Step 3 — make refrigerant piping connections, A caution – Carrier 38AH044-134 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Step 3 — Make Refrigerant Piping

Connections

A CAUTION

The field-supplied liquid line solenoid valve must be in

stalled at the evaporator to avoid possible compressor

damage during unit operation. See Fig. 11 (for 38AH044-

084 dual-circuit and 38AH094-134 units), or Fig. 12 (for

38AH044-084 optional single-circuit units).

The units have large suction lines to minimize friction losses.

The units also have the ability to operate at low capacity.

Because of these capabilities, use special care with suction

piping and suction risers to ensure proper compressor oil

return under all operating conditions. Maximum allowable

vertical separation between the condensing unit and the evapo

rator is shown in Table 5. Size suction lines in accordance

with Tables 6A or 6B through 9A or 9B and Fig. 13. Mount

liquid line solenoid valve just ahead of the TXVs (thermo

static expansion valves) which will be mounted at the

evaporator. See Fig. 11 (for 38AH044-084 dual-circuit and

38AH094-134 units) or Fig. 12 (for 38AH044-084 optional

single-circuit units).

Fig. 9 — Typical Module with Cover Panels

Removed

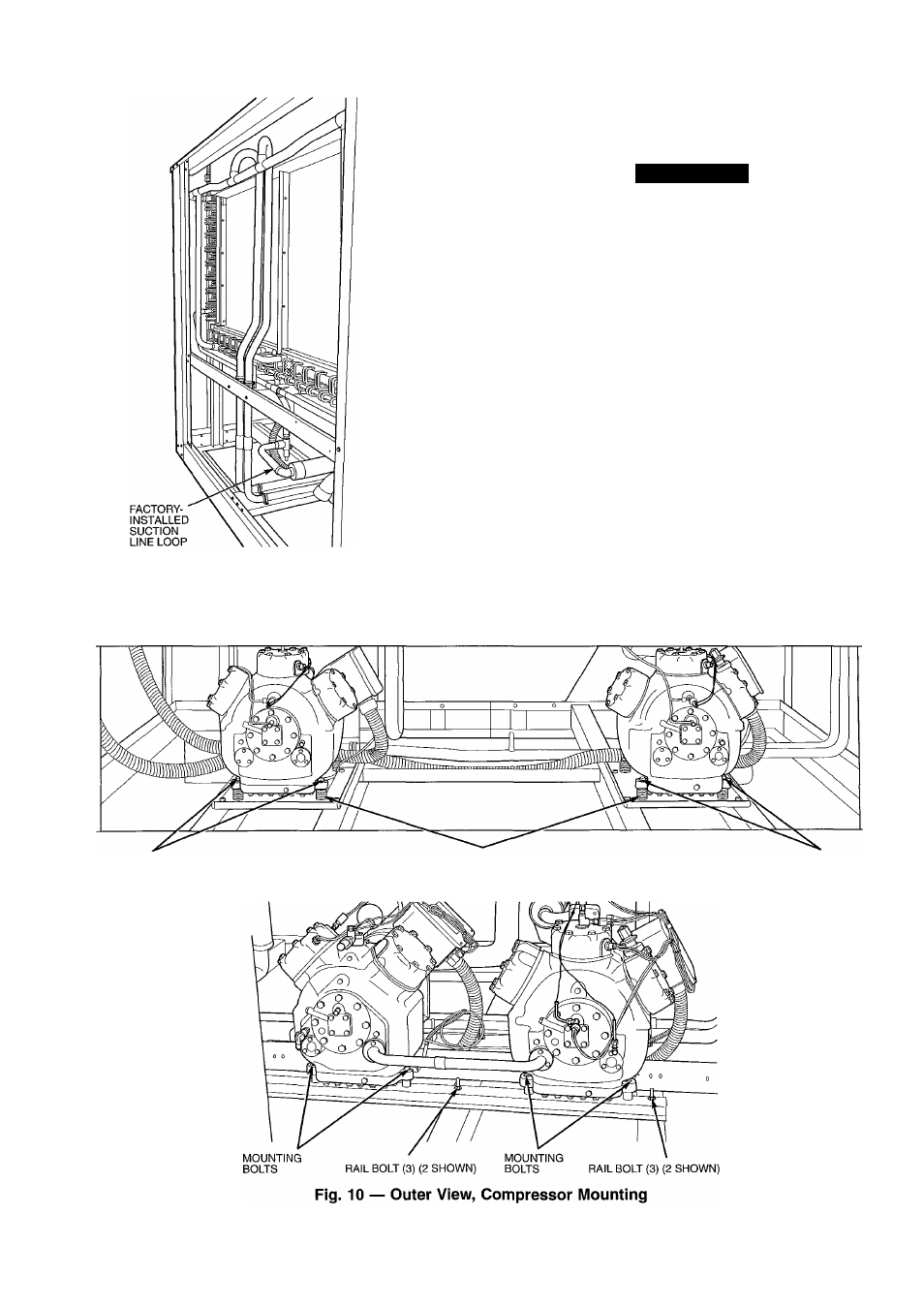

38AH044-084,124,134

SHIPMENT BOLTS

MOUNTING SPRINGS

38AH094,104

SHIPMENT BOLTS

13