Iii models by size and compressor for each circuit, Step 10. system startup – Reznor MAPS - A,B,C Users Manual User Manual

Page 17

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 17

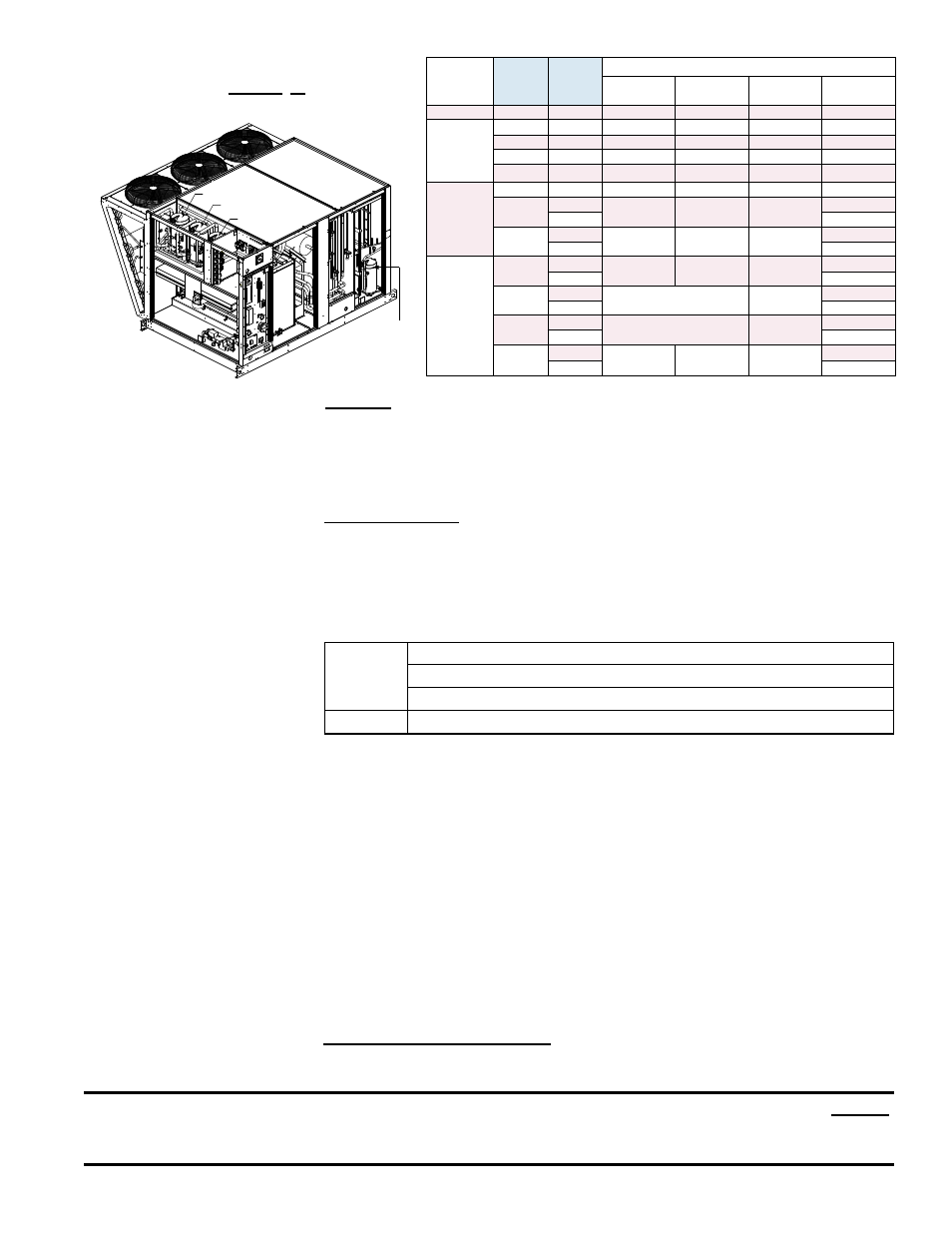

Approximate R410-A Refrigerant

Charge (lbs) for MAPS

®

III Models

by Size and Compressor for Each

Circuit

Cabinet

RCB/

RDCB/

RECB

RDB/

RDDB/

REDB

R410-A Charge (lbs) by Compressor Circuit

A

B

C

DH (Reheat)

A

060

084

4.3

4.0

N/A

4.2

A or B

078

102

5.2

4.0

N/A

4.2

090

114

5.7

4.8

N/A

4.2

118

142

6.5

4.8

N/A

4.2

136

162

6.5

5.7

N/A

4.2

B

160

184

6.5

4.8

4.2

4.2

186

210

5.2

6.0

5.2

4.2

222

6.0

200

224

5.2

6.0

6.0

4.2

236

6.0

C

190

248

8.0

10.5

N/A

9.5

262

10.0

216

272

11.0

8.5

9.5

288

10.0

298

354

11.0

11.0

9.5

370

10.0

410

468

10.5

10.5

10.5

9.5

482

10.0

Compressor B

Compressor C

Compressor A

Compressor

Dh (Reheat)

•

Step 10. System Startup

Assure voltage to compressor does not drop below minimum allowable voltage

(e.g. 187 volts for 230/208-3-60, 415 volts for 460/3/60, 518 volts for 575/3/60)

during the period the compressor is trying to start.

If a low voltage or voltage

imbalance condition exists, the electrical problem must be determined and

corrected prior to operating the unit.

Voltage Imbalance - Voltage imbalance is becoming a more common problem.

In a 3-phase system, excessive voltage imbalance between phases will cause

motors to overheat and compressors to fail. Maximum allowable imbalance is

2%. To determine voltage imbalance, measure and record the voltage of all three

phases. Take the measurements at the compressor terminals with the compressor

operating.

Voltage Imbalance Formula:

Key:

V1, V2, V3 = line voltages as measured

VA (Average )= (V1 + V2+ V3) / 3

VD = Line Voltage (V1, V2, or V3 that deviates farthest from average (VA)

Formula:

% of Voltage Imbalance = [100 (VA - VD)] / VA

If the imbalance is within the 2% tolerance, voltage imbalance is not a problem and

the system may be operated. If the imbalance exceeds the 2% tolerance, follow

the procedures below.

Solutions to Voltage Imbalance:

The cause for a voltage imbalance problem can originate at the power company or

can be caused inside the building. Try the following on-site solution to determine if

the problem can be easily resolved.

Roll the connections at the compressor terminals one forward. Connect the wire

now on Terminal 1 to Terminal 2, 2 to 3, and 3 to 1. Re-measure and re-calculate

the voltage imbalance. If the imbalance is within 2%, the system may be operated.

If the imbalance is not within tolerance, roll the connections one more forward.

Re-measure and re-calculate the voltage imbalance. If the imbalance is within

2%, the system may be operated. If the voltage imbalance still exceeds 2%, do

not start the system. Contact the building owner or person responsible to have an

electrician analyze the buildings's power supply and load distribution.

Power Supply Voltage Phasing - Connect refrigerant pressure gauges to the

suction and discharge lines of the compressors and an electric meter to the power

supply.

CAUTION: Be sure to connect pressure gauges to the suction and discharge lines before

system startup so that compressor rotation can be checked immediately. Scroll compressors

will be destroyed if allowed to operate in the wrong direction. See Hazard Levels, page 3.