Application, Technical data, 7application – M&C TechGroup SP2000-H320_S2 Operator's manual User Manual

Page 9: 8technical data, Is added to the flue gas in order to reduce the no, And so, Standard ** = option, Standard

9

Gas sampling and gas conditioning technology

2-1.1.4-ME

7

APPLICATION

The probes type SP2000-H320/S.. are used for continuous gas sampling in processes with high dust

load and high temperatures and/or high gas humidity where additionally solid particles may precipi-

tate.

M&C has developed these probes for eg. continuous gas sampling in waste gas of DENOX

plants (SCR) where NH

3

is added to the flue gas in order to reduce the NO

X

content. With tempera-

tures of <300 °C, ammonium salts are produced due to the chemical reaction of NH

3

and SO

2

/SO

3

in

the flue gas. This salification will choke in a very short time the filters and sample lines.

8

TECHNICAL DATA

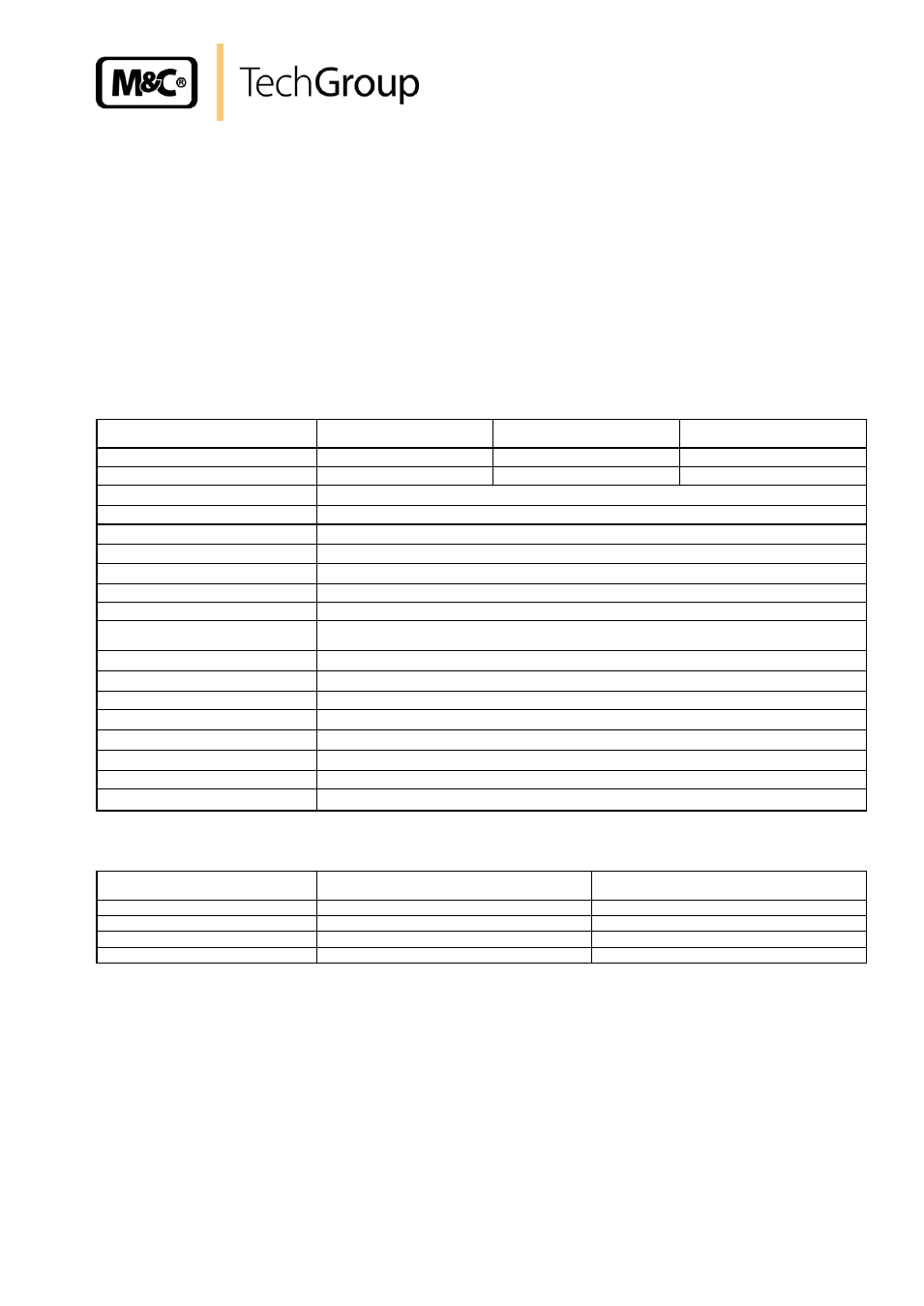

Gas sample probe Type

SP2000-H320/S

SP2000-H320/S1

SP2000-H320/S2

Part number

20S5000 (a)

20S5005 (a)

20S5010 (a)

Temperature regulation

Thermostat

FeCu-Ni (Regulator optionally)

FeCu-Ni (Regulator optionally)

Probe heating

max. 320 °C

Ambient temperature

+5 °C to +60 °C ** optionally with GFK protective housing -20 °C to +60 °C

Sealing material

Graphite

Material probe flange sealing

Novapress

Sampling tube/Pre filter

Optionally

Sampling pressure max.

0,4

–2 bar* abs.

Volume of filter chamber

120 cm

3

Porosity

S

– 2K150 = ceramic*, 2 micron, /F-0,1GF150 = Glass fibre** 0,1 micron

/F-3SS150** 3 micron, /FW = Glass fibre-filter cotton**

Ready for work

after 2h

Connection gas outlet

Threaded hose coupling DN 4/6

Connection test gas

Pipe connection Ø 6 mm with blind plug, optionally Ø ¼“ (a)

Power Supply

230V 50/60Hz, 800W, optionally 115V 60Hz (a)

Electrical connection

Terminals max. 2,5 mm

2

, terminal range 0,75

– 4mm

Standard of electrical equipment

EN 61010, EN 60519-1

Mounting flange

DN 65 PN 6, Form B, 1.4571*, > DN or ANSI possible**

Weight

17 kg

* = Standard ** = Option

Filter element Type

Filter porosity

Material

S-2K 150

2µm

Ceramic *

S-3SS 150

3µm

Stainl. Steel 1.4401

S-0,1GF 150

0,1µm

Glass fibre

FW

--------

Glass wadding

* = Standard