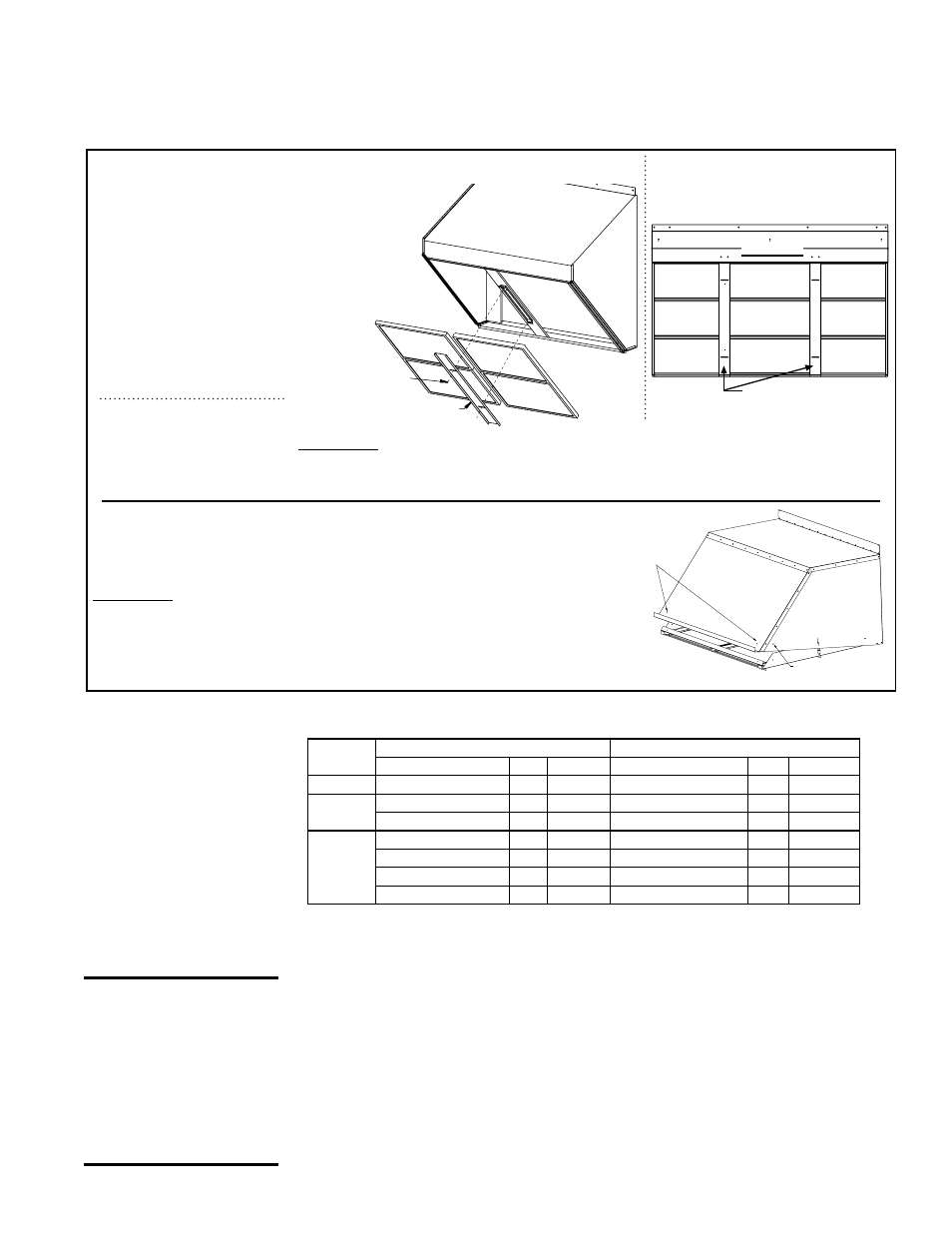

2 drive components, Figure 2a - removing filters from outside air hood, Permanent filters in the outside air hood – Reznor MAPS - A,B,C Users Manual User Manual

Page 7: Filters in an optional energy recovery module

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 7

Filter

Clamp

Filter

Filter

Wing Screw,

P/N 205707,

and Retainer,

P/N 205709

(2 each)

Filter

Filter

FIGURE 2A -

Removing Filters

from Outside

Air Hood

1" Permanent

Aluminum Filters

for Outside Air

Hood are listed by

Cabinet Size A, B, or C

(see cross-reference, page 6)

*A - (4) 16 x 20, P/N 101607

*B - (4) 16 x 25, P/N 101609

C - (3) 16 x 25, P/N 101609;

(6) 16 x 20,

P/N 101607

Cabinet Sizes A and B with Option AS16

Outside Air Hood

(Does not apply if

system includes

Option PE

power exhaust;

see below.)

