Kohler Command Pro CV980 User Manual

Page 103

Section 9

Inspection and Reconditioning

9

9.11

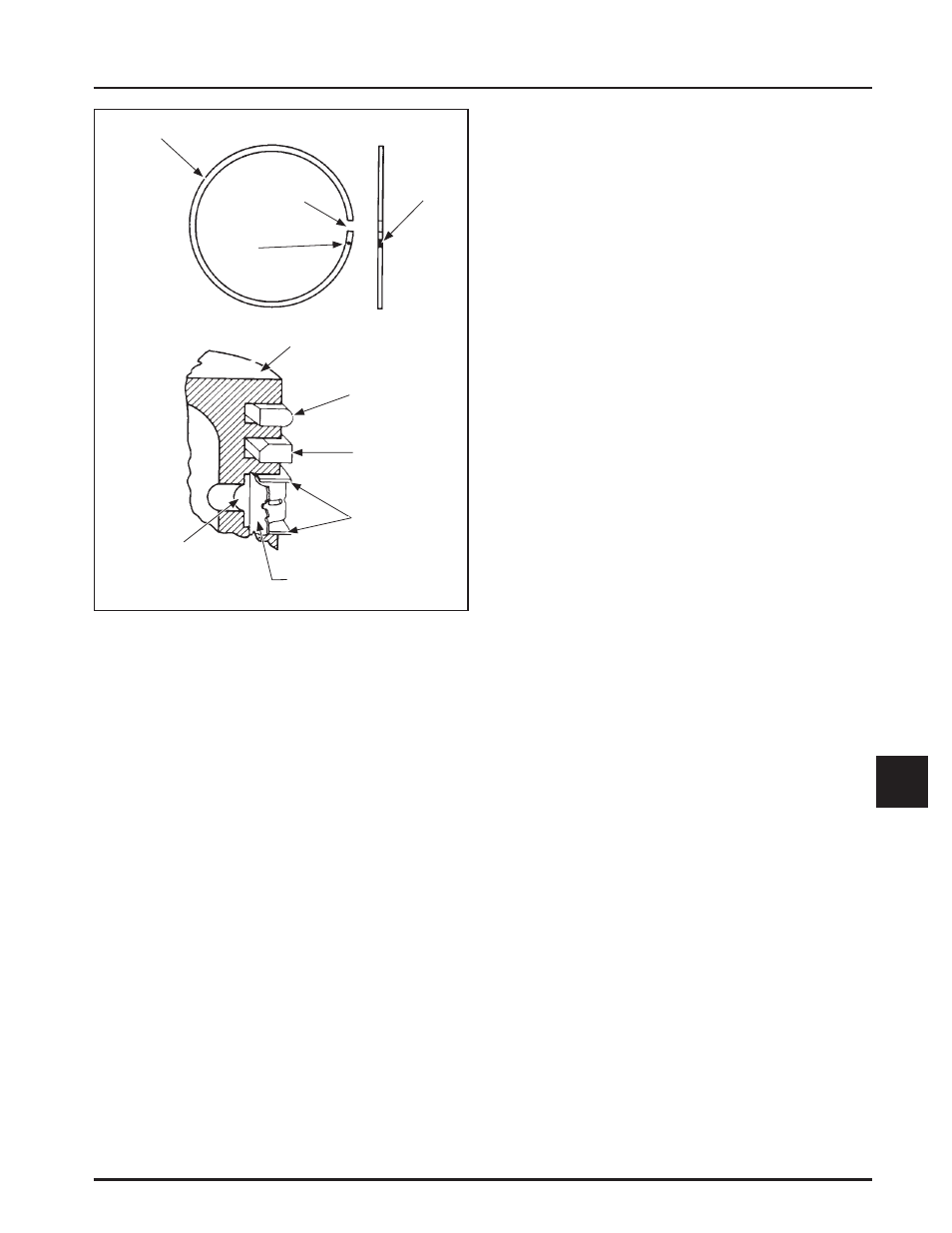

Figure 9-12. Piston Ring Installation.

ȱ ŗǯȱ ȱȱȱǻĴȱ ǼDZȱȱȱ

expander and then the rails. Make sure the ends

of the expander are not overlapped.

2. Middle Compression Ring (Center Groove):

Install the center ring using a piston ring

ȱǯȱȱȱȱȃęȄȱ

mark is up or the dykem stripe (if contained) is to

ȱĞȱȱȱȱǯ

3. Top Compression Ring (Top Groove): Install the

top ring using a piston ring expander. Make sure

ȱȃęȄȱȱȱȱȱȱ¢ȱ

ȱǻȱǼǰȱȱȱȱĞȱȱȱȱǯ

Connecting Rods

ěǰȱȬȱȱȱȱȱȱȱ

engines.

Inspection and Service

Check the bearing area (big end) for excessive wear,

score marks, running and side clearances (refer to

ȱŗǰȱȃęǰȱǰȱȱȱ

ȱȄǼǯȱȱȱȱȱȱȱȱȱ

excessively worn.

Service replacement connecting rods are available in

STD crankpin size and 0.25 mm (0.010 in.) undersize.

Always refer to the appropriate parts information to

ensure that correct replacements are used.

Hydraulic Lifters

Inspection

ȱȱȱȱȱȱ¢ȱĞȱȱ ȱ

ȱǯȱȱȱĞȱȱȱȱǰȱ¢ȱȱ

ȱȱȱ

ȱȱ25 357 14-S to the

ȱȱȱ ȱĞȱȱȱȱǯ

“Bleeding” the Lifters

To prevent a possible bent push rod or broken rocker

ǰȱȱȱȱȱȃȄȱ¢ȱ¡ȱȱȱȱȱ

Ğȱȱ¢ȱȱǯ

1. Cut a 50-75 mm (2-3 in.) piece from the end of an

old push rod and chuck it in a drill press.

2. Lay a rag or shop towel on the table of the drill

ȱȱȱȱĞǰȱȱȱǰȱȱȱ

towel.

3. Lower the chucked push rod until it contacts the

ȱȱȱĞǯȱ ¢ȱȃȄȱȱȱ

two or three times to force the oil out of the feed

ȱȱȱȱȱȱĞǯ

Governor Gear Assembly

Inspection

The governor gear is located within the crankcase.

Inspect the governor gear teeth. Replace the gear if it

is worn, chipped, or if any teeth are missing. Inspect

the governor weights. They should move freely in the

governor gear.

Disassembly

The governor gear must be replaced once it is

removed from the crankcase.

DZȱ ȱȱȱȱȱȱȱĞȱ¢ȱ

small molded tabs in the gear. When the

ȱȱȱȱȱĞȱȱȱȱ

destroyed and the gear must be replaced.

Therefore, remove the gear only if absolutely

necessary.

Piston Ring

End Gap

,GHQWL¿FDWLRQ

Mark

Piston

Top

Compression

Ring

Center

Compression

Ring

Rails

Expander

Oil Control Ring

(Three-piece)

Dykem

Stripe