Reznor MAPS - A,B,C Users Manual User Manual

Page 27

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 27

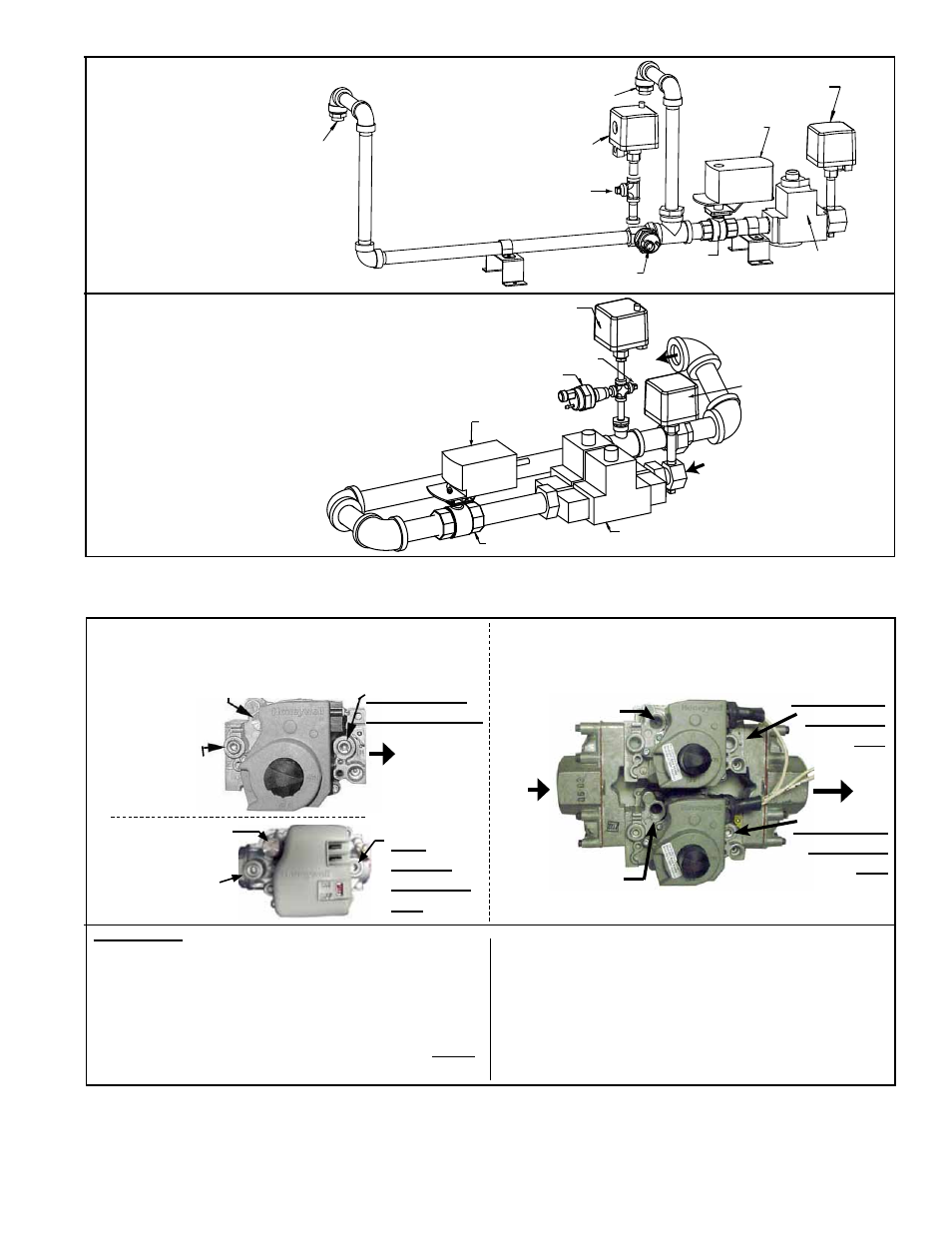

Optional High Gas

Pressure Switch

Optional Low

Gas Pressure

Switch

Dual, Single-Stage Gas Valve

Ball Valve

Transducer

From Gas

Supply

To

Burner

Manifold Pressure Tap

Ball Valve

Actuator

FIGURE 15C -

Components in the

Heat Section Gas

Train - MAPS

®

III&IV

Cabinet C (Heat

Section Sizes 400,

500, 600, 700)

Single-Stage Operating Gas Valve - All gas trains have either a single-stage or a dual single-stage safety gas valve.

The gas valve must be checked annually to ensure that it is shutting off gas flow completely; follow the instructions in

box below.

Instructions:

1. Locate the 1/8" NPT pressure tap or taps on the

combination valve.

2. Turn the knob(s) or switch to the OFF position to

prevent flow to the manifold. Connect a manometer to

each of the 1/8” outlet pressure taps (1 on the single-

stage valve; 2 on the dual single-stage valve).

NOTE:

Manometers (fluid-filled gauges) with inches water

column scale are recommended. Turn the heater off.

On the valve, turn the knob(s) or switch to the ON

position.

3. Use finger(s) to fully block the burner orifice(s).

Continue blocking for several seconds and observe

the manometers. If any pressure is indicated, the gas

valve is leaking. A leaking gas valve must be replaced

before the heater is put back in operation.

Orifice

Adapter

Orifice Adapter

Optional High Gas

Pressure Switch

Transducer

Ball

Valve

Single-Stage

Gas Valve

Ball Valve

Actuator

Optional Low Gas

Pressure Switch

Manifold Pressure Tap

FIGURE 15B -

Components in the

Heat Section Gas

Train - MAPS

®

III&IV

Cabinet B (Heat

Section Sizes 250

and 300)

FIGURE 16A - Top View of Single-Stage Gas

Valves used on Cabinet A or B Sizes

1/8” Outlet

Pressure

Tap

1/8” Outlet

Pressure

Tap

FIGURE 16B - Top View of Dual Single-Stage

Gas Valve used on Cabinet C Heat Section

1/8” Output

Pressure Tap

Inlet

Pressure Tap

Adjust Outlet

Pressure

Modulating Valve

The gas train also has a ball valve with an actuator to control gas flow. The ball valve

and actuator are located downstream of the regular or dual single-stage valve as

shown in

FIGURE 17A.

Carefully clean external dirt accumulation from the actuator.

Pressure

Adjustment

Pressure

Adjustment

1/8”

Output

Pressure

Tap

Inlet Pressure

Tap

Adjust Outlet

Pressure