3 gas train (cont'd) – Reznor MAPS - A,B,C Users Manual User Manual

Page 28

Form O-MAPSIII&IV Cabinets A/B/C, Page 28

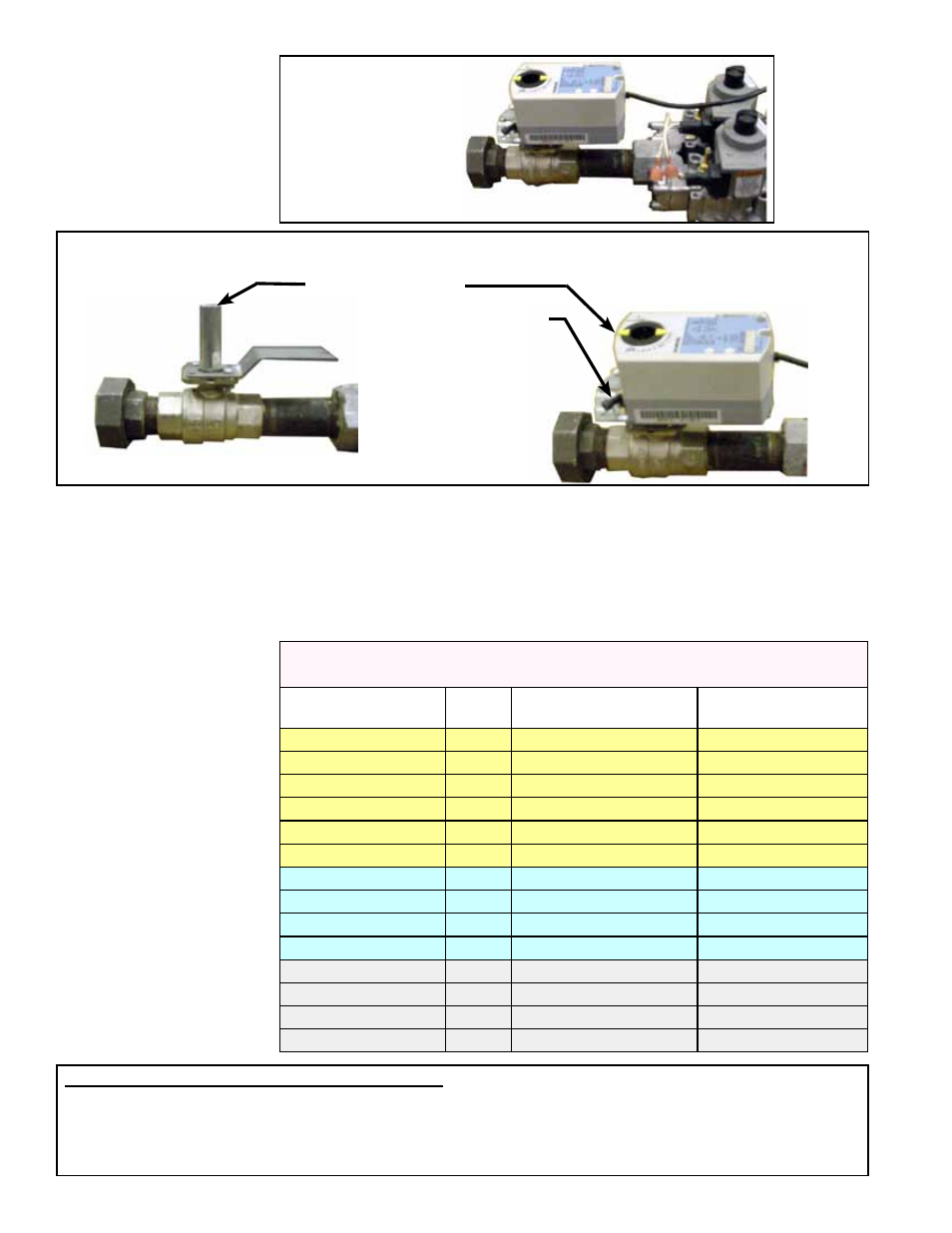

Ball Valve with actuator removed

Ball Valve Actuator

Modulates the Gas Flow

Actuator

Set Screw

(shown on the

right or closed

position)

Ball Valve Shaft

FIGURE 17B - Ball Valve with Actuator in Modulating Gas Control (Option AG70) Manifold

Modulating System

Gas Valve (Ball

Valve and Actuator)

Adjustment

4.3 Gas Train

(cont'd)

Inspect the position of the ball valve shaft.

□

In the fully open position, the dash marks on the top of the shaft should be aligned

with the gas piping.

□

In the fully closed position, the dash marks on the top of the shaft should be

aligned at a 90° angle across the gas piping.

If the ball valve shaft is not properly aligned or if the manifold pressure does not match

the settings in the chart below, the ball valve will need to be adjusted.

FIGURE 17A -

Ball Valve and

Actuator in Gas

Control Option

AG70

Manifold Pressures

for MAPS

®

III&IV Gas

Modulation System

Manifold Pressure (" w.c.) Measured

at the Pressure Tap by the Gas Transducer

Cabinet and Heat

Section Size

Gas

Type

High Setting

100% on ModHeat

Low Setting

0% on ModHeat

A-Cab 100

Nat

3.4" w.c.

0.15" w.c.

A-Cab 150

Nat

3.4" w.c.

0.15" w.c.

A-Cab 200

Nat

3.4" w.c.

0.15" w.c.

A-Cab 100

LP

10.0" w.c.

0.5" w.c.

A-Cab 150

LP

10.0" w.c.

0.5" w.c.

A-Cab 200

LP

10.0" w.c.

0.5" w.c.

B-Cab 250

Nat

3.4" w.c.

0.15" w.c.

B-Cab 300

Nat

3.4" w.c.

0.15" w.c.

B-Cab 250

LP

10.0" w.c.

0.45" w.c.

B-Cab 300

LP

10.0" w.c.

0.45" w.c.

C-Cab 400

Nat

3.4" w.c.

0.2" w.c.

C-Cab 500

Nat

3.4" w.c.

0.2" w.c.

C-Cab 600

Nat

3.4" w.c.

0.2" w.c.

C-Cab 700

Nat

3.4" w.c.

0.2" w.c.

To adjust gas modulation follow instructions below:

1. Checking modulation requires a manometer capable of reading to 0.10" w.c. Connect the manometer as

instructed in Step 1.f) below.

To check and adjust the modulation system, the IQ controller must be in

Test Mode. On the control display in the

electrical compartment, follow the steps below to enter

Test Mode.

4.0 Gas Heat

Section

Maintenance

(cont'd)