Maintenance/ service procedures (cont'd), 6 compressor maintenance (cont'd) – Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 16

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 16

□

Step 10. System Startup

Assure voltage to compressor does not drop below minimum allowable voltage

(e.g. 187 volts for 230/208-3-60, 415 volts for 460/3/60, 518 volts for 575/3/60)

during the period the compressor is trying to start.

If a low voltage or voltage

imbalance condition exists, the electrical problem must be determined and

corrected prior to operating the unit.

Voltage Imbalance - Voltage imbalance is becoming a more common problem.

In a 3-phase system, excessive voltage imbalance between phases will cause

motors to overheat and compressors to fail. Maximum allowable imbalance is

2%. To determine voltage imbalance, measure and record the voltage of all three

phases. Take the measurements at the compressor terminals with the compressor

operating.

Voltage Imbalance Formula:

Key:

V1, V2, V3 = line voltages as measured

VA (Average )= (V1 + V2+ V3) / 3

VD = Line Voltage (V1, V2, or V3 that deviates farthest from average (VA)

Formula:

% of Voltage Imbalance = [100 (VA - VD)] / VA

If the imbalance is within the 2% tolerance, voltage imbalance is not a problem and

the system may be operated. If the imbalance exceeds the 2% tolerance, follow

the procedures below.

Solutions to Voltage Imbalance:

The cause for a voltage imbalance problem can originate at the power company or

can be caused inside the building. Try the following on-site solution to determine if

the problem can be easily resolved.

Roll the connections at the compressor terminals one forward. Connect the wire

now on Terminal 1 to Terminal 2, 2 to 3, and 3 to 1. Re-measure and re-calculate

the voltage imbalance. If the imbalance is within 2%, the system may be operated.

If the imbalance is not within tolerance, roll the connections one more forward.

Re-measure and re-calculate the voltage imbalance. If the imbalance is within

2%, the system may be operated. If the voltage imbalance still exceeds 2%, do

not start the system. Contact the building owner or person responsible to have an

electrician analyze the buildings's power supply and load distribution.

Power Supply Voltage Phasing - Connect refrigerant pressure gauges to the

suction and discharge lines of the compressors and an electric meter to the power

supply.

3.6 Compressor

Maintenance

(cont'd)

3. Maintenance/

Service

Procedures

(cont'd)

□

Step 9. Charge the

System (cont'd))

