Carrier 38AH044-134 User Manual

Page 46

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

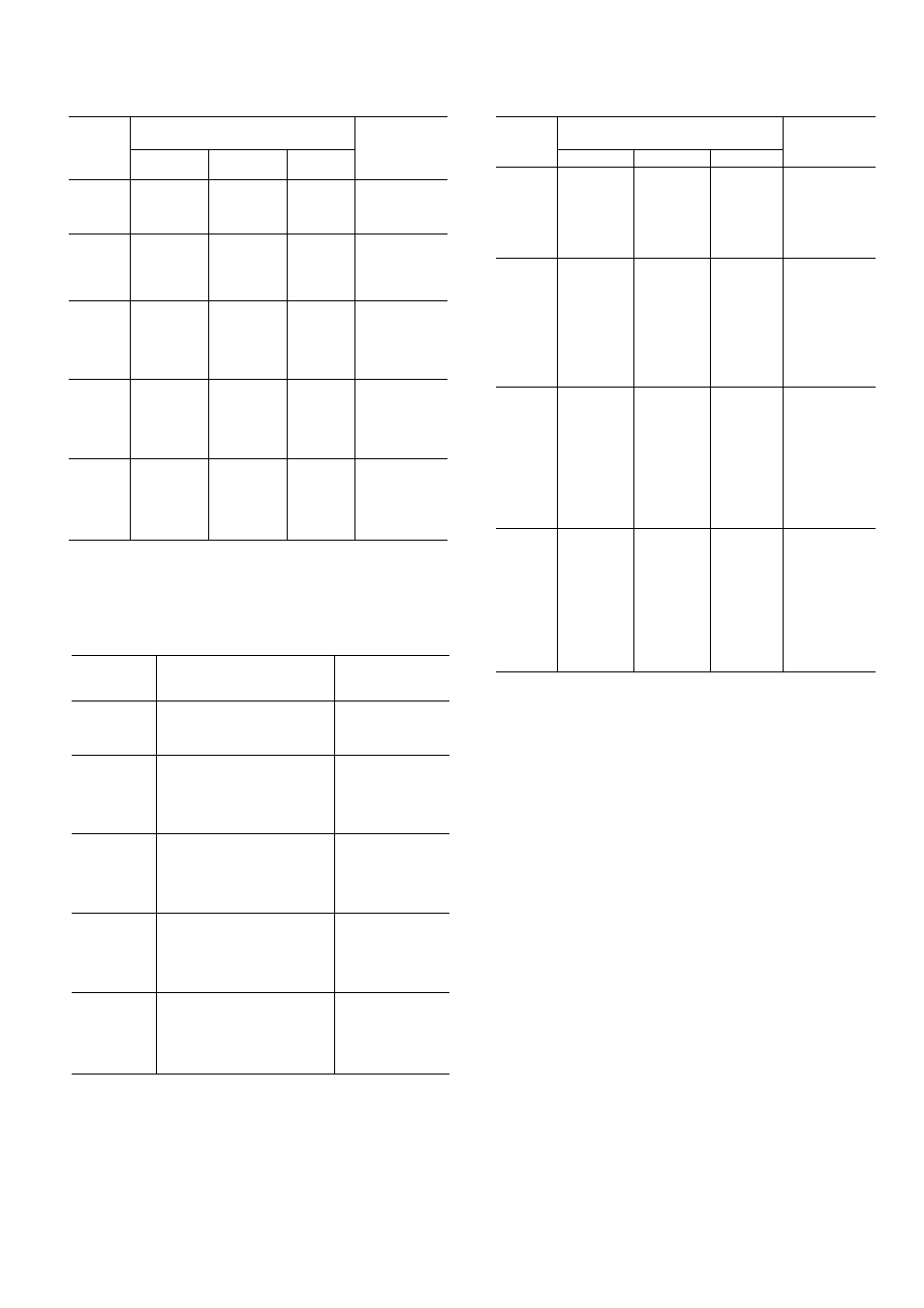

Table 19A — One 2-Stage Thermostat Capacity

Control for 38AH044-084 Dual-Circuit Units

Table 20 — One 2-Stage Thermostat Capacity

Control for 38AH094-134 Units

UNIT

38AH

QUANTITY OF LOADED

COMPRESSOR CYLINDERS

SYSTEM

CAPACITY

(%)

