0 general – Reznor MAPS - A,B,C Users Manual User Manual

Page 2

Form O-MAPSIII&IV Cabinets A/B/C, Page 2

1.0 General

This booklet includes operation, maintenance, and service information for Cabinet

Sizes A, B, and C of the MAPS

®

III and MAPS

®

IV Models listed below. Before begin-

ning any procedure, carefully review the information, paying particular attention to the

warnings. Handling of refrigerant should only be performed by a certified HVAC techni-

cian with knowledge of the requirements of R-410A refrigerant and in compliance with

all codes and requirements of authorities having jurisdiction.

The instructions in this manual apply to the following MAPS

®

Models in Cabinet A, B,

and C Sizes and Model JHUP 250 and 300 duct furnace curb option.

1.0 General ....................................................2-3

2.0 Maintenance Requirements ..................3-6

2.1 Maintenance Schedule.....................................4

2.2 Control Locations .............................................5

2.3 Cross-Reference of Models and

Cabinet Sizes A, B, and C ..............................6

3.0 Maintenance & Service Procedures ...6-21

3.1 Filters ..............................................................6

3.2 Drive Components ...........................................7

3.3 Condenser Fans...............................................8

3.4 Coil Maintenance .............................................8

3.5 Check Refrigerant Pressure & Temperatures

(subcooling and superheat) .............................9

3.6 Compressor Operation, Maintenance, and

Replacement.................................................. 11

3.7 Thermostatic Expansion Valves .....................19

3.9 Other Controls ................................................20

3.8 Optional Dampers and Damper Controls .......20

4.0 Gas Heat Section Maintenance -

RDCB, RDCC, RDDB, RDDC .............21-30

4.1 Heat Exchanger, Burner, and Venter..............21

4.2 Heat Section Controls ....................................25

4.3 Gas Train........................................................26

4.4 Other Gas Heat Section Controls / Sensors ..30

5.0 Electric Heat Section Maintenance -

RECB, RECC, REDB, REDC ..............30-31

Option ER1 ..............................................31

7.0 Troubleshooting .................................32-39

7.1 Troubleshooting - Refrigeration (All Models) ..32

7.2 Compressor Digital Controller

7.3 Troubleshooting the Heat Section .................34

INDEX .............................................................40

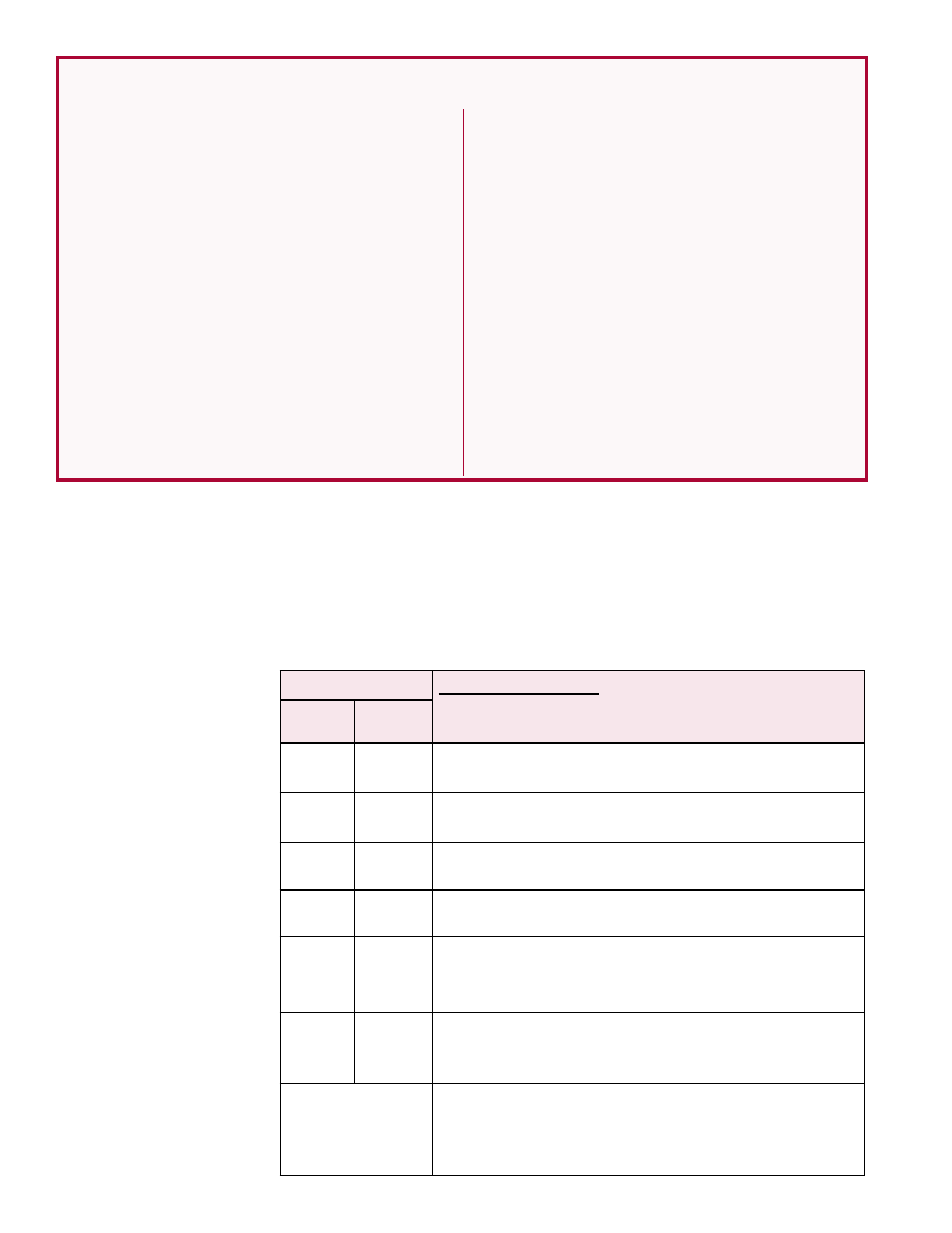

Table of Contents

Model

System Description (MAPS

®

III models have

staged cooling; MAPS

®

IV models have modulating

cooling.)

MAPS

®

III MAPS

®

IV

RCB

RCC

Makeup Air Cooling Packaged System, 1500-9000

CFM

RDCB RDCC Makeup Air Cooling Packaged System, 1500-9000

CFM, with Gas Heat Section (100-700 MBH)

RECB

RECC Makeup Air Cooling Packaged System, 1500-9000

CFM, with Electric Heat Section (10- 88 kw)

RDB

RDC

Makeup Air Cooling and Re-heat Pump Reheat Cycle

Packaged System, 1500-9000 CFM

RDDB

RDDC

Makeup Air Cooling and Re-heat Pump Reheat Cycle

Packaged System, 1500-9000 CFM, with a Gas Heat

Section (100-700 MBH)

REDB

REDC

Makeup Air Cooling and Re-heat Pump Reheat Cycle

Packaged System, 1500-9000 CFM, with Electric Heat

Section (10 - 88 kw)

JHUP

Optional Curb Section with 250 or 300 MBH Gas-Fired

Duct Furnace installed with a Model RDCB, RDCC,

RDDB or RDDC with a Size 250 or 700 Heat Section to

provide 500 or 1000 MBH heating

NOTE: To confirm that this

booklet is applicable, see

list of Model and Cabinet

Sizes in Paragraph 2.3,

page 6.