J--------- j p – Carrier 38AH044-134 User Manual

Page 40

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Check Compressor Oil Level — After adjusting the

refrigerant charge, allow each circuit to run fully loaded for

20 minutes. Running oil level should be */s to

'/3

up on the

sight glass. Stop the compressors at the field power supply

disconnect and check the crankcase oil level. Add oil only if

necessary to bring the oil into view in the sight glass. If oil

is added, run the circuit for an additional 10 minutes, then

stop and check oil level. If the level remains low, check the

piping system for proper design for oil return; also, check

the system for leaks.

If the initial check shows too much oil (too high in the

sight glass) remove oil to proper level. See Preliminary Oil

Charge for proper procedure for adding and removing oil.

When the above checks are complete, repeat the proce

dure with the unit operating at minimum load conditions.

UNITS 38AH044-084,124, AND 134 — For this minimum

load check, run the lead compressor of each refrigeration cir

cuit fully unloaded with the lag compressor not operating.

Unload the compressor(s) by turning the control set point

adjustment nut counterclockwise until the adjustment nut

stops. The unloader is now at 0 psig (0 kPag) set point. If

electrically actuated unloaders are installed, energize the so

lenoid to unload the compressor. Recheck the compressor

oil level as described in Check Compressor Oil Level above.

Return unloader to original setting after checks are

complete.

UNITS 38AH094,104 — For this minimum load check, the

lead compressor (Al, Bl) of each refrigeration circuit is un

loaded. See Table 15. The lag compressor (A2, B2 [38AH104

only]) of each refrigeration circuit must not be operating.

Unload the compressor(s) by turning the control set point

adjustment nut counterclockwise until the adjustment nut stops.

The unloader is now at 0 psig (0 kPag) set point. If electri

cally actuated unloaders are installed, energize the solenoid

to unload the compressor.

Return unloader to original setting after checks are

complete.

Final Checks — Ensure all safety controls are operat

ing, control panel covers are on, and the service panels are

in place.

ALL OUTDOOR FANS MUST BE OPERATING

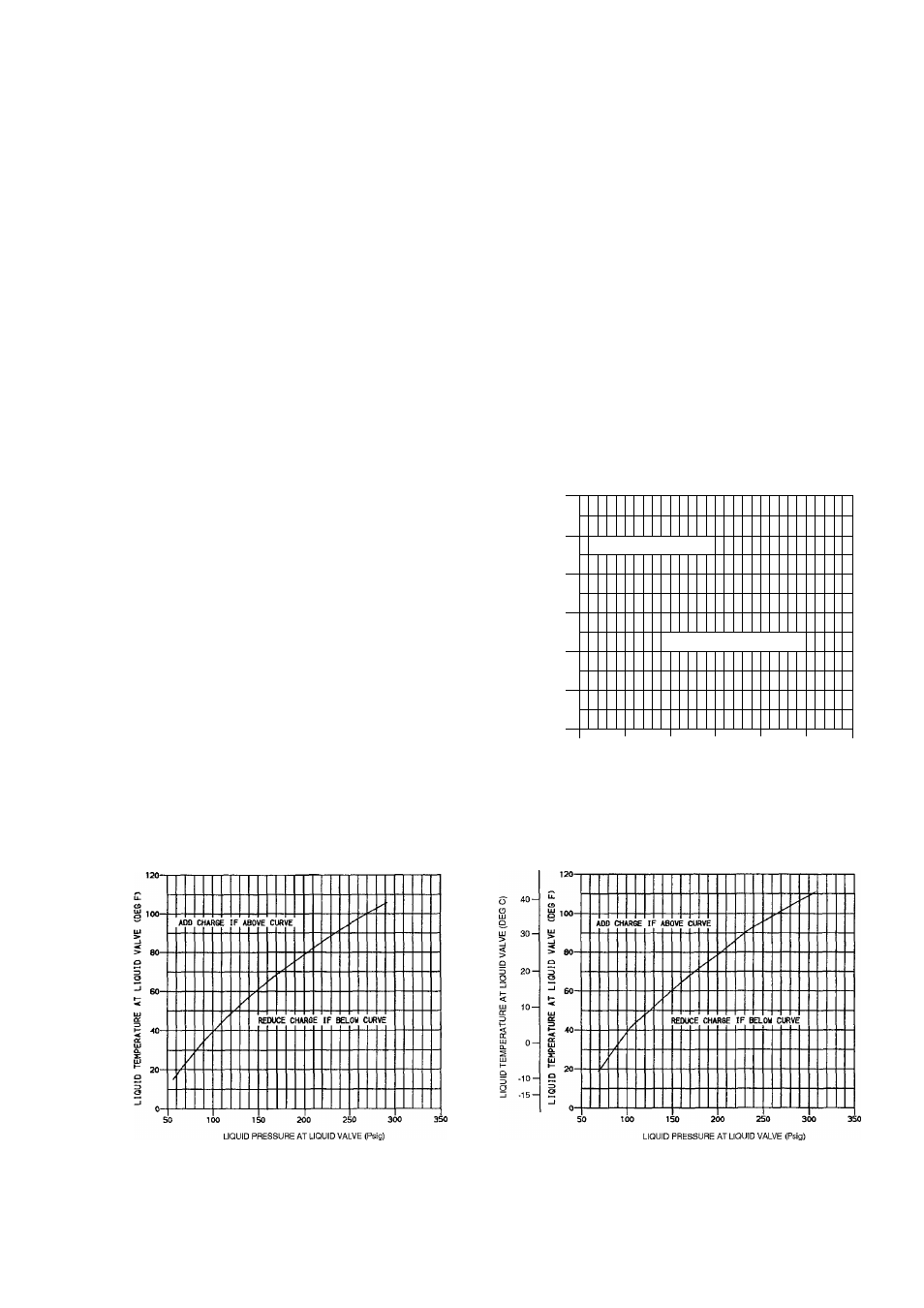

CIRCUIT A

CIRCUIT В

ADD CHARGE IF ABOVE CURVE

L

/

/-

/

REDUCE CHARGE tF вО-ОМ CURVE

100

150

200

250

300

LIQUID PRESSURE AT LIQUID VALVE (Psig)

1000

1500

2000

LIQU ID PRESSURE AT LIQUID VALVE (kPag)

5 -10-

О

□

-15-

I 01 1H

\k E II •

S V

;u

IV

/

¿

tE Ki Ж

c

и

1 IF

1 ■L

(

VE

/

T

100

150

200

250

300

LIQUID PRESSURE AT LIQUID VALVE (Psig)

~1

I

I

I

500

1000

1500

2000

LIQUID PRESSURE AT LIQUID VALVE (kPag)

Fig, 30 — Charging Chart — Unit 38AH044; 50/60 Hz — Duai Circuit

ALL OUTDOOR FANS MUST BE OPERATING

CIRCUIT A

CIRCUIT В

-

10

-

-

15

*

—j--------- j------------1

p

500

1000

1500

2000

LIQUID PRESSURE AT LIQUID VALVE (kPag)

_T_

500

1000

1500

2000

LIQUID PRESSURE AT LIQUID VALVE (kPag)

Fig. 31 — Charging Chart — Unit 38AH054; 50/60 Hz — Dual Circuit

40