0 maintenance/ service procedures (cont'd), 6 compressor maintenance (cont'd) – Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 12

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 12

Compressor Oil Charge (POE Oil)

□

Step 3. Mount the Replacement Compressor

Do not remove the dust cover or rubber shipping plugs until all other system

connections are complete (i.e. new liquid line filter drier(s) installed and all tubing

changes made - see Steps 4 and 5). The amount of time the compressor is open

to the atmosphere must be kept to a minimum.

Use the new mounting grommets and sleeves that are shipped with the

compressor to mount it. The sleeves will prevent over compression of the

grommets. Re-use the mounting bolts from the compressor that was removed. The

mounting bolts will bottom out when tight.

If the oil taken from the compressor and measured is found to be significantly

lower than listed in

the table above, clean the excess oil through use of suction

and liquid line filter driers.

Beginning in Step 4, follow the same procedure

as for burnout cleanup.

Use an acid test kit to check the oil for acid.

If acid is found, beginning in

Step 4, follow procedures indicated for burnout cleanup.

Dispose of oil and compressor using an approved environmentally safe

disposal method.

Compressor

Model

cc

oz

ZP57K3E

1538

52

ZP83KCE

1656

56

ZP120KCE

3135 106

ZP182KCE

3135 106

3.0 Maintenance/

Service

Procedures

(cont'd)

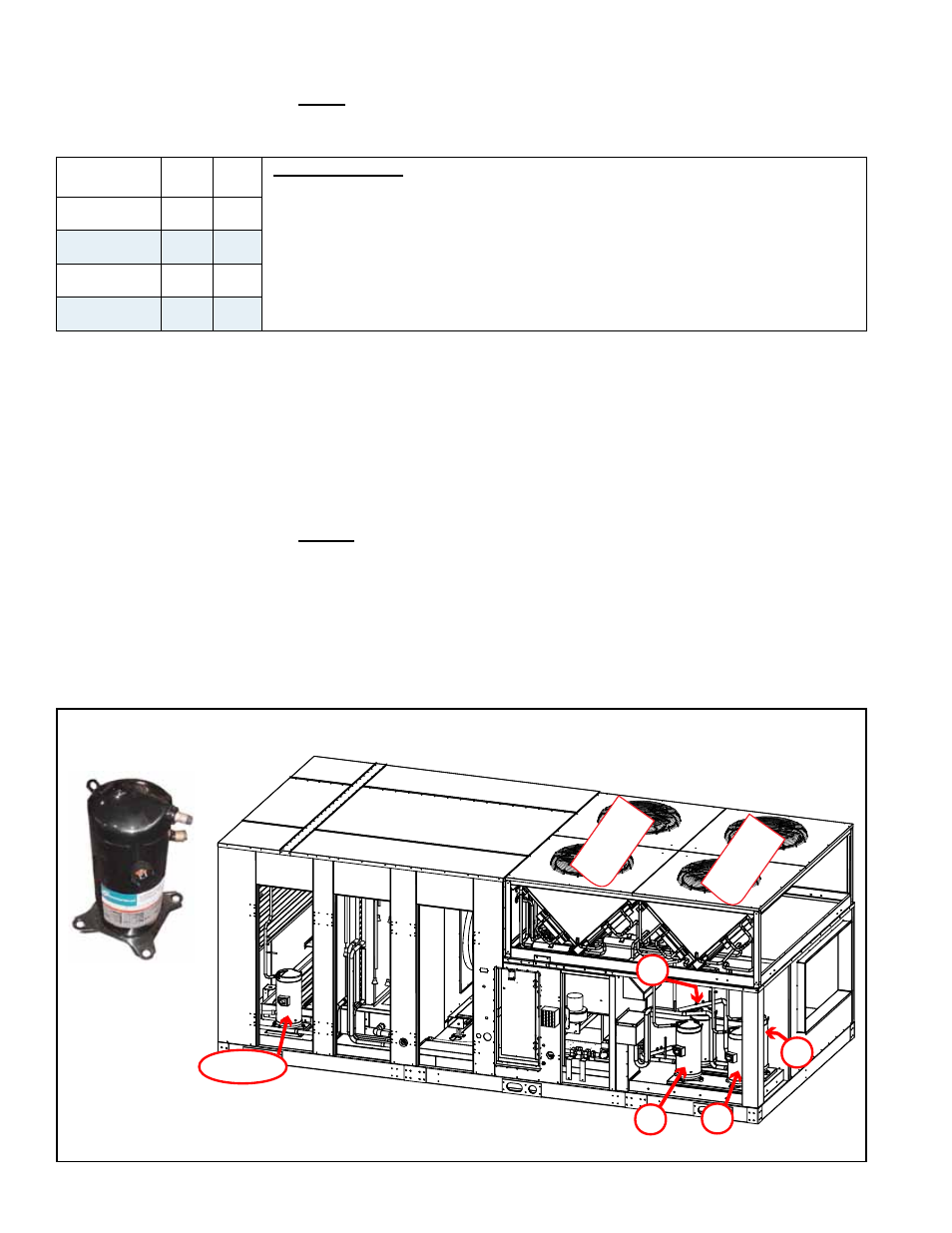

3.6 Compressor Maintenance (cont'd)

Compressor

FIGURE 5 - Identification of Compressors by Location

Reheat compressor in

Models RDB and RDDB

A

C

B

DH or E

D

Condenser

Bank B & C

Condenser

Bank

A & D

Step 2. Determine Cause of Initial Failure (cont'd)

Important NOTES: These R-410A compressors use a polyolester (POE)

lubricant. Types of recommended

POE oil are Copeland Ultra 22 CC, Copeland Ultra

32 CC, Copeland Ultra 32-3MAF, Mobil EAL™, Arctic 22 CC, Uniqema Emkarate RL32CF,

or Uniqema RL32-3MAF.

POE oil absorbs moisture much quicker and to a greater degree than standard

mineral oil. The compressor must not be left open longer than 15 minutes

during replacement. During installation the system must be swept with an inert

gas such as dry nitrogen to keep moisture from entering the compressor and

prevent the formation of oxides.