A caution, Adjust refrigerant charge – Carrier 38AH044-134 User Manual

Page 39

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Preriminary Charge — Refer to GTAC n (General Train

ing Air Conditioning), Module 5, Charging, Recovery, Re

cycling, and Reclamation for charging procedures. Using the

liquid charging method and charging by weight proced^ure,

charge each circuit with the amount of R-22 listed in Table

3A, 3B, 4A, or 4B.

A

CAUTION

Never charge liquid into the low-pressure side of sys

tem. Do not overcharge. During charging or removal of

refrigerant, be sure indoor-fan system is operating.

Start Unit — The field disconnect is closed, the fan cir

cuit breaker is closed, and the space thermostats are set above

ambient so that there is no demand for cooling. Only the

crankcase heaters are energized.

Close the compressor circuit breakers and then reset both

space thermostats below ambient so that a call for stage one

cooling is ensured. Lead refrigeration circuit ther

mostat TCI must be set to call for cooling at a lower tem

perature than lag refrigeration circuit thermostat TC2.

See Table 15 for lead/lag circuits on all units. Now set TC2

for cooling.

NOTE: Do not use circuit breakers to start and stop the com

pressor except in an emergency.

38AH044-084 DUAL-CIRCUIT UNITS — Start-up of lead

compressor A1 (Table 16) will be delayed from 12 seconds

to 5Vi minutes from the time the call for cooling is initiated

by TCI. After the lead compressor starts, close the TC2 ther

mostat to start lag circuit compressor Bl. Compressor B1

will start a minimum of 60 seconds after thermostat TC2 is

closed.

38AH044-084 OPTIONAL SINGLE CIRCUIT UNITS —

Start-up of lead compressor A1 (Table 16) is delayed from

12 seconds to 5V2 minutes from the time the call for cooling

is initiated by TCI. Closure of TC2 will actuate LLS-A2.

Lag compressor A2 is controlled by D-D2 timer contacts and

capacity control pressure switches (CCPSs) which monitor

compressor suction pressure. The lag compressor starts ap

proximately

2

V

2

minutes after the lead compressor starts if

the suction pressure is above the CCPS set point.

38AH094,104 UNITS — Start-up of lead circuit A,

compressor A1 (Table 16) is delayed from 12 seconds to

5

V

2

minutes from the time the call for cooling is initiated.

After lead circuit A, compressor A1 starts, close refrigera

tion circuit thermostat TC2 to start lag circuit B, lead com

pressor BL Start-up of compressor Bl is delayed from

12 seconds to 5

'/2

minutes. (Circuit B of unit 38AH094 has

only one compressor.)

Each circuit’s lead compressor start-up is controlled by

the unit control timer. The circuit’s lag compressor start-up

is controlled by the D-D2 timer contacts and capacity

control pressure switches (CCPSs) which monitor compres

sor suction pressure. The circuit’s lag compressor will start

approximately 2

*/2

minutes after a call for cooling if com

pressor pressure is above CCPS set point.

38AH124,134 UNITS — Start-up of the lead circuit

(Module 124A or 134A) lead compressor A1 (Table 16) is

delayed from 12 seconds to

5

V

2

minutes from the time the

call for cooling is initiated by TCI. Lag compressor A2 is

controlled by D-D2 timer contacts and capacity control pres

sure switches (CCPSs) which monitor compressor suction

pressure. The lag compressor starts approximately

2

V

2

min

utes after the lead compressor starts if the suction pressure

is above the CCPS set point.

After the lead circuit (Module 124A or 134A) lead com

pressor A1 (Table 16) starts, close the TC2 thermostat to start

the lag circuit (Module 124B or 134B) lead compressor (Al).

Lag circuit compressor Al start-up is delayed from 12 sec

onds to

5

V

2

minutes from the time the call for cooling is

initiated by TC2. Lag compressor A2 is controlled by D-D2

timer contacts and CCPSs which monitor compressor suc

tion pressure. Lag compressor A2 starts approximately 2Vi

minutes after lead compressor Al starts if the suction pres

sure is above the CCPS set point.

Adjust Refrigerant Charge

A

CAUTION

Never charge liquid into the low-pressure side of sys

tem. Do not overcharge. During charging or removal of

refrigerant, be sure indoor-fan system is operating.

With all fans operating, and all compressors on the cir

cuit being serviced operating at full capacity, adjust the re

frigerant charge in accordance with the unit charging charts

located on the inside of the control box doors and in Fig.

30-43. Charge vapor into compressor low-side service port

located above oil pump crankshaft housing. Measure pres

sure at the liquid line service valve, making sure a Schrader

depressor is used if required. Also, measure liquid line tem

perature as close to the liquid service valve as possible. Add

charge until the pressure and temperature conditions of the

charging chart curve are met. If liquid pressure and tempera

ture point fall above curve, add charge. If liquid pressure

and temperature point fall below curve, reduce the charge

until the conditions match the curve.

