Wire sensor alarms – Franklin Fueling Systems TS 550 evo Fuel Management System Operators Guide User Manual

Page 37

33

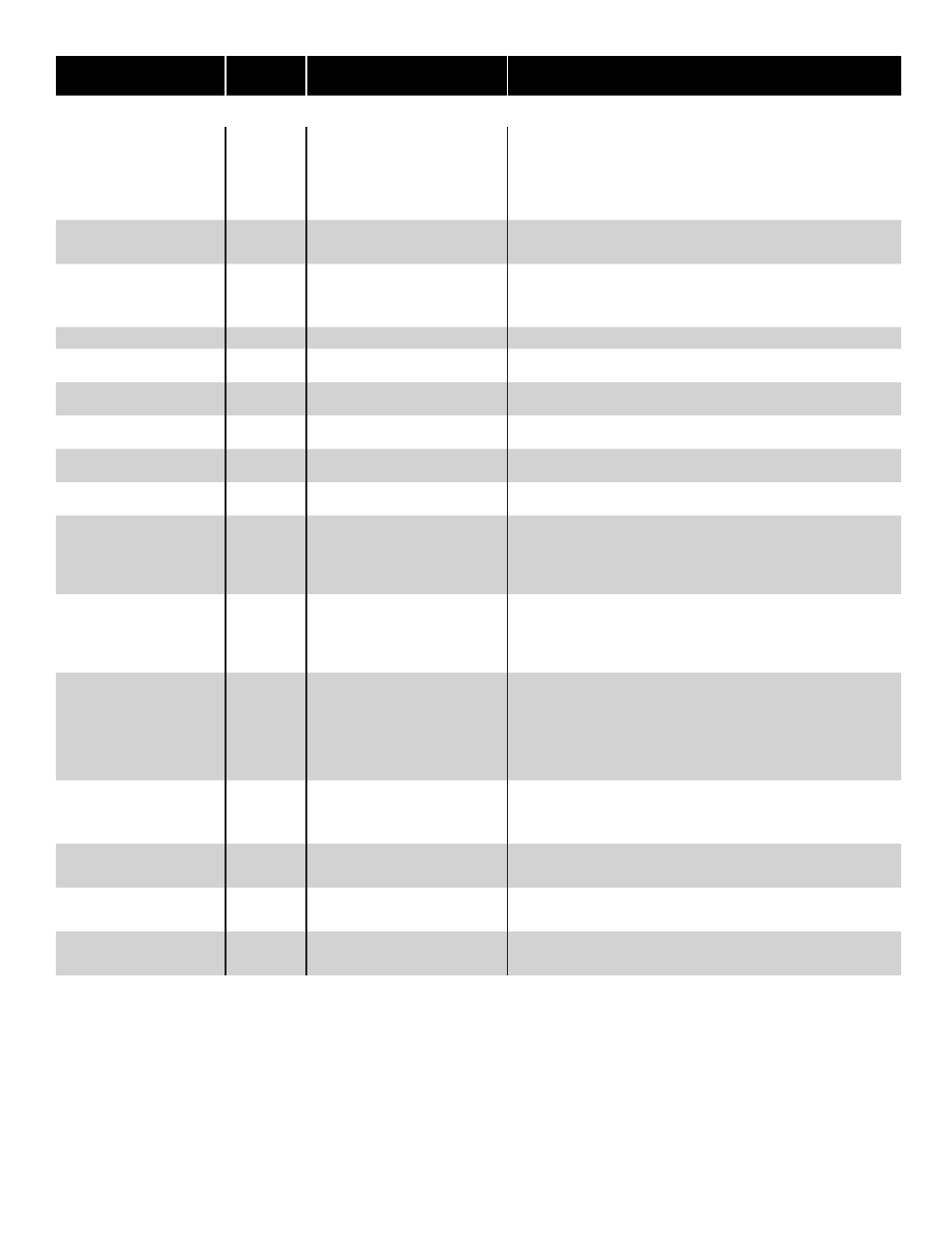

Displayed Alarm /

Warning

Device

Description

Recommended Actions

Wire Sensor Alarms

SN2 Sensor On

ChannelSN2 Sensor shows alarm status.

