Ad b c, 4 coil maintenance, Ab d c – Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 7: Condenser coil cleaning instructions, Evaporator coil cleaning instructions

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 7

3.4 Coil

Maintenance

Inspect all cooling system coils at the beginning of the cooling season or more often if

needed. Follow the cleaning instructions below. If additional cleaning is required or if a

coil must be removed for any reason, consult the factory. Be prepared to provide rating

plate and installation information.

Condenser Coil Access - The bank of condensing coils is located on top of the unit.

Condenser Coil Cleaning Instructions:

1) Verify that the electrical power has been turned off and the disconnect switch

locked.

2) Use a soft brush to remove any dirt and debris from the coils.

3) Spray with cold or warm (not hot) water and a cleaning solution (non-acid based

coil cleaner is recommended). Due to possible damage to the coil,

do not use

high pressure spray.

4) When clean, rinse with cool, clean water.

Evaporator Coil Access - The evaporative coils can be accessed by opening the coil

cabinet door.

Inspect coils for debris, dirt, grease, lint, pollen, mold, or any element which would

obstruct heat transfer or airflow. Inspect coils and tubing for physical damage. Inspect

feeders, piping connections, coil headers, and return bends for signs of fatigue, rub-

bing, and physical damage.

Clean the coils annually, or more often if needed. Use the proper tools and follow the

instructions carefully to avoid damaging the coil. Use of a non-acid based coil cleaner

is recommended. Due to possible damage to the coil, high pressure spray is not rec-

ommended.

Evaporator Coil Cleaning Instructions:

1) Verify that the electrical power has been turned off and the disconnect switch

locked.

2) Open the access panels.

3) Use a soft brush to remove any dirt and debris from both sides of a coil.

4) Spray with cold or warm (not hot) water and a cleaning solution (non-acid based

coil cleaner is recommended). Due to possible damage to the coil, high pressure

spray is

not recommended. First spray the leaving airflow side, then the inlet

airflow side.

As much as possible, spray the solution perpendicular to the face of the coil.

Follow the instructions on the cleaning solution. When cleaning process is

complete, rinse both sides with cool, clean water.

