Reznor MAPS - A,B,C Users Manual User Manual

Page 38

Form O-MAPSIII&IV Cabinets A/B/C, Page 38

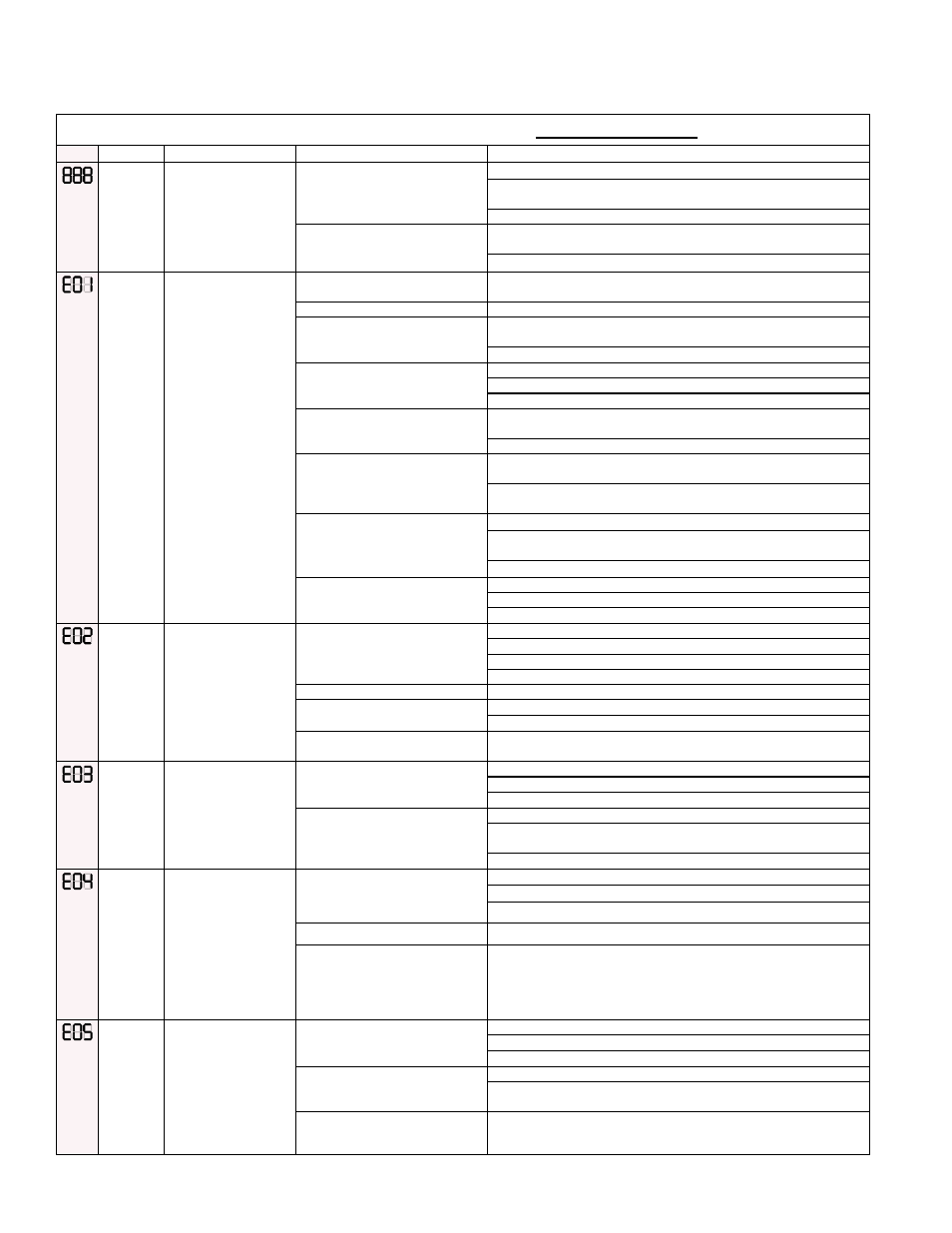

Gas Heat Section Modulating Control LOCKOUT ERRORS

Code

Alert

Description

Probable Causes

Solutions

Ignition

Board

Failure

(888)

Ignition board start-up

checks have detected

an error.

A. Faulty transformer

1. Check 24-volt transformer for correct output.

2. Check connections and wiring to control board and other

components connected to the 24 volt source.

