GE Industrial Solutions 6KCV300WPD User Manual

Page 71

Control

Description

0

1

otherwise

Functionalities are all enabled: diameter and thickness are estimated from line speed

and winder motor speed (WMotSpd)

Diameter and thickness estimation are disabled, but diameter is updated according to

actual thickness. This is used during speed match and when torret is rotating. In this

case material path is changing so diameter estimation has to be disabled, however

, diameter is increasing (or decreasing if unwind) of

thickness.

If thickness estimation is disabled (when

or Tau2 are set to

see

below) and thickness is zero (when

is set to 0) this case is

cal to

Functionalities are all disabled: estimated diameter and thickness are constant.

This case is identical to Control=1 when thickness estimation is disabled (when Taul

or Tau2 are set to

see below) and thickness is zero (when

is set to 0).

Unwind input indicates direction of winding: rewinder and diameter increase when unwind = 0, unwinder

and diameter decrease when unwind = 1.

Diamobs block can control increment or decrement of diameter according to direction of winding: rewinding

or unwinding. For this

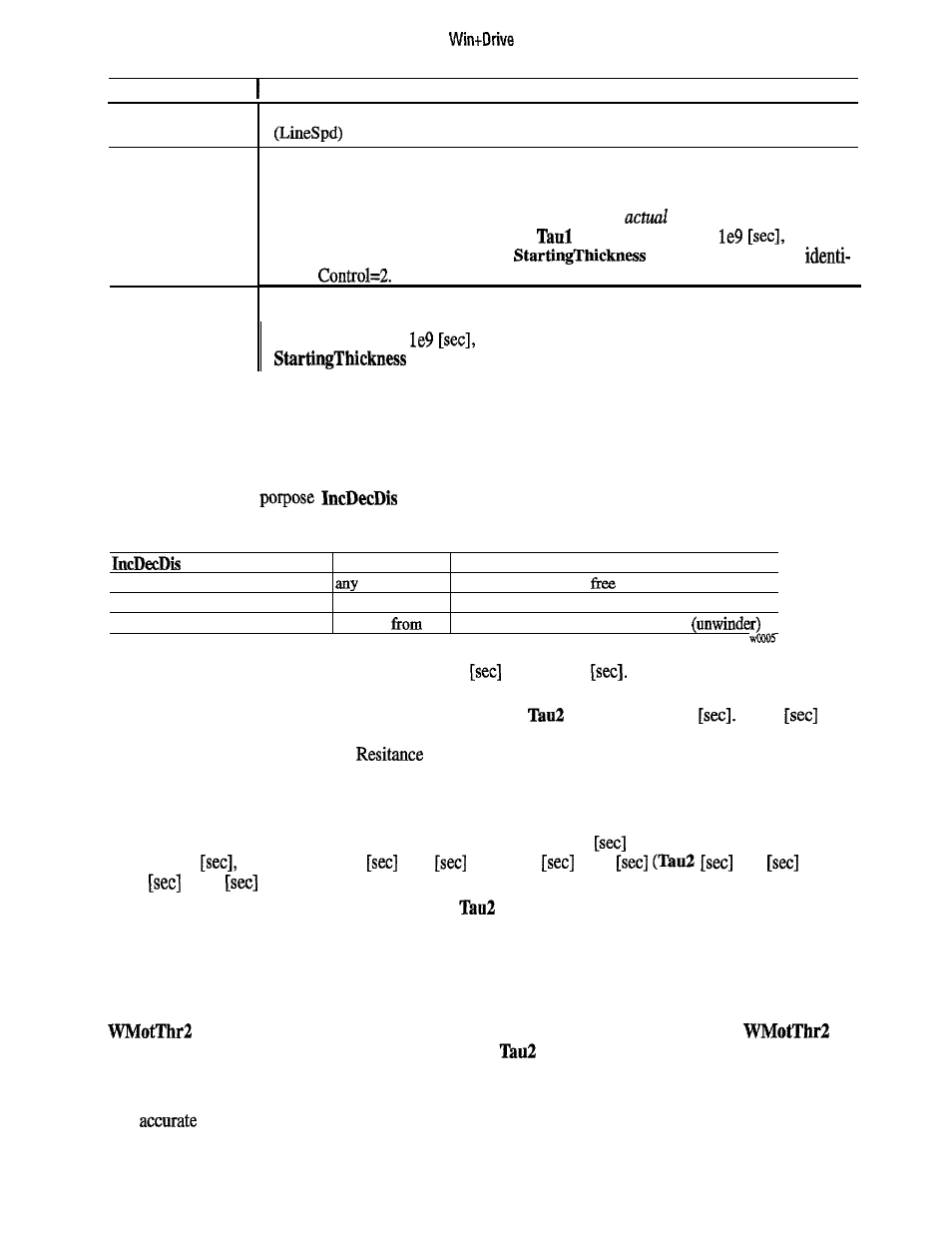

(Increment and Decrement Disabling) and Unwind (Unwinder)

inputs are provided. The meanings of these inputs are described in the following table:

0

Unwind

Description

Estimated

diameter is

different from 0

different from 0

0

Estimated diameter can only increase (rewinder)

different

0

Estimated diameter can only decrease

Diamobs is a algorithm with two time constants: Taul

and Tau2

These inputs determine time that

observer takes to estimate diameter and thickness.

The simplest case is when user needs to estimate only diameter:

must be set to le9

Taul

is

diameter estimation time constant. It represents the same concept of time constant in electronic analog circuits

and it is equivalent to the product of

and Capacitance. It is the time that estimated value takes to

reach 63% of its steady state value. After four times time constant reaches steady state value (98%).

More complex case is when user needs to estimate both variables: diameter and thickness. This is the case

when material is very thick.

If for example user wants to estimate diameter with a time constant of 2

and thickness with a time

constant of 10

he has to set Taul

to 2

and Tau2

to 10

to 2

and

Taul

to 10

is exactly equivalent).

In general terms the least value between Taul and

is the time constant of diameter estimation while the

largest value is the time constant of thickness estimation.

Diamobs can estimate diameter and thickness with accuracy depending on winder motor speed (WMotSpd):

the higer winder motor speed, the more accuracy estimation will be. When winder motor speed is close to

zero, estimations have to stop. For this purpose two winder motor speed thresholds are provided (WMotThrl

and WMotThr2). When WMotSpd is below WMotThrl estimation is disabled. When WMotSpd is above

estimation is completely enabled. When WMotSpd is between WMotThrl and

time constants start very high and decrease until Taul and

when WMotSpd reaches WMotThrl.

WMotThrl must be below WMotThr2.

WMotThrl and WMoThr2 values depends on speed sensor accuracy and on sample time of the control. The

less

sensor and the shorter sample time, the higher thresholds have to be.

6 1