0 maintenance procedures (cont'd), 9 other controls (cont'd), 5 hot gas bypass valve, option auc9 – Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 20: 4 voltage protection, option pl4, Bypass valve 3.9.2 air proving switch

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 20

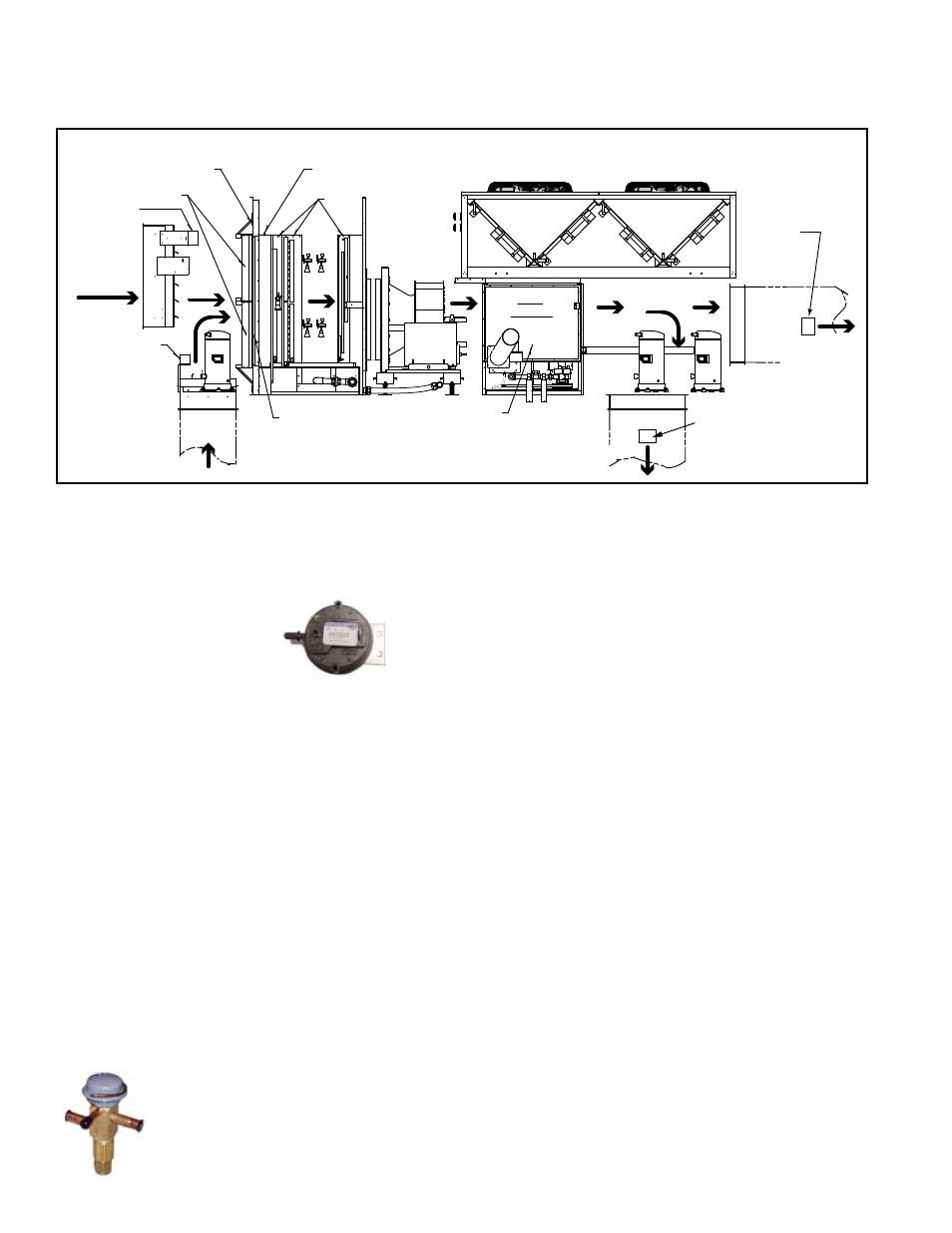

Outside

Air

Return

Air

Mixed Air Averaging

Sensor (between

filters and coil)

Return Air

Sensor

Temperature/

Humidity

Outside

Air Sensor

Temperature/

Humidity

Filters

Dirty Filter Switch Sensor

(entering air side)

Dirty Filter Switch Sensor

(leaving air side)

Coils

Air Proving

Switch Tap

Heat

Section

Discharge Temperature

Sensor (field installed)

Discharge

Temperature

Sensor (field

installed)

Vertical

Discharge

Horizontal

Discharge

Condenser Section

FIGURE 6 - Airflow and Sensor Locations

3.9.3 Motor Starter

(Option AN10) or

Variable Frequency

Drive (Option VFD1 or

VFD2)

Function: The hot gas bypass valve allows some of the refrigerant gas from the suc-

tion line to be re-routed directly to the evaporator coil providing for expanded compres-

sor modulation at low outside air temperatures.

Service: To check the hot gas bypass valve setting, connect a pressure gauge to the

suction line and block the entering air to the evaporator coil. Suction pressure will drop,

and the hot gas bypass valve should begin to open at a approximately 115 psi and will

be fully open at 95 psi. When the valve begins to open it will be hot to the touch (see

caution below).

3.9.5 Hot Gas Bypass

Valve, Option AUC9

3.0 Maintenance Procedures (cont'd)

3.9.4 Voltage

Protection,

Option PL4

Function: Phase loss and low or high voltage can cause damage to electrical com-

ponents. This safety control monitors phase loss and voltage and shuts down the unit

when its limits are exceeded. The device is auto reset and allows the unit to restart

when the power conditions are corrected.

Bypass

valve

3.9.2 Air Proving

Switch

Service: If a sensor needs to be replaced, use only a factory authorized replacement

part designed for the purpose. Refer to the digital wiring requirements in Paragraph 7.4

of Installation Form I-MAPSIII&IV).

If a controller needs to be replaced, it must be replaced with the same controller and

software.

Function: The airflow proving switch is a pressure switch that veri-

fies to the main controller that the blower (plenum fan) is operating.

Service: If the switch needs to be replaced, use a factory-authorized

replacement designed for the application.

Function: When the main controller calls for blower operation, either an IEC type

starter with a contactor or a variable frequency drive module responds to operate the

motor.

The starter is in the high voltage control compartment. The variable frequency drive

was field installed in a location that is no more than 50 feet (15M) away where the

minimum temperature is 18°F (-9°C). Control of the variable frequency drive module is

coordinated with the main controller, and depending on what was ordered, can function

in response to temperature, CO2, or pressure controls.

Service: If a starter or contactor need replaced, use only the identical replacement that

is designed to match the motor and voltage of the system.

If a VFD needs to be replaced, contact the factory service department. Be prepared to

provide the model, serial, and wiring diagram numbers.

3.9.1 Programmable Digital Controller and Sensors (cont'd)

3.9 Other Controls (cont'd)