Reznor MAPS - A,B,C Users Manual User Manual

Page 37

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 37

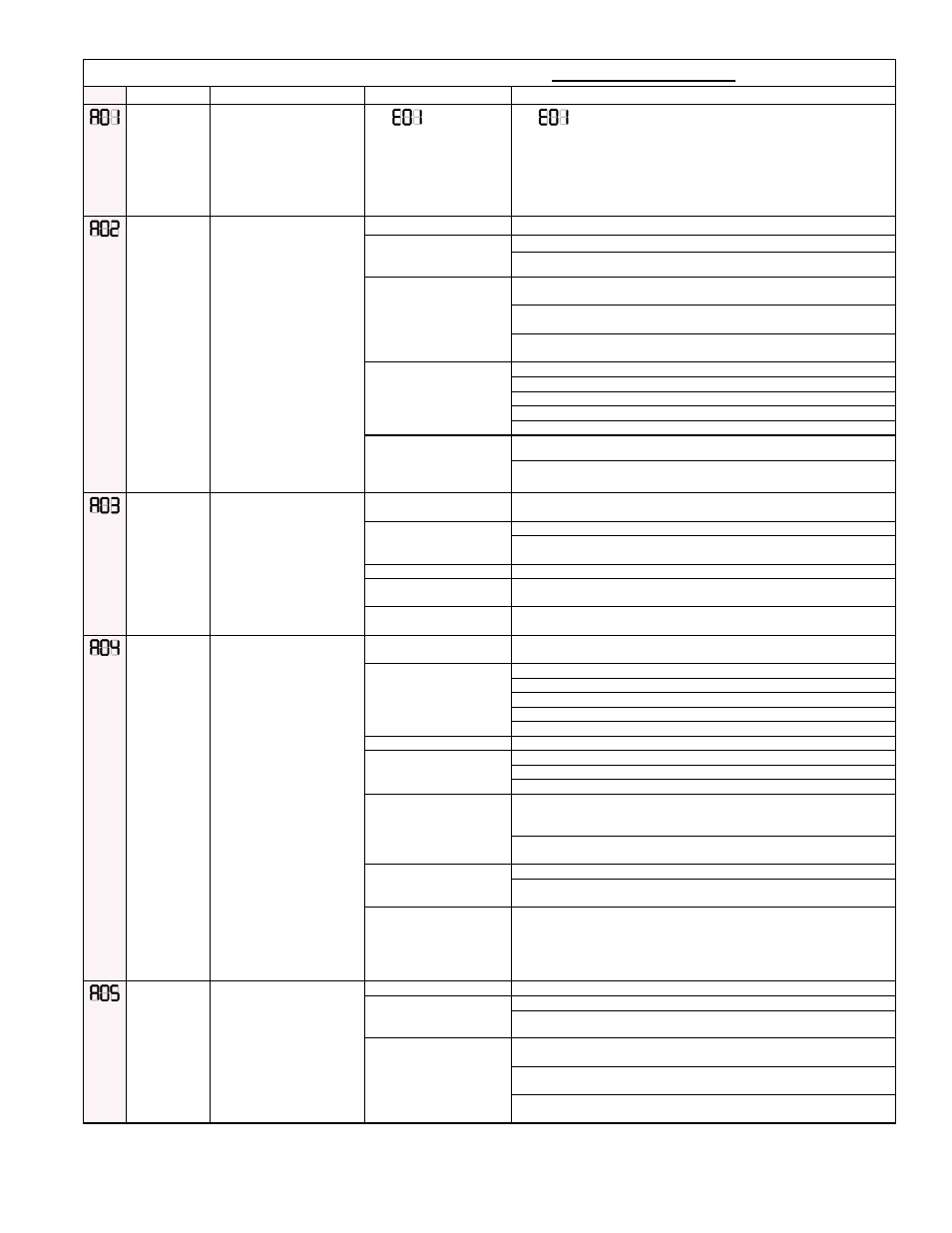

Gas Heat Section Modulating Control FUNCTIONAL ALERTS

Code

Alert

Description

Probable Causes

Solutions

Failed ignition

attempt (AO1)

Maximum

number of

allowed retries

not met

The flame could not be

established during the trial

for ignition period. This alert

indicates the maximum

number of retries has not

been exceeded and furnace

operation will continue with

another ignition attempt.

See

in the

LOCKOUT ERRORS

section, pages 38-39.

See

in the LOCKOUT ERRORS section, pages 38-39.

