A caution, A warning, R—"t i – Carrier 38AH044-134 User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

The placement area must be level and strong enough to

support the operating weight of the unit (see Table 3A or

3B). When unit is in proper location, use of mounting holes

in base rails is recommended for securing unit to supporting

structure. For mounting unit on vibration isolators, a perim

eter support channel between the unit and the isolators is

recommended. Fasteners for mounting unit are field sup

plied. Be sure to mount unit level to ensure proper oil return

to compressors.

Units 38AH094-134 — Refer to Fig. 3-6 for airflow

clearances. Recommended minimum clearances are 6 ft

(1829 mm) for unrestricted airflow and service on sides of

unit, 5 ft (1524 mm) on ends, and unrestricted clear air space

above unit. Provide ample space to connect liquid and suc

tion lines to indoor unit. For multiple units, allow

8 ft (2440 mm) separation between units for airflow and

service.

A CAUTION

Do not forklift these units unless the unit is attached to

a skid designed for forklifting.

The placement area must be level and strong enough to

support the operating weight of the unit. See Table 4A

or 4B. Refer to the following paragraphs for the proper place

ment of the unit.

Units 38AH094.104 — For mounting units on vibration iso

lators, a perimeter support channel is required between the

unit and the support isolators. The perimeter support chan

nel must be sized to support the fully assembled unit. Do not

support units on individual isolation supports. Support chaii-

nel, hardware, and fasteners are field supplied. When unit is

in proper location, level unit and bolt into position with field-

supplied bolts.

Units 38AH124.134 — For ease of shipment and handling,

unit 38AH124 is shipped as 2 modules (124A and 124B)

and unit 38AH134 is shipped as 2 modules (134A and 134B).

The modules must be connected at the final installation site

with the factory-shipped piping and sheet metal trim kit mounted

on Module 124A or 134A. See Fig. 7.

A WARNING

Do not move assembled 38AH124 or 134 units as a single

assembly. Always move modules individually during in

stallation or at any other time.

Mark installation site for placement of Modules 124 A and

124B or Modules 134A and 134B. See Table 4A or 4B for

final assembled dimensions. A service space of 24 in.

(610 mm) is required between the 2 modules for piping and

sheet metal trim installation.

Place Module 124A or 134A in position, ensuring that the

control box is at the end opposite the service space. See

Fig. 8.

Remove sheet metal and tubing from Module 124A or 134A

sheet metal trim kit (Fig, 7). Remove sheet metal cover pan

els from return-bend end of unit facing the service space.

See Fig. 8. These panels may be discarded or saved for re-

installation if module is moved from site. See Fig. 9.

