3 condenser fans 3.4 coil maintenance, 0 maintenance and service procedures (cont'd), 4 coil maintenance – Reznor MAPS - A,B,C Users Manual User Manual

Page 8: 3 condenser fans, 2 drive components cont'd)

Form O-MAPSIII&IV Cabinets A/B/C, Page 8

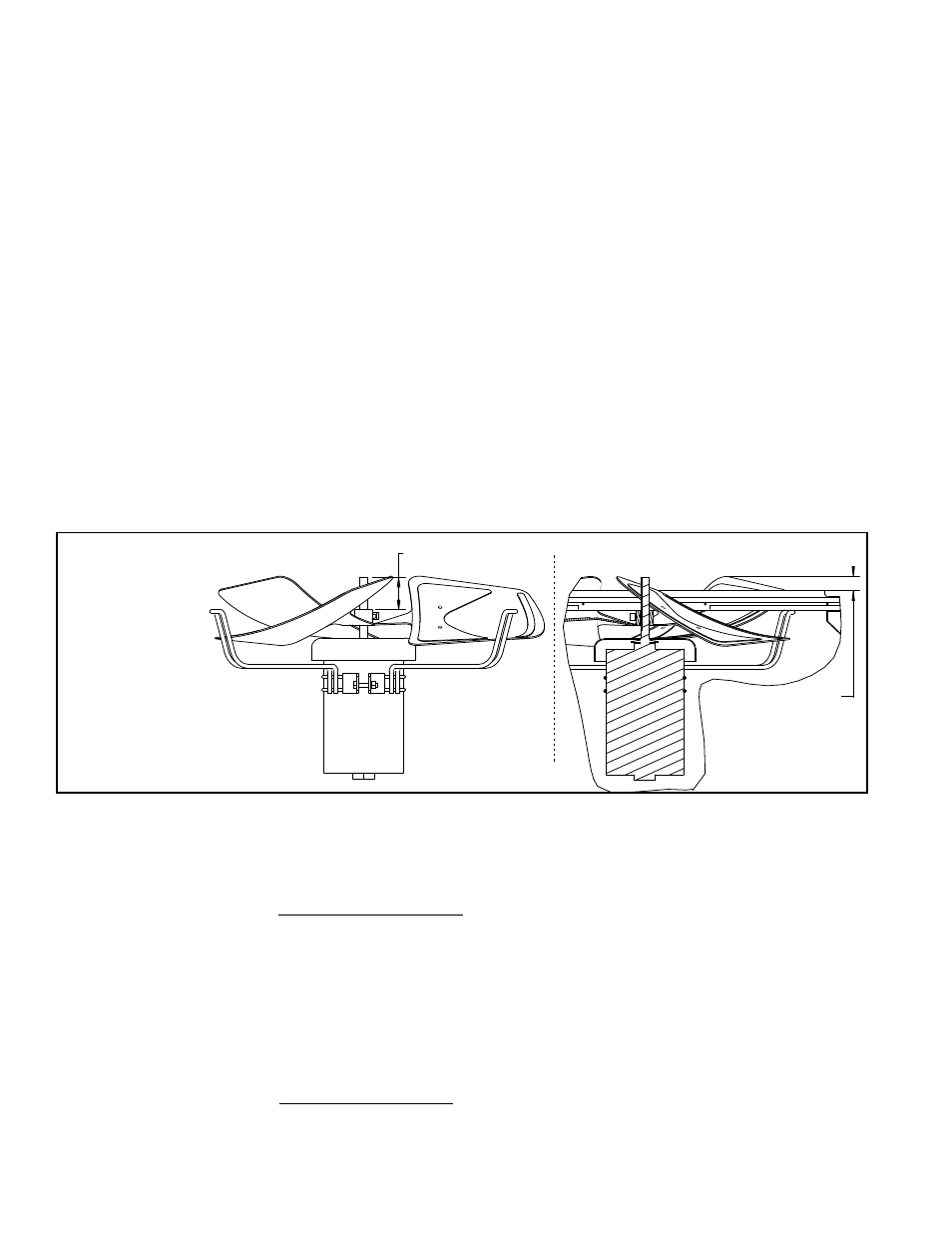

2-1/2” (63.5mm)

Fan and Motor Assembly

showing Fan Blade Position

Cross-section of Installed Fan and Motor

Assembly showing Cabinet Top

1.76” (44.7mm)

Top of Fan Blade

to Top of the

Cabinet Top Panel

Fan rotation is

clockwise.

FIGURE 3 -

Condenser

Fan Assembly

Dimensions

and Rotation

3.4 Coil

Maintenance

The MAPS

®

cooling system is equipped with space-saving MACROCHANNEL

®

coils.

Inspect all cooling system coils at the beginning of the cooling season or more often if

needed. Follow the cleaning instructions below. If additional cleaning is required or if a

coil must be removed for any reason, consult the factory. Be prepared to provide rating

plate and specific installation information.

Condensing Coil Access - The condensing coils are visible on the side of the unit

(below the condenser fans). For additional access for inspection and maintenance,

remove the tubing access panel (See

FIGURE 1, page 5.).

3.0 Maintenance

and Service

Procedures

(cont'd)

3.3 Condenser Fans

Depending on the size, there are two, three, or four fans in the condenser section. If

parts need to be replaced, use only factory authorized replacement parts. See

FIGURE

3 for assembled dimensions and proper fan rotation.

Condenser

Coil Cleaning

Instructions:

1. Verify that the electrical power has been turned off and the disconnect switch locked.

2. Use a soft brush to remove any dirt and debris from the coils.

3. Spray with cold or warm (not hot) water and a cleaning solution (non-acid based coil

cleaner is recommended). Due to possible damage to the coil, DO NOT use high

pressure spray.

4. When clean, rinse with cool, clean water.

Evaporator Coil Access - The evaporative coils can be accessed by opening the coil

cabinet door.

Inspect coils for debris, dirt, grease, lint, pollen, mold, or any element which would

obstruct heat transfer or airflow. Inspect coils and tubing for physical damage. Inspect

Belts (cont'd) - Blower systems are equipped with either Power Twist Plus

®

linked

blower belt or a solid belt. The linked belts are designed in sections allowing for easy

sizing and adjustment. The belt is sized at the factory for the proper tension. If the belt

needs adjustment, the recommended method of shortening the belt length is to count

the number of links and remove one link for every 24. (A link is made up of two joining

sections of belt. For easier removal of links, turn the belt inside out. But be sure to turn

it back before installing.)

If equipped with a solid belt, adjust the belt tension by turning the adjusting screw on

the motor base until the belt can be depressed 1/2" (13mm) on each side. After correct

tension is achieved, re-tighten the locknut on the adjustment screw.

Proper belt tension is important to the long life of the belt and motor.

Be sure belts are aligned in the pulleys. If a belt is removed or replaced, be sure the

directional arrows on the belt match the drive rotation.

Motor and Blower - Inspect the motor mounts periodically. Remove dust and dirt accu-

mulation from the motor and wheel.

The blower has cast iron, pillowblock, sealed bearings. Under most operating condi-

tions, re-lubrication is unnecessary. If lubrication is required, use a lubricant compat-

ible to Shell Alvania #2 (lithium base - Grade 2). Operating temperature range is -30

to 230°F.

If any drive parts need to be replaced, use only factory-authorized replacements

designed for the application.

3.2 Drive

Components

Cont'd)