Inspect location for presence of liquid. In the case of a leak, follow

site policy procedures. If no liquid is present, and alarm still exists,

sensor may be tripped on error. Check wiring continuity from sensor

to console. Test sensor at console, trip sensor on purpose. Verify

console terminal wiring. If issue still exists, inspect wiring to sensor.

Contact Franklin Fueling Systems’ Technical Services for support.

SN2 Fuse Blown

ChannelSN2 2-Wire Sensor Module fuse blown

due to unknown causes.

The fuses on the Sensor boards are non-serviceable per UL listing

standards. The module must be replaced if the fuse is blown.

SN3 Data Error

ChannelSN3 Console has received erroneous

data from sensor.

Check wiring continuity from sensor to console. Test sensor at

console, trip sensor on purpose. Verify console terminal wiring. If

issue still exists, inspect wiring to sensor. If the condition still exists,

contact Franklin Fueling Systems’ Technical Services for support.

SN3 Dry Well

ChannelSN3 Monitoring well is dry.

Visually verify that the alarm is correct.

SN3 Fuse Blown

ChannelSN3 3-Wire Sensor Module fuse blown

due to unknown causes.

The fuses on the Sensor boards are non-serviceable per UL listing

standards. The module must be replaced if the fuse is blown.

SN3 High Brine

ChannelSN3 Brine solution has tripped high

level brine sensor.

Verify actual level of solution and sensor installed location.

SN3 Low Brine

ChannelSN3 Brine solution has tripped low level

brine sensor.

Verify brine level and sensor location.

SN3 ID Error

ChannelSN3 Discriminating sensor is given an

improper ID.

Verify sensor programming and Auto configuration.

SN3 No Signal

ChannelSN3 Console is not receiving data from

a discriminating sensor.

Verify programming of sensor type and wiring connection.

SN3 Product

ChannelSN3 Discriminating sensor has

detected product present at

location.

Visually inspect location carefully for presence of liquid. In the case of

a leak, follow site policy procedures. If no liquid is present, and alarm

still exists, sensor may be tripped on error. Check wiring continuity

from sensor to console.

SN3 Pwr Short

Slot

3-Wire sensor malfunction.

If a 2-Wire sensor is used on a 3-wire module ensure that the

red / pwr terminal is not used. If a 3-wire sensor is used, disconnect

wires and see if alarm clears. If alarm clears inspect shorts in wiring.

If alarm stays at PWR short replace module. Contact Franklin Fueling

Systems’ Technical Services Dept. for support.

SN3 Sensor On

ChannelSN3 Discriminating sensor shows

alarm status.

Inspect location for presence of liquid. In the case of a leak, follow

site policy procedures. If no liquid is present, and alarm still exists,

sensor may be tripped on error. Check wiring continuity from sensor

to console. Test sensor at console, trip sensor on purpose. Verify

console terminal wiring. If issue still exists, inspect wiring to probe. If

the condition still exists, contact Franklin Fueling Systems’ Technical

Services for support.

SN3 Sump Full

ChannelSN3 3-wire sensor detected sump full

of liquid.

Inspect location for presence of liquid. In the case of a leak, follow

site policy procedures. If in alarm with no liquid is present, sensor

may be tripped on error. Check wiring continuity from sensor to

console.

SN3 Sync Error

ChannelSN3 3-wire sensor data signals not in

sync with module.

Verify correct wiring and re-make the connections. Verify sensor type.

SN3 Vapor

ChannelSN3 3-wire discriminate sensor

detecting vapors at location.

Visually inspect area for product presence. Verify the vapor level has

been calibrated correctly.

SN3 Water

ChannelSN3 3-wire discriminate sensor

detecting water at location.

Visually inspect area for water presence.