Carrier 38AH044-134 User Manual

Page 50

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

9. Units 38AH094, 104:

a. Remove 4 large screws securing compressor to the com

pressor rails.

b. Lift compressor off mounting bolts and remove.

Compressor Replacement — Perform the following:

1. Reverse procedure in Compressor Removal section to end

of Step 4.

2. Reinstall service valves and safety switches, and tighten

to torques as listed:

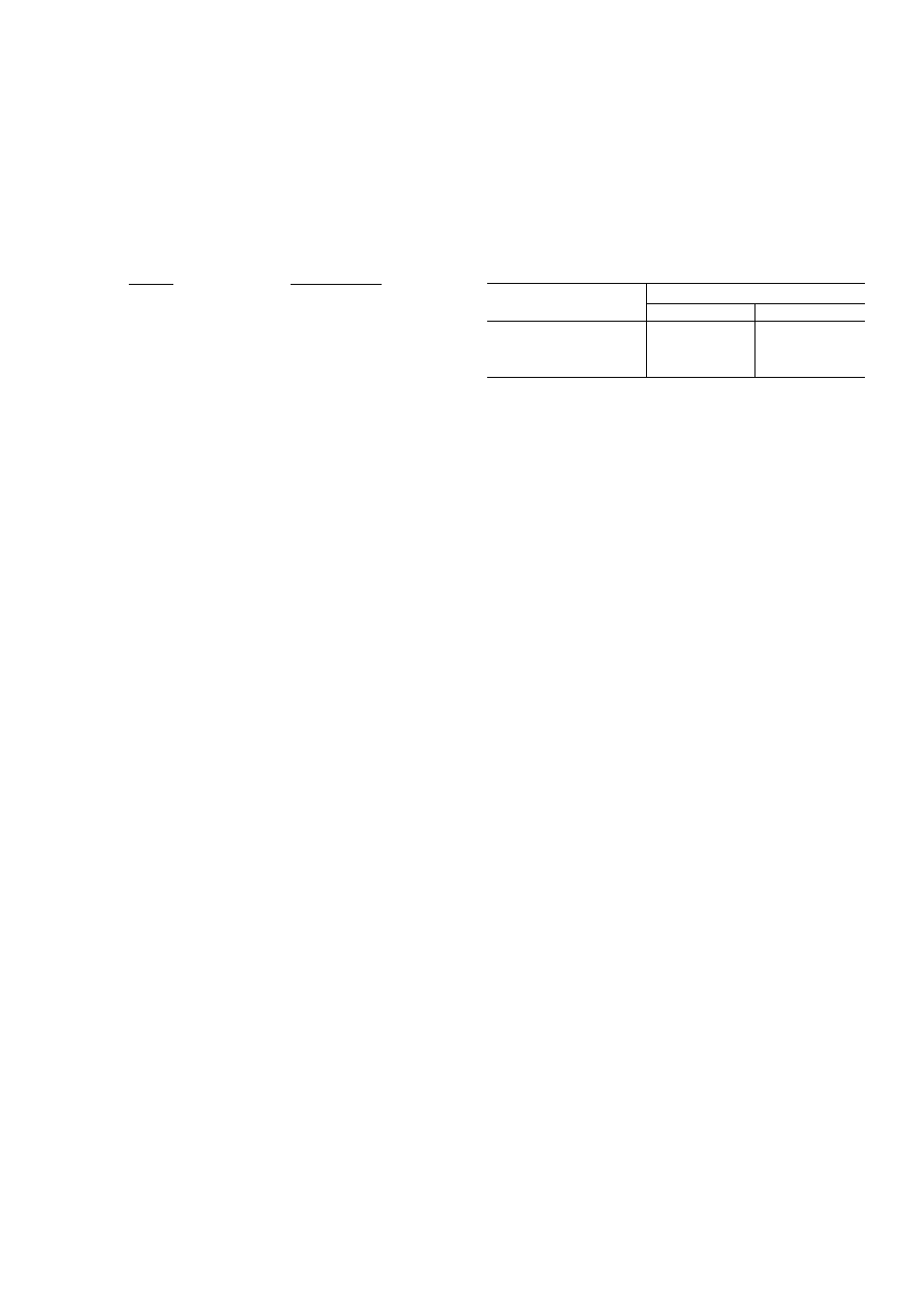

Torque

Tighten discharge valves to —

20-25 ft-lbs ( 27- 34 N-m)

80-90 ft-lbs (109-122 N-m)

Tighten suction valves to —

80- 90 ft-lbs (109-122 N-m)

90-120 ft-lbs (122-163 N-m)

Tighten the following fittings as specified —

60 ft-lbs (81 N-m)

Discharge Gas Thermostat

120 in.-lbs (13.5 N-m) High-Pressure Switch, Fan-

Cycling Pressure Switch

120 in.-lbs (13.5 N-m) Low-Pressure Switch

3. Leak-check and evacuate system, reclaim refrigerant.

4. Recharge system per pre-start-up and start-up sequences.

Recheck oil levels.

5. Energize crankcase heater for 24 hours prior to restart of

system.

Compressor(s)

06E-250

06E-265,275,299

06E-250

06E-265,275,299

OIL CHARGE — (Refer to Table 3A, 3B, 4A, or 4B.) All

units are factory charged with oil. Acceptable oil level for

each compressor is from Vs to Vs of sight glass (see Fig. 29,

page 38).

When additional oil or a complete charge is required, use

only Carrier-approved compressor oil.

Approved oils are:

Petroleum Specialties, Inc. — Cryol 150A (factory oil charge)

Texaco, Inc.

— Capella WF-32-150

Witco Chemical Co.

— Suniso 3GS

COMPRESSOR

OIL REQUIRED

Pts

L

06E-250

17

80

06E-265

21

99

06E-275

21

9.9

06E-299

19

90

Do not reuse drained oil, and do not use any oil that has

been exposed to atmosphere.

Adjust oil level in accordance with Start-Up, Preliminary

Oil Charge, page 38.

50