Caution, Maintenance/ service procedures (cont'd), 6 compressor maintenance (cont'd) – Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 18: 7 thermostatic expansion valves, Step 11 . check subcooling and superheat. (cont'd)

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 18

Follow the procedures in Paragraph 3.5 to check subcooling and superheat.

□

Step 12. (Select the procedure that applies.)

IF the oil measured in Step 2 was significantly less than in the table on

page 12 or the acid test in

Step 2 indicated a burnout, do the following:

a) Operate the unit for several hours. Check the pressure drop through the

temporary suction line filter drier. If the pressure drop exceeds 8 psig, recover

the refrigerant, replace the suction line filter drier with the same type as

removed, replace the liquid line filter drier, evacuate the circuit, and re-charge

with the recovered refrigerant.

Continue to monitor the pressure drop through the suction line filter drier and

repeat the process above until the pressure does not exceed 8 psig after

several hours of operation. (NOTE: System must be allowed to run no more

than 72 hours with a suction line filter drier.)

b) Allow the system to operate for 4-8 hours. Recover the refrigerant and take an

oil sample. Retest the oil for acid.

c) If the test for acid is negative, remove the suction line filter drier, replace

the liquid line drier, evacuate, and re-charge the system with the recovered

refrigerant.

If the test indicates acid, replace both the liquid line filter drier and the suction

line filter drier and repeat b) and c).

CAUTION:

After cleanup is complete, remove the suction line

filter drier. See Hazard Levels, page 2.

d) Verify subcooling and superheat (refer to

Step 11).

e) When the system is operating properly, remove the gauges.

IF the oil measured in Step 2 was not significantly less than that shown

in the table on page 12 or the acid test in

Step 2 did not indicate a

compressor burnout, continue to the review in

Step 13.

□

Step 13 . Review ALL Steps to ensure that nothing was

overlooked.

3.6 Compressor

Maintenance

(cont'd)

3. Maintenance/

Service

Procedures

(cont'd)

□

Step 11. Check Subcooling and Superheat. (cont'd)

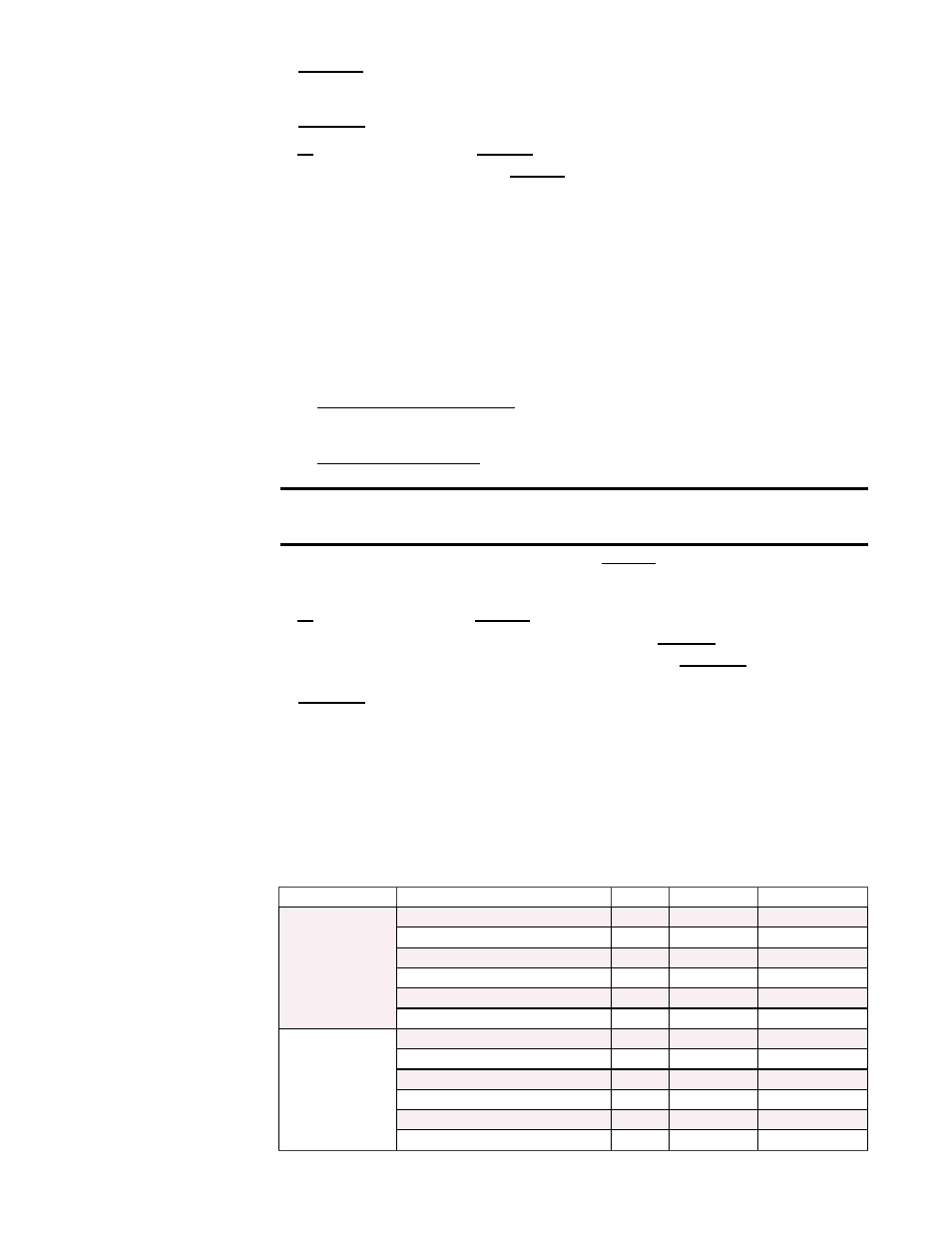

Model & Size

Compressor Circuit

P/N

Sporlan No. Connection Sizes

RCB/RDCB/RECB

360

RDB/RDDB/REDB

418/444/484

A

220556

BBIZE-8-GA

5/8x7/8x1/4

C

234987

BBIZE-4-GA

1/2x7/8x1/4

D

220558

BBIZE-15-GA

7/8x1-1/8x1/4

E or DH (RDB/RDDB/REDB 418 only)

234987

BBIZE-4-GA

1/2x7/8x1/4

E or DH (RDB/RDDB/REDB 444 only)

220555

BBIZE-6-GA

5/8x7/8x1/4

E or DH (RDB/RDDB/REDB 484 only)

220556

BBIZE-8-GA

5/8x7/8x1/4

RCB/RDCB/RECB

480

RDB/RDDB/REDB

538/564/602

A

220556

BBIZE-8-GA

5/8x7/8x1/4

C

220558

BBIZE-15-GA

7/8x1-1/8x1/4

D

220558

BBIZE-15-GA

7/8x1-1/8x1/4

E or DH (RDB/RDDB/REDB 538 only)

234987

BBIZE-4-GA

1/2x7/8x1/4

E or DH (RDB/RDDB/REDB 564 only)

220555

BBIZE-6-GA

5/8x7/8x1/4

E or DH (RDB/RDDB/REDB 602 only)

220556

BBIZE-8-GA

5/8x7/8x1/4

3.7 Thermostatic

Expansion

Valves

All refrigeration circuits have a thermostatic expansion valve. Thermostatic expansion

valves (TXV's) do not have replaceable parts. If a replacement valve is required, it

must be an R410-A valve and be sized correctly for the application. All refrigerant ser-

vice should be performed by a technician qualified in R410-A refrigerant.

Replacement valves by size and circuit are listed in the following table.