Reznor MAPS - A,B,C Users Manual User Manual

Page 23

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 23

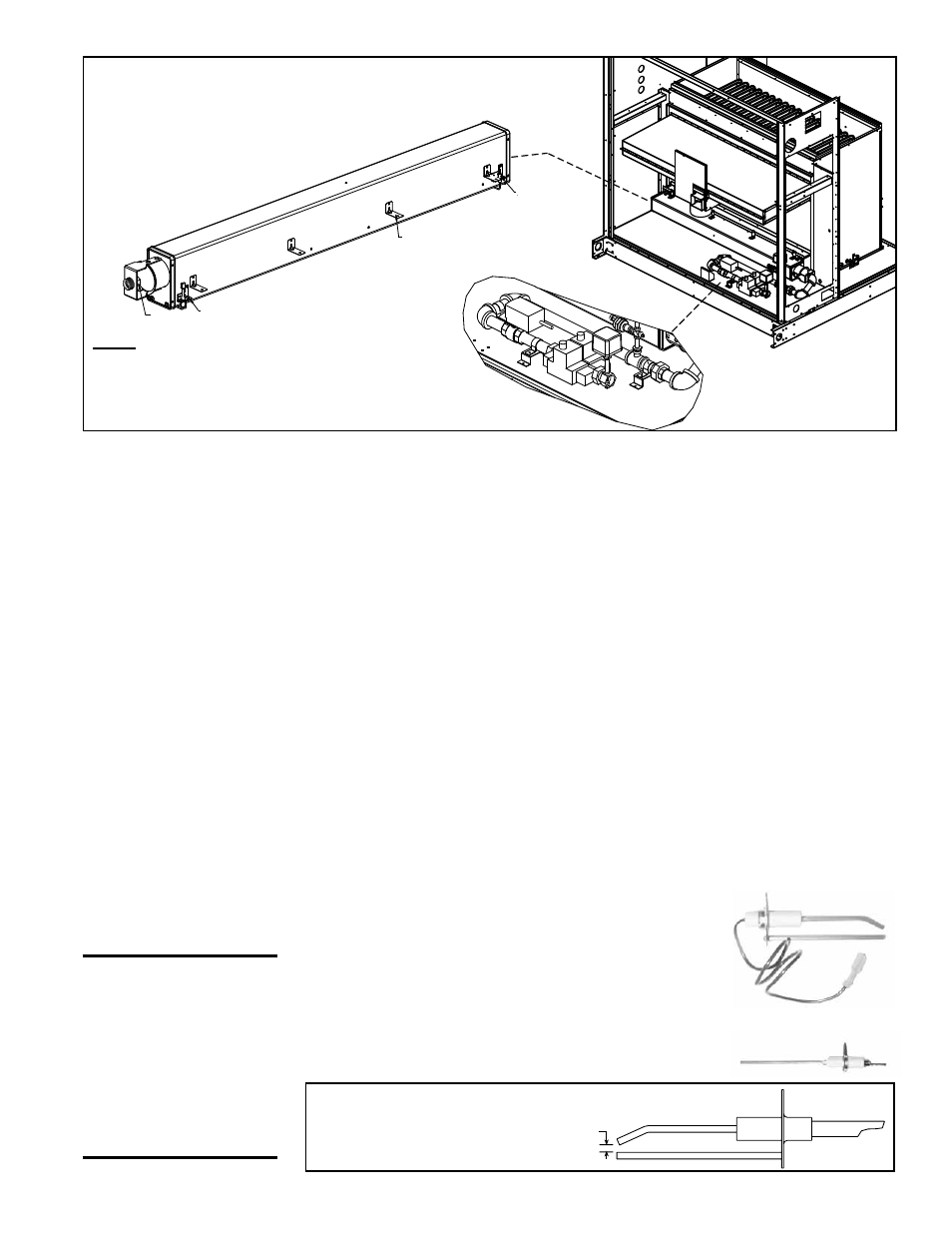

Flame

Sensor

Burner

Supports

Ignitor Assembly

Orifice

Burner Assembly

Gas Train

FIGURE 11 - Heat Section showing Burner

Assembly and Gas Train

NOTE: A "C" Cabinet heat section is illustrated.

Appearance will vary by Cabinet and size.

Maintenance requirements apply to all heat

sections including an optional curb duct furnace

(JHUP 250 or 300).

With the burner assembly removed, shine a flashlight on the burner ribbons. Look for

carbon buildup, scale, dust, lint, and/or anything that might restrict flow through the

spaces between the burner ribbons. Holding the burner assembly so that any foreign

material will fall away from the burner, use a stiff bristle brush to loosen and remove

any foreign material(s). If the burner is excessively dirty, remove both of the burner end

caps. Remove the screws that hold the end caps to the burner housing and lightly tap

end caps to remove.

Clean all foreign material from the burner and venturi. After the burner is thoroughly

cleaned, replace the end caps making certain that they are tight against the burner

housing.

Inspect and

Clean the Burner

Inspect the Lower

Portion of the Heat

Exchanger (with

burner assembly

removed)

At the burner flame entrance of each tube, shine a bright light into each heat exchanger

section. With the light shining into the heat exchanger, observe the outside for visible

light. Repeat this procedure with each heat exchanger section. If any light is observed,

replace the heat exchanger.

Burner Orifice

The burner orifice usually will not need to be replaced. If ordering a replacement orifice

only, give BTUH content and specific gravity of gas, as well as the model and serial

number of the unit and the orifice size. When removing or replacing the burner orifice

be careful not to damage the venturi tube and/or the bracket.

NOTE: If any of the

burner components

are damaged or

deteriorated, replace

the burner assembly.

Check the Ignitor and

Flame Sensor

Flame Sensor

FIGURE 12 - Ignitor

showing required Spark

Gap Measurement

1/8 inch

(3.2mm)

Ignitor - Locate the ignitor. Disconnect the wire; remove the

screw and the ignitor. Clean the ignitor assembly with an

emery cloth.

Spark gap must be maintained to 1/8". See

FIGURE 12.

IMPORTANT: When re-assembling, the brown ground wire

must remain attached to the ignitor.

Flame Sensor - Locate the flame sensor on the burner. Dis-

connect the wires; remove the screws and the flame sensor.

Clean with an emery cloth.

Ignitor

CAUTION: Due

to high voltage

on the spark wire

and electrode, do

not touch when

energized. See

Hazard Levels,

page 3.