0 maintenance/ service procedures (cont'd), 6 compressor maintenance (cont'd) – Reznor MAPS - A,B,C Users Manual User Manual

Page 14

Form O-MAPSIII&IV Cabinets A/B/C, Page 14

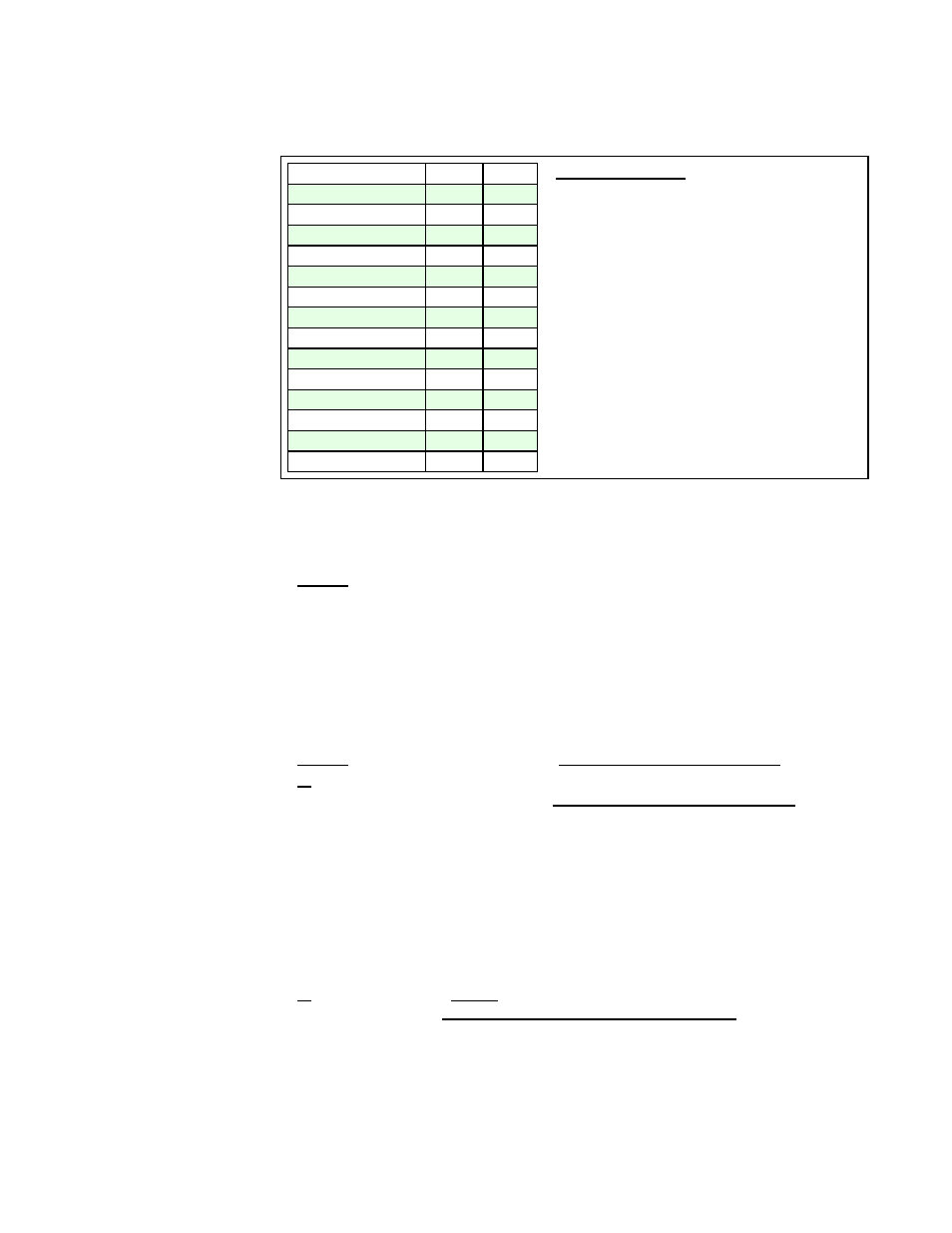

Compressor Oil Charge (POE Oil)

Compressor Model

cc

oz

ZP24K5E

621

21

ZP36K5E

1124

38

ZP54KCE

1242

42

ZP57K3E

1715

58

ZP61KCE

1538

52

ZPD61KCE

1774

60

ZP72KCE

1774

60

ZP83KCE

1656

56

ZPD83KCE

1656

56

ZP137KCE

3253

110

ZPD137KCE

3135

106

ZPT144KCE

3312

112

ZP154KCE

3253

110

ZPDT14MCE

3135

106

Important NOTES: These R-410A

compressors use a polyolester (POE)

lubricant. Types of recommended

POE

oil are Copeland Ultra 22 CC, Copeland Ultra

32 CC, Copeland Ultra 32-3MAF, Mobil EAL,

Arctic 22 CC, Uniqema Emkarate RL32CF, or

Uniqema RL32-3MAF.

POE oil absorbs moisture much quicker

and to a greater degree than standard

mineral oil. The compressor must not

be left open longer than 15 minutes

during replacement. During installation

the system must be swept with an

inert gas such as dry nitrogen to keep

moisture from entering the compressor

and prevent the formation of oxides.

4, follow procedures indicated for burnout cleanup.

Dispose of oil and compressor using an approved environmentally safe

disposal method.

•

Step 3. Mount the Replacement Compressor

Do not remove the dust cover or rubber shipping plugs until all other system

connections are complete (i.e. new liquid line filter drier(s) installed and all tubing

changes made - see Steps 4 and 5). The amount of time the compressor is open

to the atmosphere must be kept to a minimum.

Use the new mounting grommets and sleeves that are shipped with the

compressor to mount it. The sleeves will prevent over compression of the

grommets. Re-use the mounting bolts from the compressor that was removed. The

mounting bolts will bottom out when tight.

•

Step 4. Install New Filter Driers (Select procedure that applies.)

IF the oil measured in Step 2 was not significantly less than the amount shown in

the table above or the test for acid in

Step 2 did NOT indicate burnout , install

a new R-410A refrigerant liquid line filter drier. The filter drier must be rated for

no less than 600 psig and be the proper size for the circuit. Because R-410A

refrigerant requires POE oil which absorbs moisture quickly, it is important to

change the filter drier any time the circuit is opened.

It is recommended to use a tubing cutter when cutting out a filter drier as the

desiccant absorbs and holds moisture better when it is cool. Heat from a torch

may cause moisture to leave the filter and be absorbed in the oil. Be careful to

keep dirt, filings, and other contaminants out of the system.

Continue to

Step 5.

IF the oil measured in Step 2 was significantly less than shown in the table above

or the test for acid in

Step 2 did indicate compressor burnout, do the following:

a) Install a liquid line filter drier. If there is acid, install an acid removing filter

drier. Size the acid-removing filter drier at least one capacity size larger than

normally required for the circuit.

b) Install a temporary filter drier in the suction line. When there is acid, a 100%

activated alumina suction filter drier is recommended. The suction line drier

should be sized properly for the circuit and have a service access fitting to

monitor pressure drop across the drier. (NOTE: Suction line filter drier must be

removed after 72 hours of operation.)

3.0 Maintenance/

Service

Procedures

(cont'd)

3.6 Compressor

Maintenance

(cont'd)

lower than listed in the table on page 14, clean the excess oil through use

of suction and liquid line filter driers. Beginning in Step 4, follow the same

procedure as for burnout cleanup.

Use an acid test kit to check the oil for acid. If acid is found, beginning in

Step