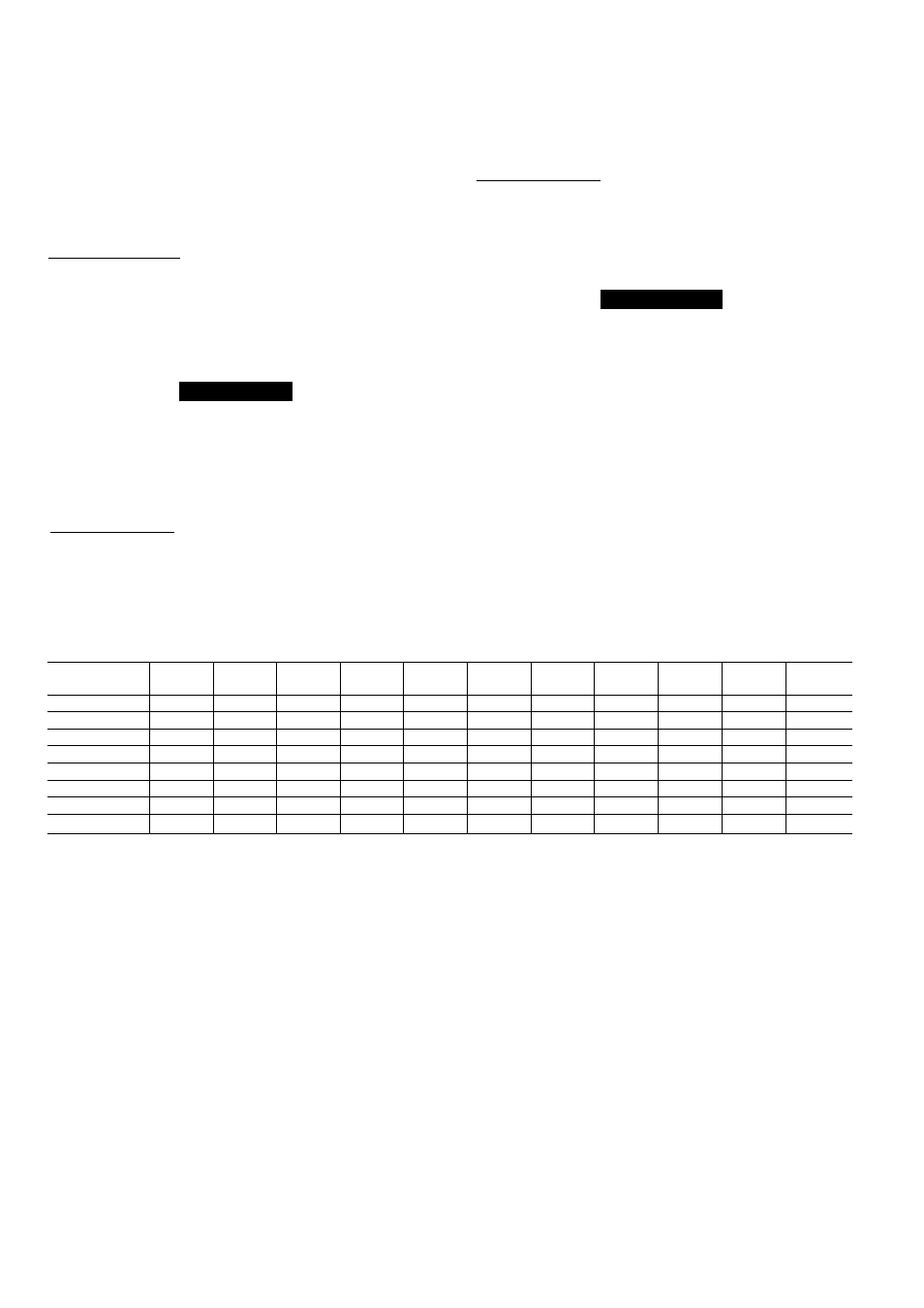

Table 1 — Rigging Center of Gravity — in. (mm)

UNIT

38AH

044

054

064

074

084

094

104

MODULE

124A

MODULE

124B

MODULE

134A

MODULE

134B

Dimension X

49 (1232) 48 (1224) 50 (1260) 57 (1443) 57 (1448) 66 (1676) 63 (1600) 50 (1260)

-

50 (1260)

—

Dimension Y

39 (984)

39 (978)

38 (968)

39 (993)

39 (991)

31 (787)

34 (851)

38 (968)

—

38 (968)

—

Dimension X-C

49 (1234) 48 (1229) 50 (1261) 56 (1425) 56 (1422) 66 (1676) 63 (1600) 50 (1260)

—

50 (1260)

—

Dimension Y-C

39 (993)

39 (991)

39 (986)

40 (1006) 40 (1008) 31 (787)

34 (851)

39 (986)

—

39 (986)

—

Dimension K

—

—

—

—

—

—

—

50 (1260)

—

57(1443)

Dimension L

—

—

_

—

—

—

—

—

38 (968)

—

39 (993)

Dimension K-C

—

—

—

—

—

—

—

—

50 (1260)

—

56 (1425)

Dimension L-C

—

—

—

—

—

—

—

—

39 (986)

—

40 (1006)

LEGEND

— — Not Applicable

C

— Copper Fin Coils

Y

A

CONTROL

BOX

END

COMPR

COMPR

r—"T I

COMPR

COMPR

CONTROL

BOX

END

TOP VIEW, TYPICAL

124, 134 ONLY