Carrier 38AH044-134 User Manual

Page 47

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

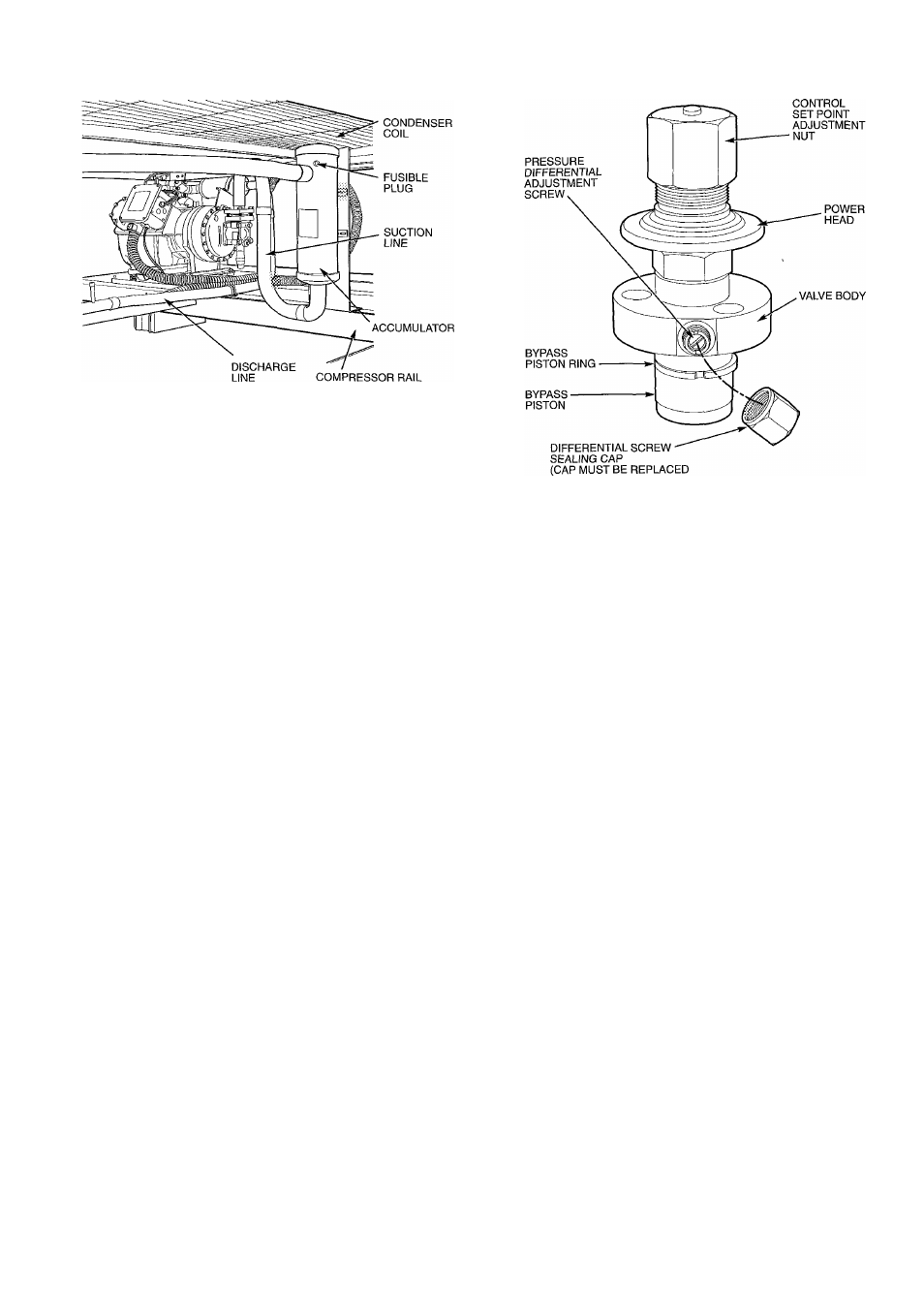

Fig. 45 — Accumulator and Fusible Plug

Timer Functions — (See Timer Cycle, Fig. 47.) Each

refrigeration circuit is controlled by an independent timer

which allows for the independent operation of each refrig

eration circuit.

NOTE: Unit 38AH044-084 optional single-circuit units have

one timer which controls the lead compressor. Lag compres

sor is controlled by CCPS (capacity control pressure switch).

SWITCH A — The timer is energized through contacts A-Al

or A-A2. This establishes the Time Guard® function which

prevents compressor short-cycling. Start of compressor is de-

i

layed approximately 5.5 minutes after shutdown.

^' SWITCH B — The compressor is initially energized through

contacts B-Bl.

SWITCH D — Contacts D-Dl provide a 2*/2-minute bypass

of the low-pressure switch at start-up for winter-start con

trol. On 38AH044-084 optional single-circuit units, contacts

D-D2 control start-up of compressor A2.

SWITCH E — Contacts E-EI provide a 40-second bypass

of the oil pressure switch at start-up. If oil pressure does not

build to the required minimum pressure in 40 seconds, the

compressor shuts down and the control circuit locks out.

On 38AH044-084 dual-circuit and 38AH094,104 units, lag

circuit B start-up is delayed 60 seconds after a call for cool

ing is made to the circuit. This prevents compressor(s) in

both lead and lag circuits from starting at the same time.

Control Circuit Reset — The control circuit locks out

if the unit shuts down because of low oil pressure, high dis

charge gas temperature (DGT), or excessive high-side pres

sure. To reset the control circuit, open and close the fan cir

cuit breaker (FCB). This resets the timer, and the unit restarts

under Time Guard control. At start-up, if the low-pressure

switch (EPS) does not close after 2'/2 minutes, the unit shuts

down. When the pressure builds enough for the EPS to cut

in, the control circuit is energized automatically and start-up

proceeds under Time Guard control.

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 46 — Pressure-Actuated Capacity Control Valve

CONTROL

Sequence of Operation — Units are controlled with

electromechanical components. Each refrigeration circuit

(except 38AH044-084 optional single-circuit units) is oper

ated by an independent timer which controls the operation

sequence of each circuit.

On a call for cooling, first stage cooling thermostat TCI

closes. Condenser fans and timer (TM) are energized. After

approximately 7 seconds, timer contacts E-El close. Ap

proximately 12 seconds after TCI closes, normally-open timer

contacts B-B1 close for 1 second. This energizes compres

sor A1 contacts CAl and starts the compressor. At the same

time, solenoid drop relays (SDRs) and liquid line solenoid

valve no. 1 (EES-A for 38AH044-084 dual-circuit units;

EES-Al for all other units) open, and timer relay no. 1 (TR2)

is energized. Normally open TR2 contacts close, completing

a circuit around B-Bl and through compressor A1 contac

tors to maintain compressor operation when B-Bl contacts

open. Contacts E-El remain closed for approximately 40 sec

onds to bypass the oil pressure switch (OPS). If oil pressure

is insufScient when contacts E-El open, the compressor stops,

the timer cycles off, and the control circuit locks out. At start

up, timer contacts D-Dl are closed, bypassing low-pressure

relay contacts EPR-A for 21/2 minutes. This provides a win

ter start-up feature.

Approximately 2V2 minutes after TCI closes, timer con

tacts D-Dl open and D-D2 close. If pressure is insufficient

to close the low-pressure switch, the low-pressure switch re

lay is open, the compressor shuts down, and the Time Guard

control is initiated. (Time Guard control prevents compres

sor from restarting for 5 minutes after the demand for cool

ing is satisfied.)

47