Filter Clamps attach

with Wing Screws

P/N 205707

Filter

16x20x1

Filter

16x20x1

Filter

16x20x1

Filter

16x25x1

Filter

16x25x1

Filter

16x25x1

Filter

16x20x1

Filter

16x20x1

Filter

16x20x1

Inlet View

All Cabinet Size C with

either Outside Air Hood

Option AS16 or AS19

Instructions: Remove filters by loosening the wing screws and sliding the filter

clamp(s). Clean with soap and water, allow to dry, and replace. If it is more convenient

to keep an extra clean set of filters, quantities, filter sizes, and part numbers are listed.

* Apply only to Cabinet

Size A and B with outside

air hood Option AS16

.

DO NOT remove

this screw on

either side.

REMOVE one

screw on each side.

REMOVE

two

screws

on front.

FIGURE 2B - Removing Filters from Option AS19 Outside Air

Hood Installed on a Cabinet Size A or B with power exhaust

Option PE1 or PE2

Instructions: 1) Remove the four screws as illustrated. Lower the tray.; 2) Pull out

filters. Clean with soap and water. Allow to dry.; 3) Slide clean dry filters into tray.;

4) Re-position tray and replace screws.

1" Aluminum Filters:

**A - (4) 18 x 20, P/N 194903; **B - (4) 20 x 25, P/N 101610

** Apply only to Cabinet Size A and B with outside air hood Option AS19.

Permanent Filters in

the Outside Air Hood

If equipped with an outside air hood, there are 1" permanent, aluminum filters at the

entrance of the hood. The filters act as a moisture eliminator and bird screen. See

FIG-

URE 2A or 2B. When inspecting the inlet air filters, inspect the outside air hood filters.

If cleaning is needed, remove the filters, clean, rinse, dry and re-install.

Filters in an Optional

Energy Recovery

Module

If equipped with an energy recovery module (Option ER1A, ER1B, or ER1C), check

both inlet and exhaust filters. Replace as needed.

Cabinet

Size *

Inlet Air Filters (Merv 8)

Exhaust Air Filters (Merv 8)

Filter Type & Size

Qty

P/N

Filter Type & Size

Qty

P/N

A

Pleated 20x25x2

2

104113

Pleated 20x25x2

2

104113

B

Pleated 16x25x2

2

104112

Pleated 16x25x2

2

104112

Pleated 12x25x2

2

114320

Pleated 12x25x2

2

114320

C

Pleated 16x25x2

2

104112

Pleated 16x25x2

2

104112

Pleated 20x25x2

2

104113

Pleated 20x25x2

2

104113

Pleated 16x16x2

1

104109

Pleated 16x16x2

1

104109

Pleated 16x20x2

1

104110

Pleated 16x20x2

1

104110

*See cross-reference of

MAPS

®

Models by Cabinet

Size A, B, or C on page 6.

3.2 Drive

Components

CAUTION: If the

blower is unused

for more than three

months, bearings

with a grease fitting

should be purged

with new grease

prior to startup.

Setscrews - Check all of the setscrews (bearing/blower hubs and pulleys). Torque pul-

ley setscrews a minimum of 110 in-lb to 130 in-lb maximum.

A bearing hub setscrew for a 1-3/8" to 1-3/4" shaft requires a 5/16" socket and a tight-

ening torque of 165 in-lbs.

Belts - Check belt for proper tension and wear. If needed, follow instructions to adjust

belt tension. Replace worn belts.

Bearings - Bearings with a grease fitting should be lubricated twice a year with a high

temperature, moisture-resistant grease. (Type NLGI-1 or -2 standard grease is recom-

mended.) Be sure to clean the grease fitting before adding grease. Add grease with a

handgun until a slight bead of grease forms at the seal. Be careful not to unseat the

seal by over lubricating.

NOTE: If unusual environmental conditions exist (tempera-

tures below 32°F or above 200°F; moisture; or contaminants), more frequent lubrica-

tion is required.

NOTE: If it is more convenient to keep an extra clean set of filters, filter sizes and part numbers are shown in the illustration.