Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 39

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 39

Normal Furnace Operation Display

LED Display

Heat Mode

Description

OFF Mode (OFF)

System Idle - Control board has power, no faults found, no call for heat.

PURGE Mode (Pur)

System is purging the heat exchanger – No gas on, no flame, venter motor runs for the

specified purge timings. Purge cycles occur immediately before and after each burner

operation.

IGNITION Mode (Ign)

System is initiating burner operation – Ignitor energized, modulating valve moved to

ignition setting, gas on. Maintained for the trial-for-ignition period and the five-second

flame stabilization period.

WARM-UP Mode (HEA)

- (Board Self Check)

Period between Ignition and Run – System checks completed before modulation

control begins.

RUN Mode (run)

Normal modulating operation.

Ignition Retry (rEt)

System has had a failed ignition attempt or has lost flame during burner operation and

is beginning another ignition cycle.

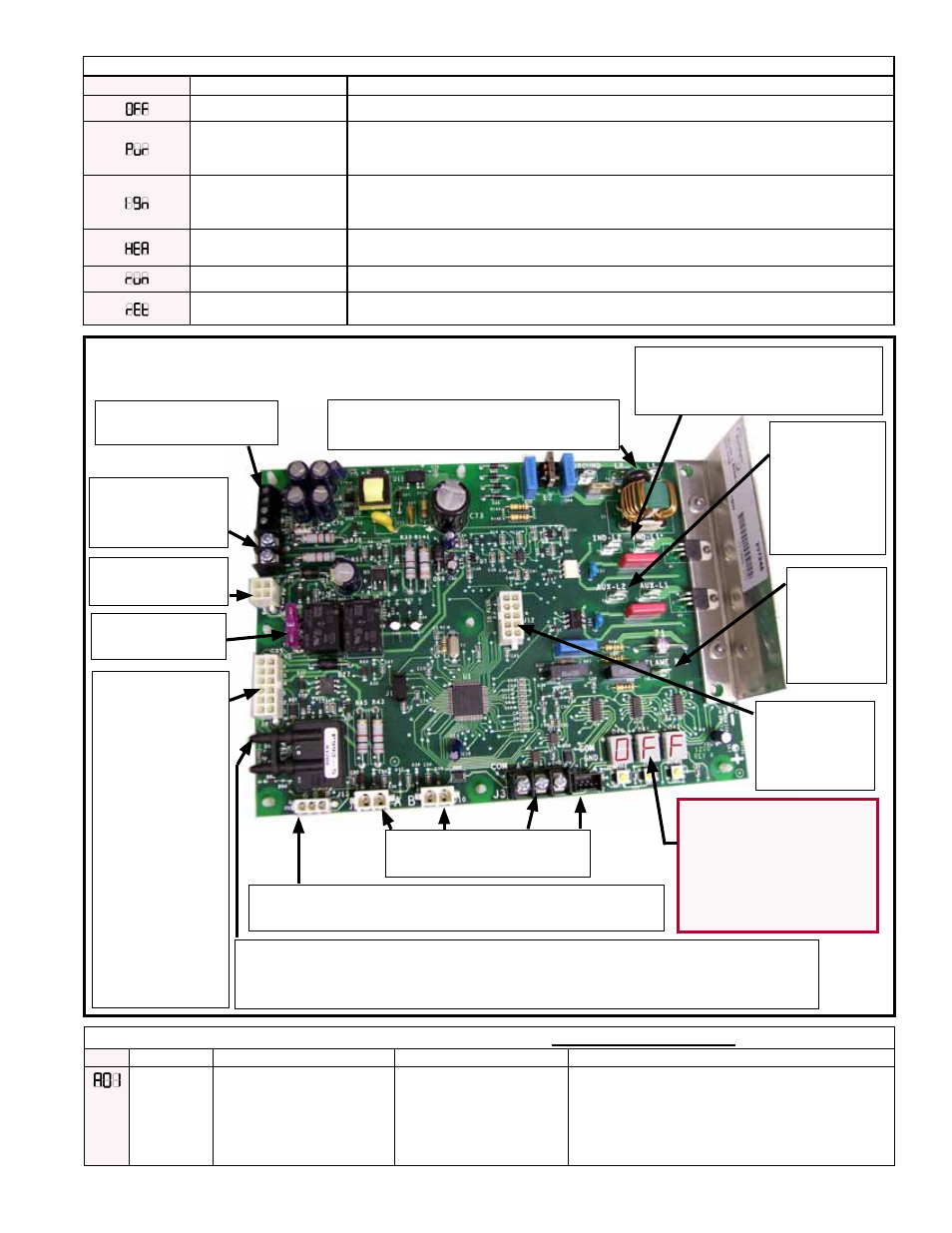

3 Character LED

Display used to show

deep modulation

board codes for

status, alarm, and

error information.

ID Plug

(unique by

heat section

size)

Deep Modulation (Option AG70) Ignition Board is in

the Heat Section (See FIGURE 12, page 25.)

IQ Controller Signal

Input Terminals (J4)

Board Status

Voltage Output

to IQ (J7)

Board Power

and Signal (J6)

Control Board

Fuse (3A)

Plug Connec-

tion for Board

Control Points

(J8)

• Ball Valve

Actuator Power,

Drive Voltage,

and Feedback

Signal

• Off Board

Digital Venter

Air Pressure

Switch and Unit

Primary Limit

Switch

On board Air Pressure Sensor for Monitoring Inducer Pressure.

Venter Sensing Tubing is connected from Venter housing to

"LO" pressure input point on air sensing transducer.

Gas Manifold PSI Transducer Plug 3-wire (red,

black, and green) Wiring Connection (J13)

J9, J10, J3, and J2 are

not currently used.

Flame

Sensor

Spade

Connec-

tion

(T8)

Inducer

Motor

Capacitor

Spade

Connection

(AUX-L2

T6

)

Inducer Motor Main Power

Connection Spades

(IND-L2

T3

and IND-L1

T2

)

Main Board Supply Power Input

Spades (L1

T1

and L2

T5

)

Gas Heat Section Modulating Control FUNCTIONAL ALERTS

Code

Alert

Description

Probable Causes

Solutions

Failed ignition

attempt (AO1)

Maximum

number of

allowed retries

not met

The flame could not be

established during the trial for

ignition period. This alert indicates

the maximum number of retries

has not been exceeded and

furnace operation will continue

with another ignition attempt.

See in the LOCKOUT ERRORS

section, pages 41-42.

See in the LOCKOUT ERRORS section, pages 41-42.