Lost Flame

(AO2)

The flame sensor signal

has been lost after flame is

established during a call for

heat. This alert is displayed

during the RECYCLE period

prior to the next ignition

attempt.

A. Flame sensor coated

1. Clean flame rod sensor.

B. Flame sensor

improperly mounted or

grounded

1. Check flame sensor wiring integrity and ceramic for cracks.

2. Re-install / replace flame sensor.

C. Unstable flame pattern 1. Verify that the spacing between the burner body and the burner shield

is equal across the entire length of the burner.

2. Check that the seals between the heat exchanger header and heat

exchanger tubes are sound; refer to Paragraph 4.1.1.

3. Ensure that the heat section door gasket is in place and the doors are

properly aligned

D. Insufficient intermediate

gas manifold pressure

through main gas safety

valve

1. Check for faulty gas valve wiring.

2. Check 24 VAC to gas valve assembly.

3. Check inlet pressure to safety gas valve.

4. Check outlet pressure from the safety gas valve.

5. Replace safety gas valve if faulty.

E. Insufficient gas manifold

pressure to burner through

modulating ball valve

assembly

1. Check voltage to gas valve actuator. (2-10 VDC depending on model)

2. Check alignment and set screw connection between ball valve and

actuator. See Paragraph 4.3.

Insufficient

Combustion Air

(AO3)

Furnace

functional

Furnace cannot achieve

desired combustion air flow

due to blockage or high

altitude operation resulting in

a de-rate of the furnace.

A. High altitude operation

1. Normal operation. Furnace automatically de-rates for high altitude

conditions.

B. Partially blocked vent

1 Check air inlet and outlet for blockage.

2. Check venting configuration for excessive venting length, improper

sizing, etc.

C. Leak in sensing hose

1. Check sensing hose for cracks, crimps, or loose connections.

D. Low Line Voltage

1. Check the line voltage to the control board. Voltage should be within

10% of nameplate.

E. Faulty venter assembly 1. Verify that the venter assembly is functioning properly by referring to

the sensing pressure chart on page 30.

Limited Low

Fire (AO4)

Automatic adaptive program

is currently limiting the lower

range of modulation at avoid

flame loss at minimum fire

conditions. The alert is

displayed during the run

cycle once a flame-out

condition has triggered the

Limited Low Fire function.

This function is reset by

cycling power to the board.

A. Low gas line pressure

1. Ensure gas supply is connected to furnace and check for proper line

pressure.

B. Insufficient intermediate

gas manifold pressure

through gas safety valve

1. Check for faulty gas valve wiring.

2. Check 24 VAC to gas valve assembly.

3. Check inlet pressure to safety gas valve.

4. Check outlet pressure from the safety gas valve – adjust as needed.

5. Replace safety gas valve if faulty.

C. Faulty burner operation 1. Check burner orifice for proper size and blockage.

D. Faulty flame sensor

1. Check flame rod wiring and connections.

2. Check for proper alignment of flame rod.

3. Clean flame rod sensor.

E. Improper alignment of

the modulating actuator

and the gas ball valve.

1. Check that the alignment of the actuator to the ball valve is correct.

The valve must be in the fully open position when the actuator is

energized (ACTUATOR DRIVE = 9.6 VDC or greater).

2. Ensure that the setscrew on the actuator is tightened to the ball valve

stem.

F. Blocked or improper

venting

1. Check air inlet and outlet for blockage.

2. Check venting configuration for excessive venting length, improper

sizing, etc.

G. Improper jumper

connection on IQ UI-12

causing AO-4 to show on

BacView as alarm and

disables heat sequence.

1. Verify that the IQ heating feedback input is set to receive the ignition

board voltage output of 0-10VDC from terminals J7 by making sure

jumpers are set to receive 0-10VDC signal on UI-12 of the IQ controller.

Weak Flame

Signal (AO5)

The flame signal level is

less than optimal for this

furnace. Maintenance of the

flame sensing components

is advised.

A. Flame sensor coated

1. Clean flame rod sensor.

B. Flame sensor

improperly mounted or

grounded

1. Check flame sensor wiring integrity and ceramic for cracks.

2. Re-install / replace flame sensor.

C. Unstable flame pattern 1. Verify that the spacing between the burner body and the burner shield

is equal across the entire length of the burner.

2. Check that the seals between the heat exchanger header and heat

exchanger tubes are sound; refer to Paragraph 4.1.1.

3. Ensure that the heat section door gasket is in place and the door is

properly aligned.

(continued)