Step 5 — install accessories, Pre-start-up, System check – Carrier 38AH044-134 User Manual

Page 37: A caution, Start-up

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

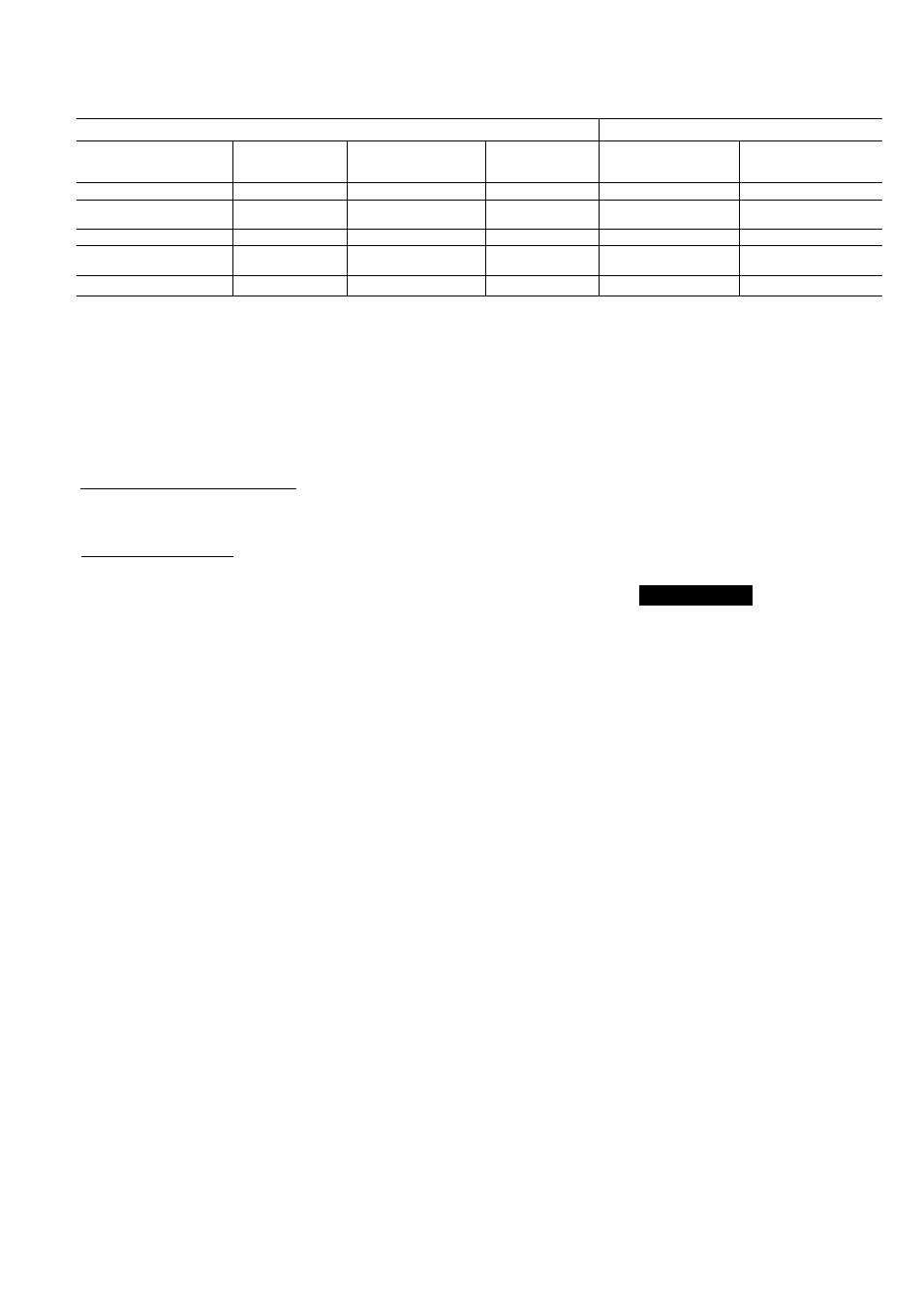

Table 15 — Main Power Connection and Control Circuit Wiring

MAIN POWER CONNECTION

CONTROL CIRCUIT

Electrical

Characteristics

(V-Ph-Hz)

