0 maintenance/ service procedures (cont'd), 6 compressor maintenance (cont'd), Iv models by size and compressor for each circuit – Reznor MAPS - A,B,C Users Manual User Manual

Page 16

Form O-MAPSIII&IV Cabinets A/B/C, Page 16

•

Step 8. Check the Electrical System

After the system has been evacuated, reconnect the electrical plug to the

compressor or the wires to the compressor terminals. It is a normal practice to

replace all starting components any time a compressor is changed.

WARNING

Do not apply voltage to the compressor when the plug is

removed or terminals disconnected.

Crankcase Heater - Connect the crankcase heater. The crankcase heater is

energized continuously and is extremely important to proper compressor operation

and long life.

NOTE: See crankcase heater P/N's on page 12.

The crankcase heater must be energized for at least 24 hours before starting

the unit or after a power outage of more than 8 hours. Be sure to disable cooling

controls before turning on power to warm up crankcase heaters.

3.6 Compressor

Maintenance

(cont'd)

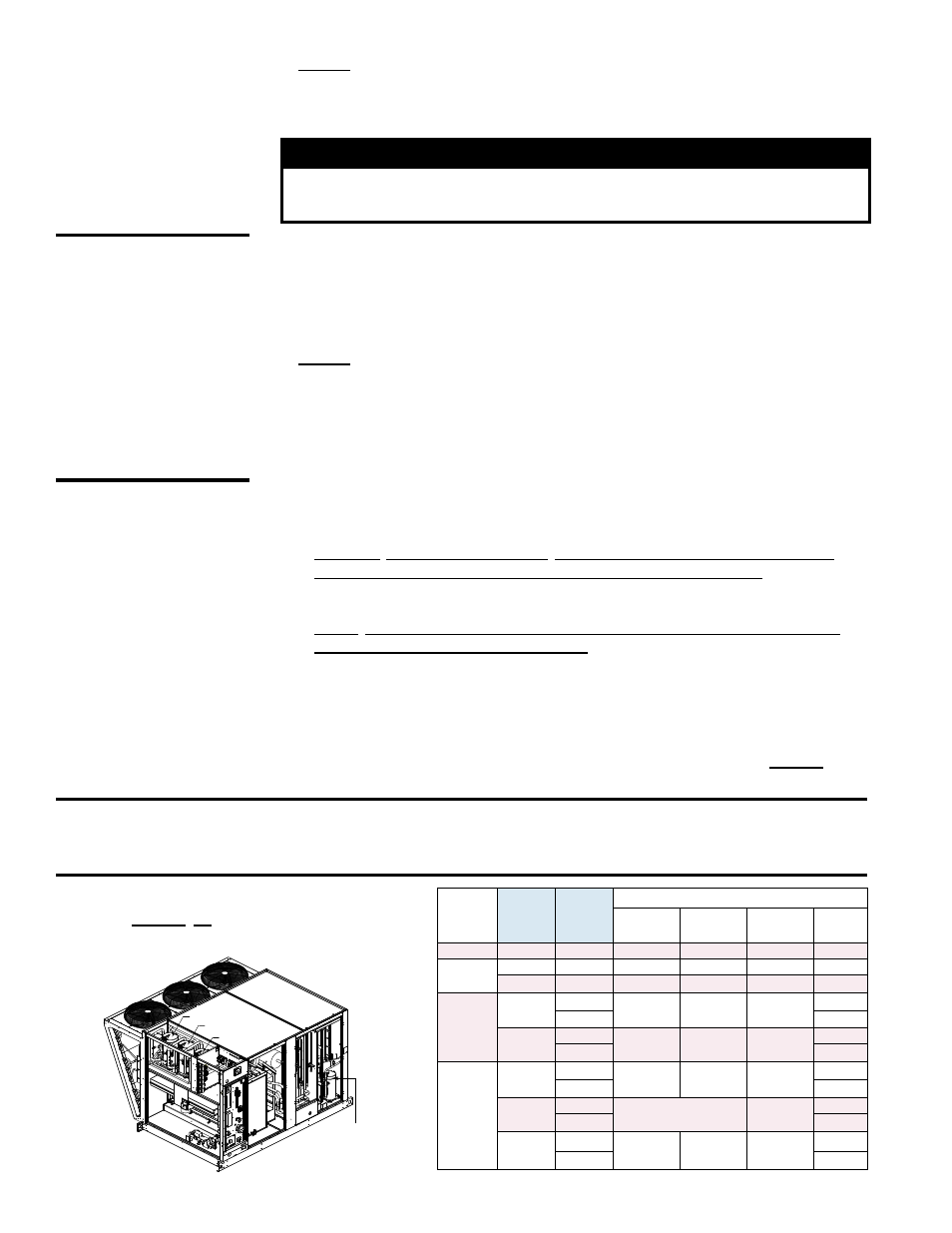

Approximate R410-A Refrigerant Charge

(lbs) for MAPS

®

IV Models by Size and

Compressor for Each Circuit

Cabinet

RCC/

RDCC/

RECC

RDC/

RDDC/

REDC

R410-A Charge (lbs) by Compressor Circuit

A

B

C

DH

(Reheat)

A

060

084

N/A

8.0

N/A

4.2

A or B

090

114

N/A

10.5

N/A

4.2

120

144

8.0

8.0

N/A

4.2

B

160

184

9.5

9.5

N/A

4.2

196

4.2

200

236

5.5

6.0

5.5

6.0

257

6.0

C

190

248

9.0

10.5

N/A

10.0

262

10.0

298

354

11.0

11.0

10.0

370

10.0

410

468

10.5

10.5

10.5

10.0

482

10.0

Compressor B

Compressor C

Compressor A

Compressor

Dh (Reheat)

3.0 Maintenance/

Service

Procedures

(cont'd)

CAUTION:

Crankcase heaters

must be allowed

to warm up for

at least 24 hours

prior to startup.

Disable cooling

controls before

turning on power

to warm up

crankcase heaters.

•

Step 9. Charge the System (Use R-410A refrigerant only.)

Refer to the applicable table (either MAPS

®

III or MAPS

®

IV) for the approximate

amount of refrigerant required. Follow the instructions below to charge the circuit.

R-410A refrigerant MUST BE charged as a LIQUID.

NOTE: Outdoor temperature must be between 70-95°F (21-35°C) for verifying

superheat and subcooling. If temperature is not within this range, consult the

factory service department before charging.

If equipped with an optional hot gas bypass, disable the hot gas bypass valve

before charging. Method of disabling depends on the model and date of

manufacture.

All MAPS

®

IV Models & any MAPS

®

III Models with a shutoff valve in the line

between the compressor discharge and the hot gas bypass valve - Locate the

shutoff valve. Disable the hot gas bypass valve by closing the shutoff valve.

When measurements are complete, be sure to open the valve.

MAPS

®

III Models without a shutoff valve in the line between the compressor

discharge and the hot gas bypass valve - Disable the hot gas bypass valve by

removing the cover and adjusting the spring tension counterclockwise until the

spring tension is relieved.

Count and record the number of turns required so

that you can return the bypass valve to its original setting. To check setting, refer

to Paragraph 3.9.5.

Liquid charge the high side to 80%. With the system running, add the balance of

the charge to the correct superheat and subcooling values. Refer to

Step 11, page

17, and the instructions in Paragraph 3.5, page 9.

IMPORTANT: Do not release refrigerant to the atmosphere! If required service

procedures include the adding or removing of refrigerant, the qualified HVAC service

technician must comply with all federal, state or provincial, and local laws.