3. Replace if necessary.

B. Faulty control board

1. Turn off power to the furnace, wait 30 seconds and turn power

back on. Re-try ignition sequence and see if the system responds.

2. Replace control board if necessary.

Failed

Ignition

(EO1)

Maximum

Retries (3)

Exceeded

The flame could

not be established

during multiple trial-

for-ignition periods

(3). The maximum

number of retries

has been exceeded

and the furnace is in

a lockout condition.

System Shutdown

alarm lockout will need

to be reset through

BacView interface or

IQ controller will need

to be power cycled.

A. Insufficient gas line pressure

1. Insure gas supply is connected to furnace and check for proper

line pressure.

B Gas valve control turned “OFF” 1. Turn gas valve to the “ON” position

C. No spark from direct spark

ignition

1. Check ignition voltage (115 VAC from board to transformer) and

wiring.

2. Check 24 VAC transformer for DSI board.

D. Insufficient intermediate gas

manifold pressure through gas

safety valve

1. Check for faulty gas valve wiring.

2. Check 24 VAC to gas valve assembly.

3. Check inlet pressure to safety gas valve.

D. (cont'd)

4. Check outlet pressure from the safety gas valve – adjust as

needed.

5. Replace safety gas valve if faulty.

E. Insufficient gas manifold

pressure to burner through

modulating ball valve assembly

1. Check voltage to gas valve actuator. (7 – 10 VDC depending on

model)

2. Check alignment and setscrew connection between ball valve and

actuator (See procedure in Paragraph 4.3.).

F. Burners do not light

1. Check spark rod assembly for proper location, spark gap, etc.

2. Verify that the spacing between the burner body and the burner

shield is equal across the entire length of the burner.

3. Check burner orifice for proper size and blockage.

G. Burners light and remain lit for

about 5 seconds

1. Check flame rod wiring and connections.

2. Check for proper alignment of flame rod.

3. Clean flame rod sensor.

Primary

Limit /

Fuse

Failure

(EO2)

The control board

safety fuse has

blown or the primary

temperature limit has

opened indicating

safe operating

temperatures for this

furnace have been

exceeded.

A. Improper circulating airflow

1. Check filter / replace if dirty.

2. Check for improperly sized duct system.

3. Check for faulty blower motor.

4. Check for faulty blower motor wiring.

B. Primary limit switch failure

1. Check for an open primary limit switch at ambient temperature.

C. Fuse is blown

1. Check and replace fuse on the board.

2. Make sure fuse socket is tight, crimp fuse terminals if necessary.

D. Faulty primary limit switch

wiring

1. Check primary limit wiring continuity from the switch to the control

board.

Modulation

Valve

Failure

(EO3)

The control lost the

position feedback from

the modulating gas

valve actuator.

A. Faulty modulation valve

actuator wiring

1. Ensure wiring is connected per unit wiring diagram.

2. Check for loose pins or bad connections.

3. Check for frayed wiring or shorts to ground.

B. Modulation valve actuator

failure

1. Ensure actuator has 24 V power.

2. Ensure actuator is receiving signal from the control board (2-10

VDC).

3. Check for actuator feedback to the control board (2-10 VDC)

Air Sensor

Failure

(EO4)

Pressure

Sensor

Reading

Low

The air sensor reading

is too low for operating

conditions or the air

pressure switch closed

when the sensor

indicates low flow

The pressure switch

MUST be open prior to

venter activation.

A. Faulty wiring or connections

1. Check pressure switch wiring.

2. Check inducer wiring.

3. Check for plugged or disconnected vacuum hoses.

B. Faulty pressure switch

1. Replace pressure switch.

C. Faulty pressure sensor,

located on the board

1. Replace board.

Air Sensor

Failure

(EO5)

Pressure

Sensor

Reading

High

The air sensor reading

is too high when the

venter is off or the

air pressure switch

open when the sensor

indicates high flow.

The pressure switch

MUST close to initiate

an ignition sequence.

A. Faulty wiring or hose

connections

1. Check pressure switch wiring.

2. Check venter motor wiring.

3. Check for broken or disconnected vacuum hoses.

B. Blocked or improper venting

1. Check air inlet and outlet for blockage.

2. Check venting configuration for excessive venting length,

improper sizing, etc.

C. Faulty pressure switch

1. Replace pressure switch.

7.3 Troubleshooting the Heat Section (cont'd)

7.3.3 Modulating Control Module on Cabinet A, B, C Gas Heat Sections (cont'd)