Qty

Terminal

Blocks

Qty

Parallel

Conductors*

Max Wire

Size

(kcmil)

Control Power

(V)

Safety Circuit

(V)

208/230-3-60

1

6

500

115f

24

460-3-60

575-3-60

1

3

500

115t

24

230-3-50

1

6

500

230

24

380-3-60

380/415-3-50

1

3

500

230

24

346-3-50

1

3

500

200

24

LEGEND

kcmil —

Thousand Circular Mils

‘Conductors are from the safety disconnect.

tControl power is accomplished with a step-down transformer where primary voltage is field voltage

Step 5 — Install Accessories

LOW-AMBIENT OPERATION

Units 38AH044-084. 124, and 134 — If operating tempera

tures below 55 E (13 C) are expected, Motormaster® III fan

motor control is recommended. Refer to separate installa

tion instructions for low-ambient operation guidelines.

Units 38AH094 and 104 — If operating temperatures below

45 F (7 C) are expected, Motormaster III fan motor control

is recommended. Refer to separate installation instructions

for low-ambient operation guidelines.

MISCELLANEOUS ACCESSORIES — For applications re

quiring special accessories, the following packages are avail

able; condenser coil hail guard package, gage panel, unloader

package, unloader conversion kits, sound reduction pack

age, condenser coil protective grilles, compressor security

grilles, ModuPaneFM control, and thermostat transformer re

lay package.

PRE-START-UP

IMPORTANT: Before beginning Pre-Start-Up or Start-

Up, review Start-Up Checklist at the back of this pub

lication. The Checklist assures proper start-up of a unit

and provides a record of unit condition, application re

quirements, system information, and operation at ini

tial start-up.

Do not attempt to start the air-conditioning system until

following checks have been completed.

System Check

1. Check all system components, including the air

handling equipment. Consult manufacturer’s instruc

tions. If the unit has field-installed accessories, be sure

all are properly installed and wired correctly. Refer to

unit wiring diagrams.

2. Backseat (open) compressor suction and discharge shut

off valves. Close valves one turn to allow refrigerant pres

sure to reach the test gages.

3. Open liquid line service valves.

4. Check tightness of all electrical connections.

5. Oil should be visible in the compressor sight glasses.

See Fig. 29. An acceptable oil level in the compressor

is from Vs to Vs of sight glass. Adjust the oil level as

required. No oil should be removed unless the crank

case heater has been energized for at least 24 hours. See

Start-Up section on page 38, Preliminary Oil Charge,

for Carrier-approved oils.

6. Electrical power source must agree with unit

nameplate.

A

CAUTION

Crankcase heaters on all units are wired into the control

circuit, so they are always operable as long as the main

power supply disconnect is on (closed), even if any safety

device is open. Compressor heaters must be on for 24

hours prior to the start-up of any compressor.

7. Crankcase heaters must be firmly locked into compres

sors, and must be on for 24 hours prior to start-up.

8. Fan motors are 3-phase. Check rotation of fans during

first start-np check. Fan rotation is clockwise as viewed

from top of unit. If fan is not turning clockwise, reverse

2 of the power wires.

9. Check compressor suspension. On units 38AH044-084,

124, and 134, snubber washers (for noise suppression)

can be moved with finger pressure. On units 38AH094

and 104, rails allow compressors to float freely on com

pressor rail springs.

10. On 38AH074,084 single-circuit units and Modnle

38AH134B, ensure that the packaging block located be

tween the oil eqnalization tube and the compressor cross

brace has been removed.

START-UP

Compressor crankcase heaters must be on for 24 hours

before start-up. To energize the crankcase heaters, set the

space thermostat above the ambient so there will be no de

mand for cooling. Close the field disconnect and turn on the

fan circuit breakers. Leave the compressor circuit breakers

off/open. The crankcase heaters are now energized.

37