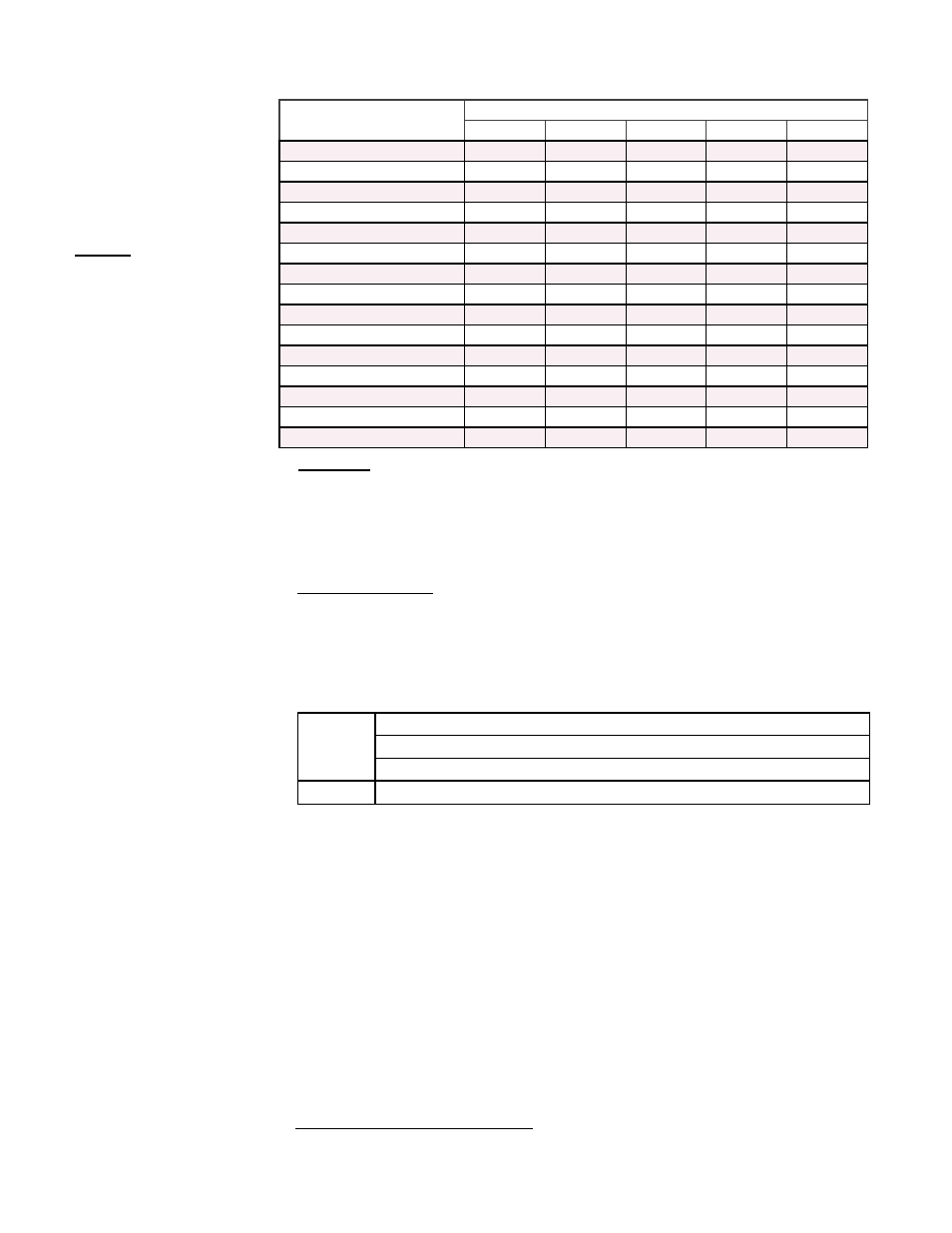

Approximate R410-A Refr

igerant Charge (lbs) by Model Size and

Compressor for Each Circuit (See FIGURE 5, page 12, to identify location.)

D Cabinet Models

and Size

Compressor Circuit

A

B

C

D

E or DH

RCB/RDCB/RECB 360

10.0

N/A

13.0

6.0

N/A

RCB/RDCB/RECB 480

10.0

13.0

13.0

N/A

N/A

RCB/RDCB/RECB 600

10.0

10.0

13.0

13.0

N/A

RCB/RDCB/RECB 720

13.0

13.0

13.0

13.0

N/A

RDB/RDDB/REDB 418

10.0

N/A

13.0

6.0

9.0

RDB/RDDB/REDB 444

10.0

N/A

13.0

6.0

9.0

RDB/RDDB/REDB 484

10.0

N/A

13.0

6.0

11.0

RDB/RDDB/REDB 538

10.0

13.0

13.0

N/A

9.0

RDB/RDDB/REDB 564

10.0

13.0

13.0

N/A

9.0

RDB/RDDB/REDB 602

10.0

13.0

13.0

N/A

11.0

RDB/RDDB/REDB 658

10.0

10.0

13.0

13.0

9.0

RDB/RDDB/REDB 684

10.0

10.0

13.0

13.0

9.0

RDB/RDDB/REDB 722

10.0

10.0

13.0

13.0

11.0

RDB/RDDB/REDB 804

13.0

13.0

13.0

13.0

9.0

RDB/RDDB/REDB 842

13.0

13.0

13.0

13.0

11.0