0 maintenance and service procedures (cont'd) – Reznor MAPS - A,B,C Users Manual User Manual

Page 10

Form O-MAPSIII&IV Cabinets A/B/C, Page 10

R-410A Refrigerant

R-410A Refrigerant

R-410A Refrigerant

R-410A Refrigerant

R-410A Refrigerant

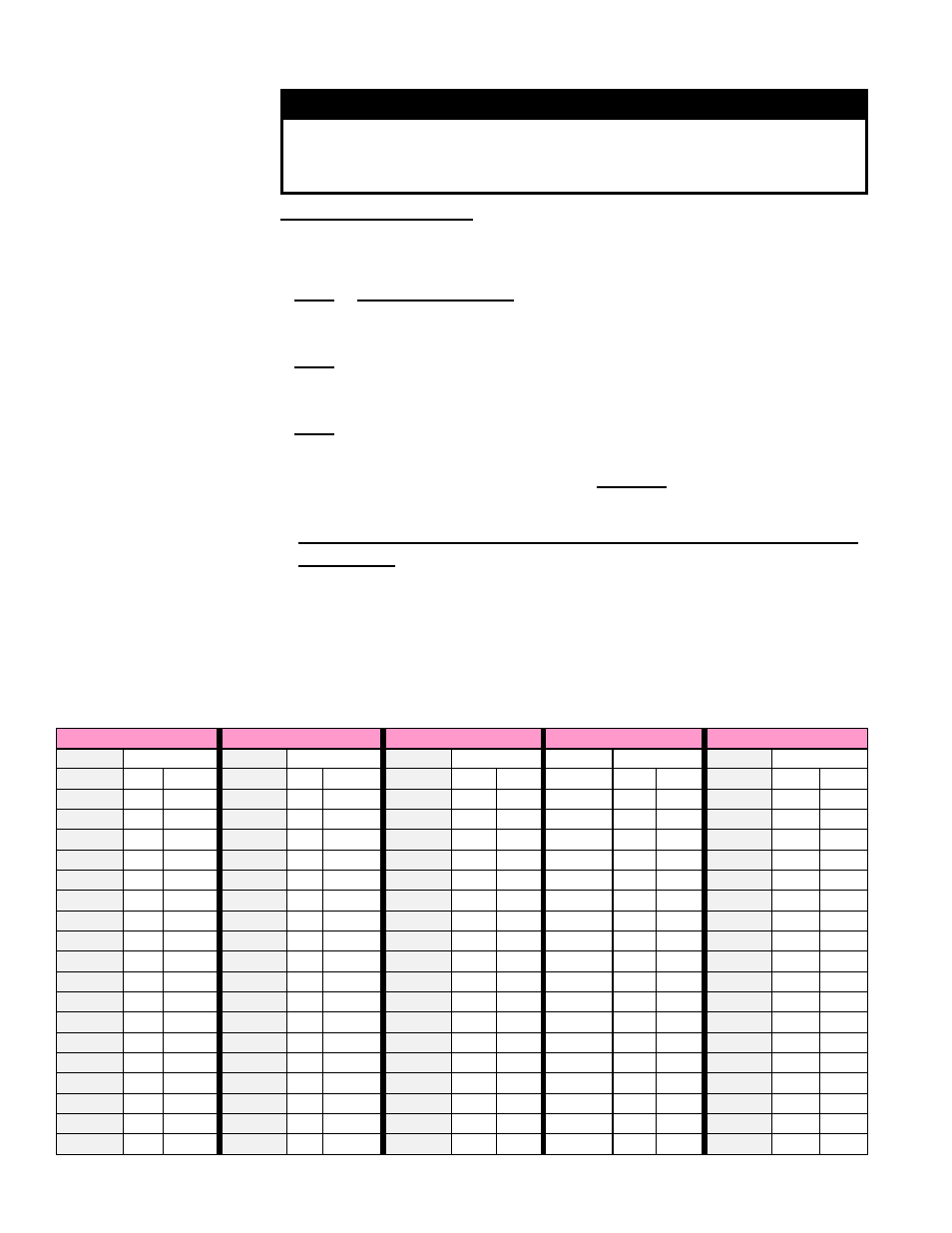

Pressure Temperature

Pressure Temperature

Pressure Temperature

Pressure Temperature Pressure Temperature

PSI

°F

°C

PSI

°F

°C

PSI

°F

°C

PSI

°F

°C

PSI

°F

°C

1.8

-55 -48.3

49.5

1

-17.2

77.0

19

-7.2

112.2

37

2.8

218.2

75

23.9

4.3

-50 -45.6

50.9

2

-16.7

78.7

20

-6.7

114.4

38

3.3

235.9

80

26.7

7.0

-45 -42.8

52.2

3

-16.1

80.5

21

-6.1

116.7

39

3.9

254.6

85

29.4

10.1

-40 -40.0

53.6

4

-15.6

82.3

22

-5.6

118.9

40

4.4

274.3

90

32.2

13.5

-35 -37.2

55.0

5

-15.0

84.1

23

-5.0

121.2

41

5.0

295.0

95

35.0

17.2

-30 -34.4

56.4

6

-14.4

85.9

24

-4.4

123.6

42

5.6

316.9

100 37.8

21.4

-25 -31.7

57.9

7

-13.9

87.8

25

-3.9

125.9

43

6.1

339.9

105 40.6

25.9

-20 -28.9

59.3

8

-13.3

89.7

26

-3.3

128.3

44

6.7

364.1

110 43.3

27.8

-18 -27.8

60.8

9

-12.8

91.6

27

-2.8

130.7

45

7.2

389.6

115 46.1

29.7

-16 -26.7

62.3

10 -12.2

93.5

28

-2.2

133.2

46

7.8

416.4

120 48.9

31.8

-14 -25.6

63.9

11

-11.7

95.5

29

-1.7

135.6

47

8.3

444.5

125 51.7

33.9

-12 -24.4

65.4

12

-11.1

97.5

30

-1.1

138.2

48

8.9

474.0

130 54.4

36.1

-10 -23.3

67.0

13 -10.6

99.5

31

-0.6

140.7

49

9.4

505.0

135 57.2

38.4

-8

-22.2

68.6

14 -10.0

101.6

32

0.0

143.3

50

10.0

537.6

140 60.0

40.7

-6

-21.1

70.2

15

-9.4

103.6

33

0.6