Circuit

A

Circuit

B

Total

4

4

8

100

044

2

4

4

0

6

4

75

50

2

0

2

25

4

6

10

100

2

6

8

79

054

2

4

6'

59

4

0

4

42

2

0

2

21

6

6

12

100

4

6

10

84

064

2

6

6

0

8*

6

68

48

4

0

4

32

2

0

2'

16

6

6

12

100

4

6

10

86

074

2

6

6

0

8*

6

72

43

4

0

4

29

2

0

2'

15

084

6

4

2

6

4

2

6

6

6

0

0

0

12

10

8'

6

4

2*

100

83

66

50

33

17

'Requires units with VAV (variabie air voiume) factory-suppiied

option

NOTE- Units have 2 independent refrigeration circuits. Circuit Ais lead

circuit.

Table 19B — One 2-Stage Thermostat Capacity

Control for 38AH044-084 Optional Single-Circuit Units

UNIT

38AH

QUANTITY OF

LOADED CYLINDERS

SYSTEM

CAPACITY

(%)

044

8

6

4

2

100

75

50

25

10

100

8

81

054

6

6

60

56

4

37

2'

19'

12

100

10

82

064

8

6

64

56

4

36

2t

18

12

100

10

81

074

8

6

62

57

4

38

2t

19

084

12

10

8

6

4

2t

100

83

66

50

33

17

UNIT

38AH

QUANTITY OF LOADED

COMPRESSOR CYLINDERS

SYSTEM

CAPACITY

(%)

Ckt A

Ckt B

Total

10

6

16

100

10

4

14

85

10

2

12

70*

10

0

10

55

094

8

0

8

44

6

0

6

33

4

0

4

22

10

12

22

100

8

12

20

91

8

10

18

82

10

6

16

73

104

6

6

6

4

12

10

55

45

0

6

6

27

4

0

4

18

0

4

4

18

2f

0

2

9t

12

12

24

100

10

12

22

92

10

10

20

83

8'

10

18

75*

6

10

16

67

124

6

8*

14

58*

6

6

12

50

4

6

10

42

6

0

6

25

4

0

4

17

2'

0

2

8*

12

12

24

100

10

12

22

92

10

10

20

83

8'

10

18

75*

6

10

16

67

134

6

8*

14

58*

6

6

12

50

4

6

10

42

6

0

6

25

4

0

4

17

2*

0

2

8*

'Requires accessory unioader on lead 06E-265 compressor (At).

tRequires VAV (variable air volume) factory-installed option or ac

cessory unloader

’Requires VAV (variable air volume) unit or accessory unloader(s) field

installed on circuit lead compressor. Lead compressor is identified in

Table 16, page 39

tRequires field-installed accessory unloader on circuit lead compres

sor Lead compressor is identified in Table 16, page 39

NOTES-

1 Temperatures calculated with the minimum number of fans oper

ating per circuit

2 See Table 16, page 39, for information on lead and lag circuits

CONTROL SET POINT — Control set point (cylinder load

point) is adjustable from 0 to 85 psig (0 to 586 kPag). To

adjust the set point, turn the control set point adjustment nut

clockwise to bottom stop. (See Fig 46.) In this position, load-up

set point is 85 psig (586 kPag). Turn adjustment counter

clockwise to desired control set point. Every full turn clock

wise decreases the load-up set point by 7.5 psig (52 kPag).

PRESSURE DIFFERENTIAL — Pressure differential (dif

ference between cylinder load and unload points) is adjust

able from 6 to 22 psig (41 to 152 kPag). To adjust, turn pres

sure differential adjustment screw counterclockwise to back

stop position. The differential pressure is now adjusted to 6

psig (41 kPag). Turn the adjustment screw clockwise to ad

just the differential pressure. Every full clockwise turn in

creases the differential by 1.5 psig (10 kPag).

46