If the sight glass at location A (Fig. 11 and 12) is cloudy,

check refrigerant charge again. Ensure all fans and com

pressors on the circuit being serviced are operating. Also

ensure maximum allowable liquid lift has not been

exceeded.

If the sight glass at location A is clear and the sight glass

at location B is cloudy, a restriction exists in the line be

tween the 2 sight glasses. Check for a plugged filter drier or

partially open solenoid valve. Replace or repair, as needed.

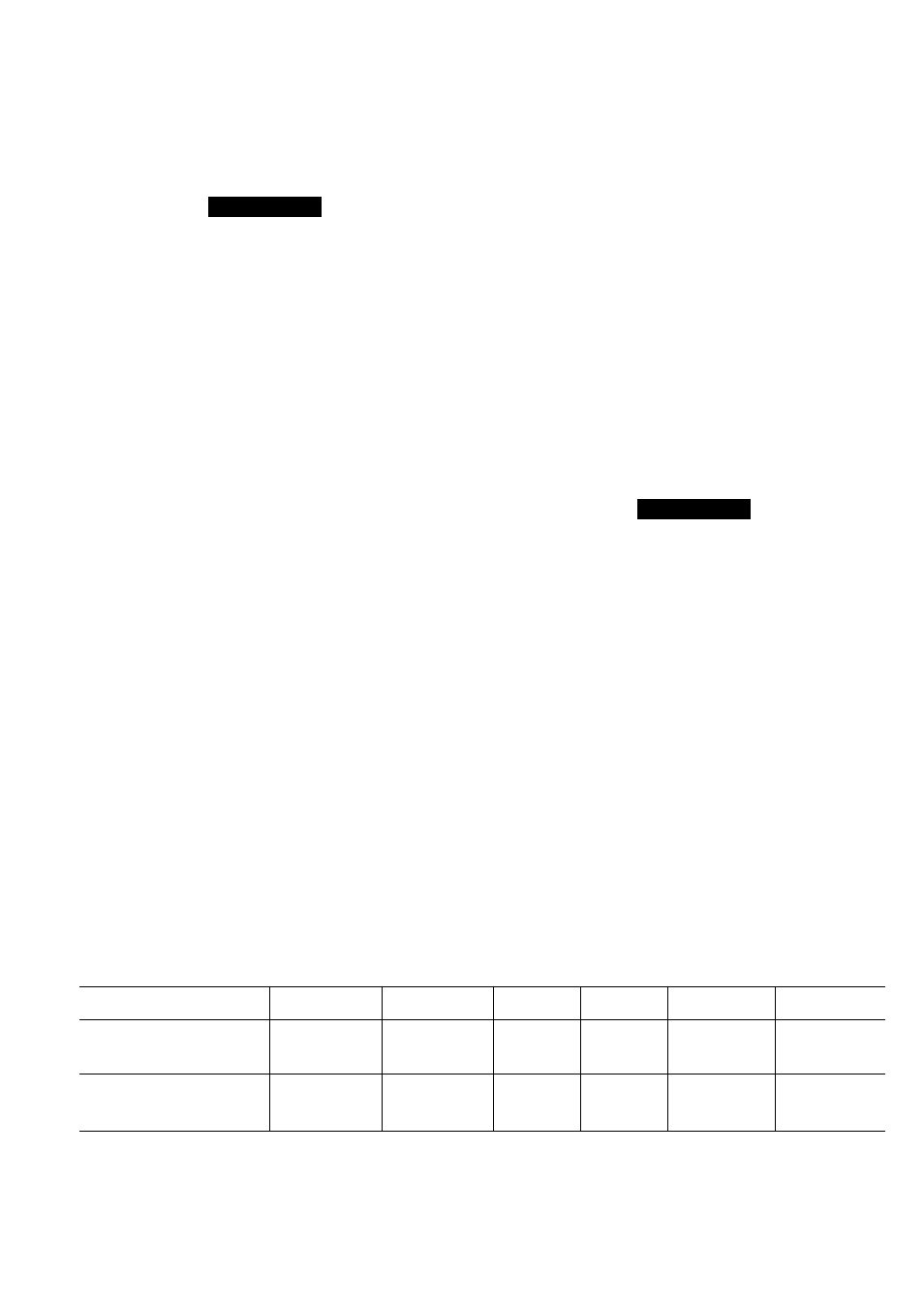

Table 16 — Index of Lead/Lag Circuits and Compressors

UNIT 38AH

044-084

STD

044-084

OPT

094

104

124

134

LEAD CIRCUIT

A

A

A

A

Module

124A

Module

134A

Compressor, Lead

Compressor; Lag

AJ

At

A2

At

A2

At

A2

Al

A2

Al

A2

LAG CIRCUIT

В

t

В

В

Module

124B

Module

134B

Compressor, Lead

Compressor; Lag

Bl

*

Bl

*

Bl

B2

Al

A2

Al

A2

4

^

LEGEND

OPT

— Optional Single-Circuit Units

STD

— Standard Dual-Circuit Units

‘Circuit has only one compressor

fUnits have only one circuit

39