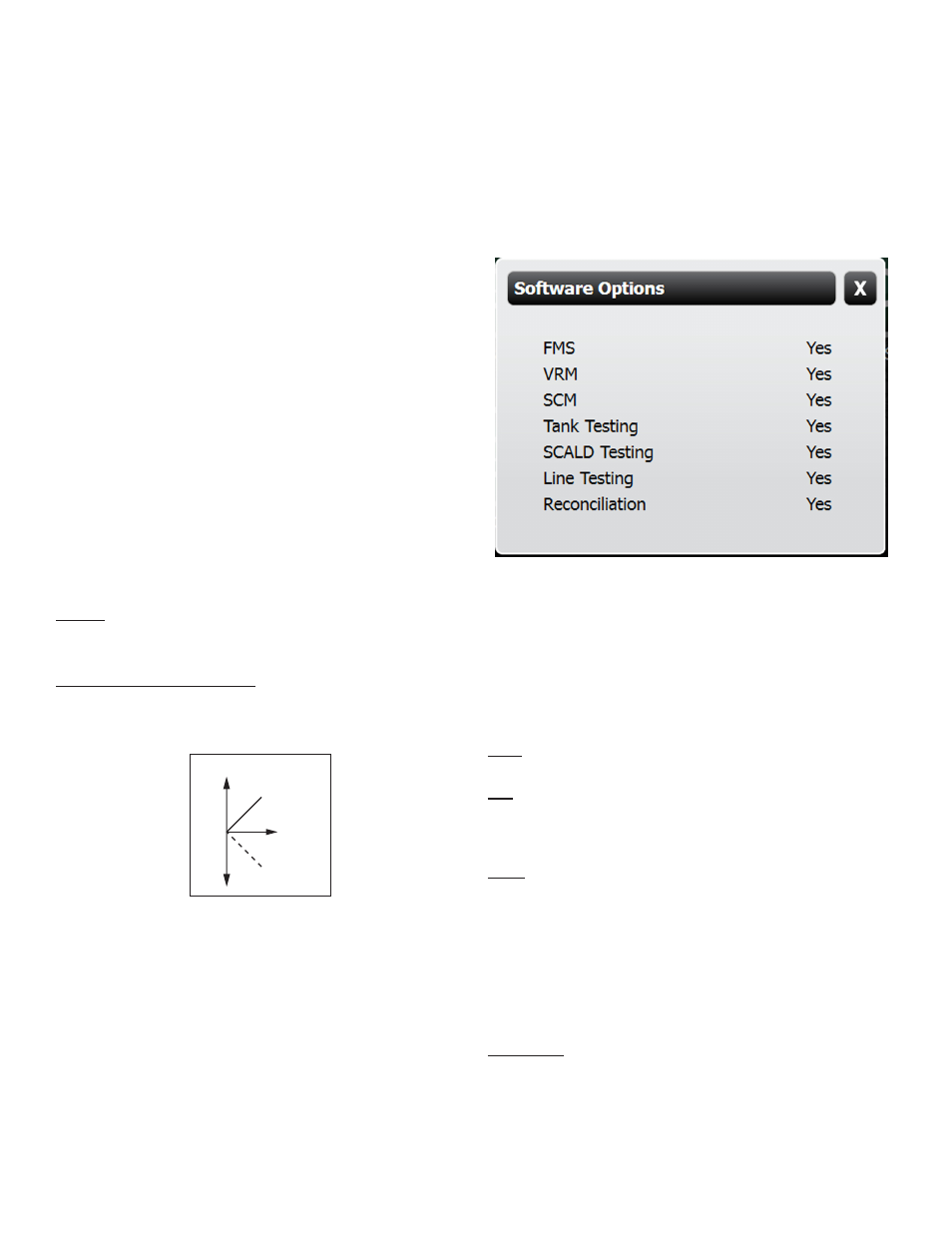

Slope (Tank Testing Reports) – A ratio of the calculated

rate of change to the time the rate is measured. Slope

is affected by leaks and by many other sources of

interference.

Flow

Time

No Leak

(+) slope

(–) slope

A negative slope or decrease indicates loss of product

volume. A positive slope or increase indicates a rise in

product volume.

SCALD Testing Requirements

To perform SCALD testing, the SCALD software must be

enabled. To verify that the software is enabled:

1. Starting at the Home screen, open the Quick Jump

Menu.

2. Select Utilities from the QJM then select System.

3. Press the Software Options Button.

4. Under Software Options, Tank Testing will appear.

A “yes” in the Enabled column indicates that the

software has been purchased and is enabled.

When SCALD Tests

SCALD works by collecting quiet intervals in-between

dispensing. A “QI” is obtained when a thermally stable tank

is idle for 20 minutes with no dispensing, no deliveries

and no other movement of the probe floats. Once four QIs

are collected, the console will analyze the data and either

Pass, Fail, Incomplete, or Abort that test. The four QIs can

be collected over a period of several days or weeks.

SCALD Results

Pass – A passing result ensures the integrity of the tank is

good.

Fail – Test failure will be indicated by a Warning light and/or

annunciator. Additionally, a report may print (if the console

is programmed to do so, see the TS-550 evo Programming

Guide p/n 000-2173).

Abort – The result is due to variations in float level and/

or product temperature that are outside the leak test

threshold. This may be caused by:

• Dispensing

• Rapid Temperature Change

• Delivery

• Product Lower than the

lowest RTD (Resistance

Temperature Detector)

• Theft

• Pump Started

• Loss of Probe Signal

Incomplete – When the test does not collect enough data

before the programmed time limit, the test is Incomplete.

When it is necessary to obtain valid results for compliance

reasons, start the test manually.