156.6

55

12.8

571.7

145 62.8

43.1

-4

-20.0

71.9

16

-8.9

105.7

34

1.1

170.7

60

15.6

607.6

150 65.6

45.6

-2

-18.9

73.5

17

-8.3

107.9

35

1.7

185.7

65

18.3

645.2

155 68.3

48.2

0

-17.8

75.2

18

-7.8

110.0

36

2.2

201.5

70

21.1

3.0 Maintenance and Service Procedures (cont'd)

3.5 Check

Refrigerant

Pressure and

Temperatures

(cont'd)

Temperature/Pressure Conversion Chart

WARNING

Do not release refrigerant to the atmosphere. When adding or

removing refrigerant, the qualified technician must comply

with all national, state/province, and local laws.

Determine SUPERHEAT

Measure and record temperature (insulate probe from surrounding air temperature)

and pressure in the suction line at the compressor inlet.

STEP 1) Record Measurements: Temperature = _______°F (°C) and

Pressure = _______ psig

STEP 2) From Temperature/Pressure Conversion Chart (below), convert

Measured Pressure (STEP 1) to ________°F (°C)

STEP 3) Subtract Measured Temperature (STEP 1) from Temperature from

Conversion Table (STEP 2)

________°F (°C) - ________°F (°C) = ________°F (°C) degrees of

Superheat

Recommended superheat range is 8 to 12 degrees F (4.5 to 6.7

degrees C).

Typically, too much superheat indicates that the evaporator coil is undercharged.

Too little superheat typically indicates that the evaporator coil is overcharged and

may potentially flood liquid refrigerant to the compressor. To reduce the superheat,

adjust the thermal expansion valve by turning the adjusting stem counterclock-

wise. To increase the superheat, adjust the thermal expansion valve by turning the

adjusting stem clockwise.