Reznor MAPS - A,B,C Users Manual User Manual

Page 39

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 39

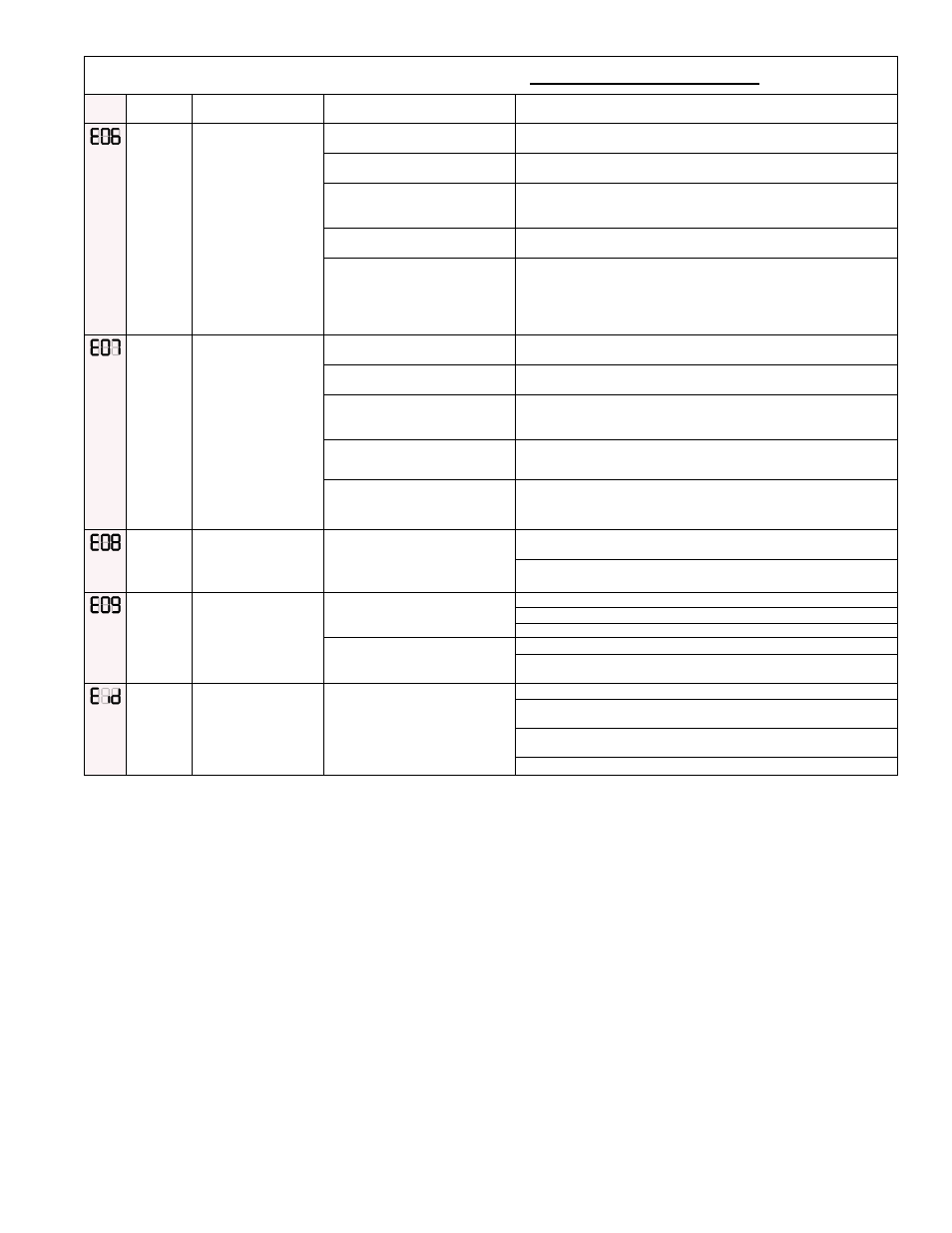

Gas Heat Section Modulating Control LOCKOUT ERRORS (cont'd)

Code

Alert

Description

Probable Causes

Solutions

Gas

Sensor

Failure

(EO6)

Pressure

Sensor

Reading

Low

The gas transducer

reading is too low

compared to the

expected value for the

modulating gas valve

actuator position.

When the furnace is

operating at 75% or

higher -- greater than

8 VDC analog input

voltage - the manifold

pressure sensor must

read 1.4" w.c. or

higher

A. Modulating actuator/ball valve

not properly aligned

1 Perform modulating system gas valve alignment procedure; see

Paragraph 4.3.

B. Line pressure too low

1. Ensure line pressure is properly adjusted for the gas and

application. Correct as needed.

C. Intermediate regulated

pressure to low

1. Ensure the safety gas valve(s) are properly adjusted to the

specified outlet pressure. Adjust per the installation instructions as

necessary.

D. Wrong gas pressure sensor

installed.

1. Ensure the proper gas transducer - either natural gas or propane

- is installed. Replace as needed.

E. Gas pressure sensor faulty

1. Ensure gas manifold transducer is installed properly and wired

per the unit wiring diagram. Replace as necessary.

Gas

Sensor

Failure

(EO7)

Pressure

Sensor

Reading

High

The gas transducer

reading is too high

compared to the

expected value for the

modulating gas valve

actuator position.

When the furnace

is operating at 75%

or lower - less than

8 VDC analog input

voltage -- the manifold

pressure sensor must

read 2.8" w.c. or lower.

A. Modulating actuator / ball

valve not properly aligned

1. Perform modulating system gas valve alignment procedure; see

Paragraph 4.3.

B. Line pressure too high

1. Ensure the line pressure is properly adjusted for the gas and

application. Correct as necessary.

C. Intermediate regulated

pressure too high

1. Ensure the safety gas valve(s) are properly adjusted to the

specified outlet pressure. Adjust per the installation instructions as

necessary.

D. Wrong gas pressure sensor

installed

1. Ensure gas sensor -- either natural or propane -- is installed.

Replace as necessary.

E. Gas pressure sensor faulty

1. Ensure gas sensor is installed properly and wired per the unit

wiring diagram. Replace as necessary.

Improper

Flame

Signal

(EO8)

Control senses flame

present when the gas

valve is commanded

off.

A. Flame remains lit in “Off” cycle 1. Gas valve leaks - check wiring to remove continuous 24V to gas

valve.

2. Gas valve is stuck open – remove, repair, or replace gas valve.

No Firing

Rate Input

(EO9)

Call for heat is sensed

(R & W closed) but

firing rate is below

defined voltage

threshold for furnace

operation.

A. Faulty wiring into the “Analog

+” and “Analog –“ terminals

1. Ensure wiring is connected per unit wiring diagram.

2. Check for loose pins or bad connections.

3. Check for frayed wiring or shorts to ground.

B. No signal from source.

1. Check firing rate input voltage – must be greater than 1.5 VDC.

2. Troubleshoot controller providing firing rate input to the deep

modulation ignition control board.

Invalid I.D.

Plug (Eid)

The installed I.D. plug

is not valid for this

control board.

A. Incorrect I.D. plug installed

1. Ensure I.D. plug is correct for the furnace – check label.

2. Ensure I.D. plug is properly inserted into the mating connector on

the control board.

3. With the I.D. plug installed, cycle power to the furnace. The board

will display the I.D. plug identity upon power-up.

4. Install correct I.D. plug as needed.