0 maintenance/ service procedures (cont'd), 2 drive components, 3 condenser fans – Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 6

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 6

3.0 Maintenance/

Service

Procedures

(cont'd)

3.2 Drive Components

Bearings - Bearings with a grease fitting should be lubricated twice a year with a high

temperature, moisture-resistant grease. (Type NLGI-1 or -2 standard grease is recom-

mended.) Be sure to clean the grease fitting before adding grease. Add grease with a

handgun until a slight bead of grease forms at the seal. Be careful not to unseat the

seal by over lubricating. NOTE: If unusual environmental conditions exist (tempera-

tures below 32°F or above 200°F; moisture; or contaminants), more frequent lubrica-

tion is required.

CAUTION: If the blower is unused for more than three months,

bearings with a grease fitting should be purged with new grease

prior to start-up.

Setscrews - Check all of the setscrews (bearing/blower hubs and pulleys). Torque pul-

ley setscrews a minimum of 110 in-lb to 130 in-lb maximum.

A bearing hub setscrew for a 1-3/8" to 1-3/4" shaft requires a 5/16" socket and a tight-

ening torque of 165 in-lbs.

Belts - Check belt for proper tension and wear. Adjust belt tension as needed. Replace

worn belts.

Blower systems are equipped with either Power Twist Plus

®

linked blower belt or a solid

belt. The linked belts are designed in sections allowing for easy sizing and adjustment.

The belt is sized at the factory for the proper tension. If the belt needs adjustment, the

recommended method of shortening the belt length is to count the number of links and

remove one link for every 24. (A link is made up of two joining sections of belt. For eas-

ier removal of links, turn the belt inside out. But be sure to turn it back before installing.)

If equipped with a solid belt, adjust the belt tension by turning the adjusting screw on

the motor base until the belt can be depressed 1/2" (13mm) on each side. After correct

tension is achieved, re-tighten the locknut on the adjustment screw.

Proper belt tension is important to the long life of the belt and motor.

Be sure belts are aligned in the pulleys. If a belt is removed or replaced, be sure to align

directional arrows on the belt to the proper drive rotation.

Motor and Blower - Inspect the motor mounts periodically. Remove dust and dirt accu-

mulation from the motor and wheel.

The blower has cast iron, pillowblock, sealed bearings. Under most operating condi-

tions, re-lubrication is unnecessary. If lubrication is required, use a lubricant compat-

ible to Shell Alvania #2 (lithium base - Grade 2). Operating temperature range is -30

to 230°F.

"D" size cabinets have plenum fan blowers which have an extension to the grease fit-

ting on the side of the fan assembly.

If any drive parts need to be replaced, use only factory-authorized replacements

designed for the application.

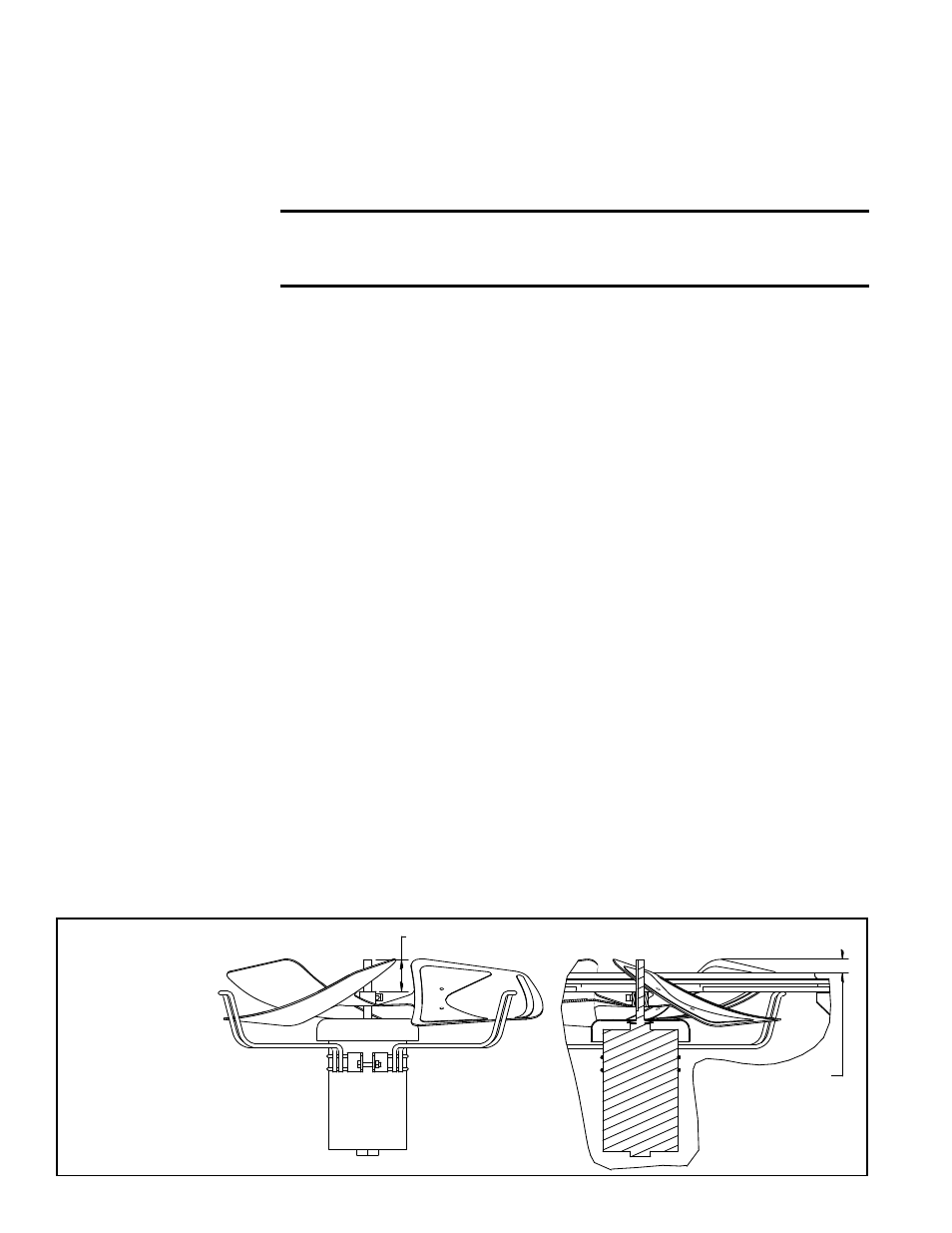

3.3 Condenser Fans

Depending on the size, there are two, three, or four fans in the condenser section. If

parts need to be replaced, use only factory authorized replacement parts.

See

FIGURE 3 for assembled dimensions and proper fan rotation direction.

2-1/2” (63.5mm)

Fan and Motor Assembly

showing Fan Blade Position

Cross-section of Installed Fan and Motor

Assembly showing Cabinet Top

1.76” (44.7mm)

Top of Fan Blade

to Top of the

Cabinet Top Panel

Fan rotation

is clockwise

FIGURE 3 -

Condenser

Fan Assembly

Dimensions

and Rotation