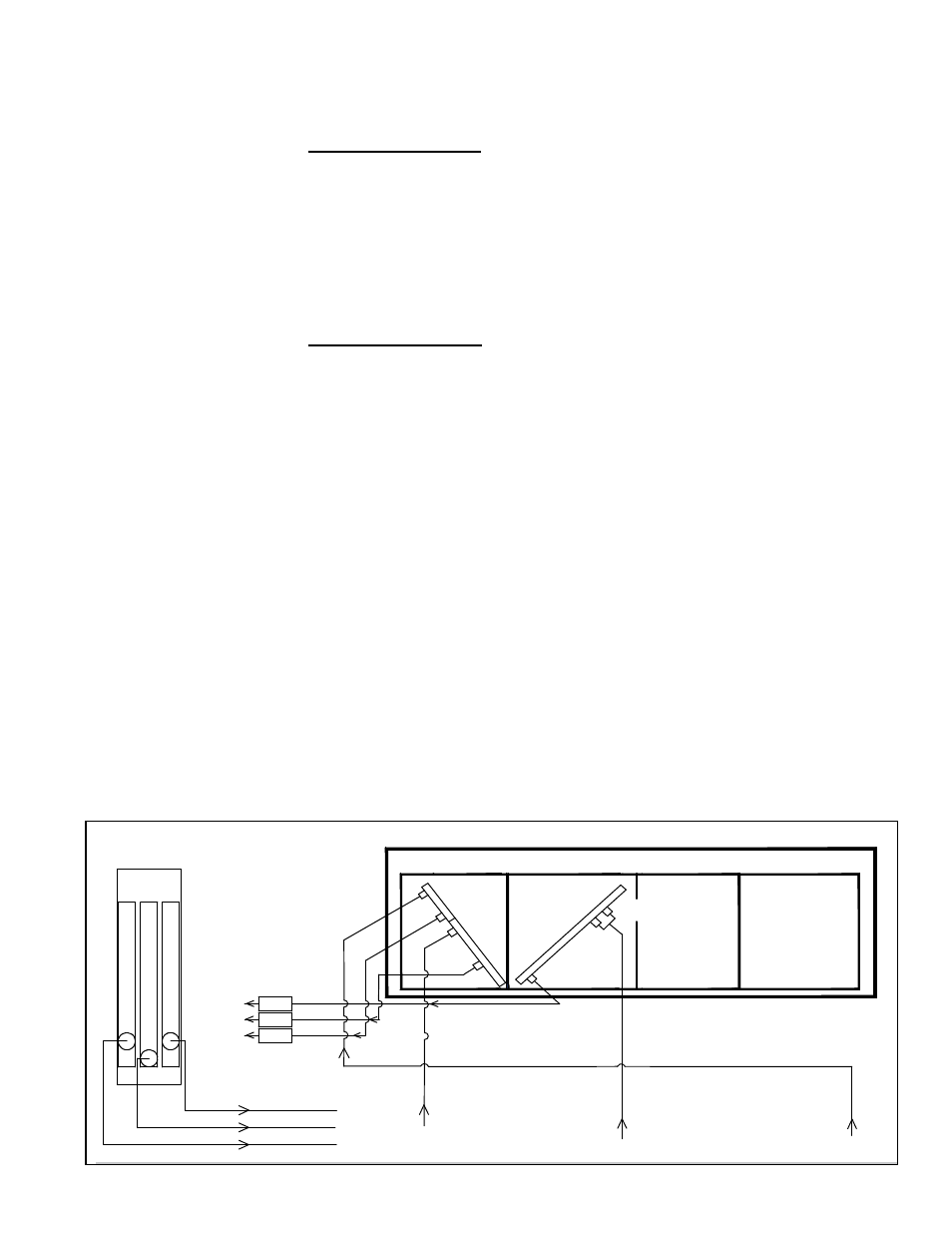

FIGURE 4 - Coil Circuits (Views are from the control side of the system.)

Condenser Coils by Circuit

Condenser Coils by Circuit

A

D

A

B C

D

A

B

C

10 ton MC Coil

5 ton MC Coil

10 ton MC Coil

15 ton MC Coil

15 ton MC Coil

Inlet 1

Ø 0.881

Inlet 1

Ø 0.879

Inlet

Ø 0.881

Inlet 2

Ø 0.881

Inlet 2

Ø 0.879

Inlet 1

Ø 0.881

Inlet 2

Ø 0.881

Outlet

Ø 0.881

Outlet

Ø 0.881

Outlet

Ø 0.879

Outlet

Ø 0.881

Discharge Line Ø 0.875

Discharge Line Ø 0.875

Discharge Line Ø 0.875

Discharge Line Ø 0.500

Discharge Line Ø 0.875

Discharge Line Ø 0.875

Liquid Line Ø 0.875

Liquid Line

Ø 0.875

Liquid Line

Ø 0.875

Liquid Line

Ø 0.875

Liquid Line

Ø 0.500

Liquid Line Ø 0.875

Filter Drier

Filter Drier

Filter Drier

Filter Drier

Filter Drier

Filter Drier

A

D

B

C

Discharge Line Ø 0.875

Discharge Line Ø 0.875

Discharge Line Ø 0.875

Discharge Line Ø 0.875

Liquid Line

Ø 0.875

Liquid Line

Ø 0.875

Liquid Line Ø 0.875

Liquid Line Ø 0.875

Filter Drier

Filter Drier

Filter Drier

Filter Drier

Outlet

Ø 0.881

Outlet

Ø 0.881

Outlet

Ø 0.881

Outlet

Ø 0.881

Inlet

Ø 0.881

Inlet 2

Ø 0.881

Inlet 1

Ø 0.881

Inlet 2

Ø 0.881

Inlet 1

Ø 0.881

Inlet

Ø 0.881

10 ton MC Coil

10 ton MC Coil

15 ton MC Coil

15 ton MC Coil

(See compressor locations on page 12.)

(See compressor locations on page 12.)

(See compressor

locations on page 12.)

Evaporator Coils by

Circuit (interlaced)

Evaporator Coils by

Circuit (interlaced)

A

C

D

A

C

D

A

C

D

All three

outlets

Ø 1.380

All four

outlets

Ø 1.380

Suction Line Ø 1.375

Suction Line Ø 1.375

Suction Line Ø 0.875

Suction Line Ø 1.375

Suction Line Ø 1.375

Suction Line Ø 1.375

RCB/RDCB/RECB 480 and

RDB/RDDB/REDB 538, 564, and 602

RCB/RDCB/RECB 360 and

RDB/RDDB/REDB 418, 444, and 484

RCB/RDCB/RECB 600 and

RDB/RDDB/REDB 658, 684, and 722

A

B D

C

Suction Line Ø 1.375

Suction Line Ø 1.375

Suction Line Ø 1.375

Suction Line Ø 1.375

(T

o TXV valves and Distributors on Evaporator Coils)

(T

o TXV valves and Distributors on Evaporator Coils)

(T

o TXV valves and Distributors

on Evaporator Coils)

Condenser Coils by Circuit

15 ton MC Coil

Inlet

Ø 0.506

Outlet Ø 0.506

Inlet

Ø 0.879

Outlet Ø 0.879

Outlet Ø1.380

Outlet Ø1.380

Outlet Ш 0.879