Film curl, Microfilm curl check – Kodak I7300 User Manual

Page 139

A-61133 March 2003

A-9

•

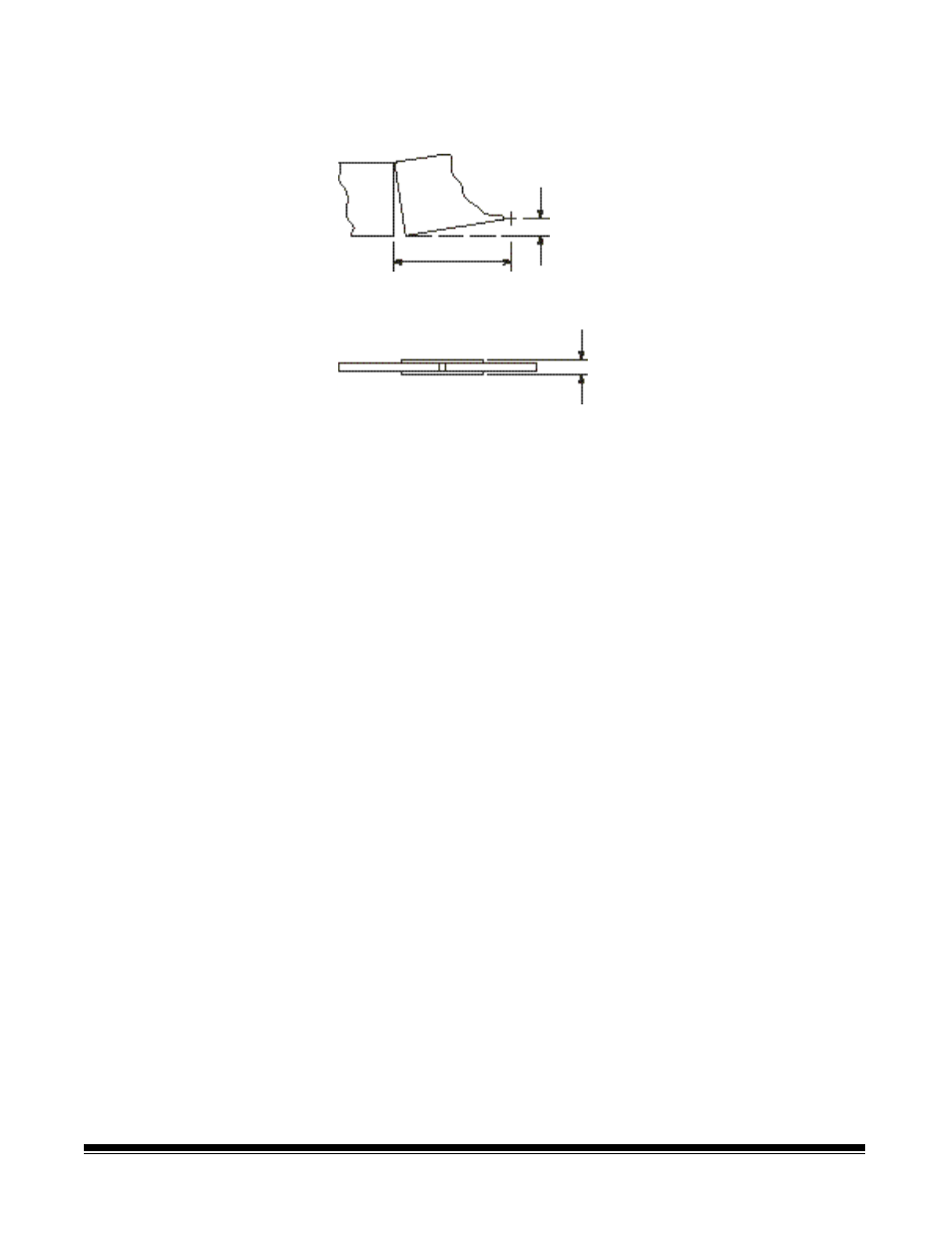

Make sure there is minimal skew (a slanted cut leaving an angled

gap) between the leader tape and film. The skew should be no more

than 0.002 in./in. (0.05 mm/mm).

•

The thickness of the connecting section should be no more than

0.014 (0.38 mm).

Film curl

For most film types and operating conditions, a certain amount of film

curl can exist without adversely affecting the performance of the

scanner (see the next section entitled, “Microfilm curl check”). Under

certain conditions, however, curled film ends may result in degraded

threading performance. Specific conditions that may result in degraded

performance with curled films include:

•

partial reels (reels containing less than a full amount of film)

•

operating environments with low relative humidity

•

enclosed ANSI magazines

In order to maintain reliable film threading under these conditions or

others where curled films may cause degraded performance, certain

steps can be taken:

•

Straighten the film end (leader) by forcing it over a straight edge or

surface to remove the curl and/or twist from the first 6 to 8 inches.

(150 to 200 mm). Care must be taken not to crease or damage the

film end during straightening.

•

Attach a straight film leader in good condition that is approximately

36 in. (915 mm) long. (A leader of 5-mil thick polyester film will obtain

the best results.)

Microfilm curl check

The microfilm can have a certain amount of curl without affecting

operation. To check the curl of your microfilm:

1. Place the diagram upright with the outline of the reel at the top of the

page.

2. Place your reel over the outline and let the film hang down.

3. Move your reel until the film’s curl matches one of the arcs in the

diagram.

The film curl is acceptable if it falls within the shaded area (see the next

page).

Skew

0.002 in./in.

(0.05 mm/mm)

or less

Thickness

0.014 in.

(0.38 mm)

or less