0 troubleshooting (cont'd) – Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 36

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 36

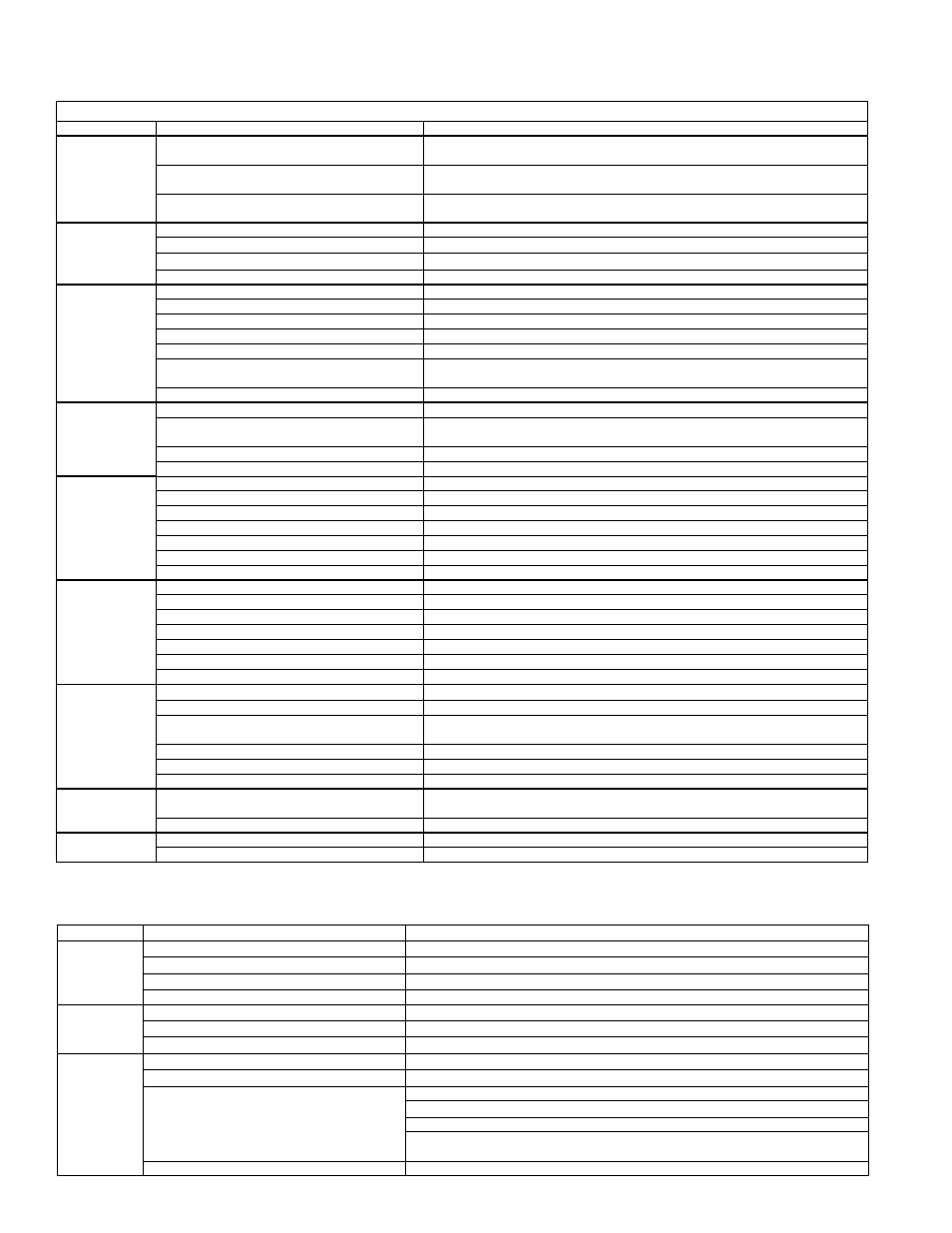

6.2 Troubleshooting Heat Section

6.2.1 General Troubleshooting - Electric Heat Section, Models RECB and REDB

PROBLEM

PROBABLE CAUSE

REMEDY

Unit does not

operate

1. No power to unit

1. Turn on power; check supply fuses or main circuit breaker.

2. Blown fuses

2. Check and replace if necessary.

3. Defective or incorrect wiring.

3. Check wiring and connections. Refer to wiring diagram provided with unit.

4. Defective or burned out control transformer 4. Check secondary voltage with voltmeter. Replace if necessary.

Fan operates

but element

does not heat

1. Dirty filters

1. Check filters and clean or replace if necessary.

2. Defective air proving switch

2. Check and replace if necessary.

3. Blown element fuses

3. Check and replace element fuses if necessary.

Insufficient

heat

1. Burned out element

1. Turn off power and check element resistance with ohmmeter. Replace if open.

2. Blown fuses

2. Check and replace if necessary.

3. Cycling on limit control

3.

a) Check air throughput (temperature rise).

b) Check motor rpm against nameplate rating. Replace motor if speed is too slow.

c) Defective limit control. Check wiring and connections. Check continuity through

control and replace if necessary.

4. Defective or incorrect wiring.

4. Check wiring and connections. Refer to wiring diagram provided with unit.

General Refrigeration Circuit - applies to all Models (cont'd)

SYMPTOM

POSSIBLE CAUSE

REMEDY

G. High suction

pressure

1. Excessive load on evaporator coil.

1. Check superheat (Paragraph 3.5). Check for high entering wet bulb temperature.

Check for excessive air.

2. Compressor is unloaded.

2. Check head pressure. Check thermal expansion valve. If valve is not functioning

properly, check pressure drop across filter drier.

3. Expansion valve bulb not secured to suction

line or valve defective.

3. Check the thermal expansion valve; ensure bulb is attached properly and

insulated

H. High discharge

pressure.

1. Refrigerant overcharge

1. Check subcooling. (Paragraph 3.5) Adjust refrigerant charge.

2. Thermal expansion valve setting

2. Check superheat and adjust valve as needed

.

2. Air inlet to condenser dirty or obstructed.

3. Check for proper clearances and possible air recirculating.

4. Condenser fan motor defective.

4. Check condenser fan motor(s).

I. Suction

pressure is too

low.

1. Refrigerant undercharge.

1. Check subcooling. (Paragraph 3.5) Add refrigerant as needed.

2. Thermal expansion valve setting

2. Check superheat and adjust valve as needed.

3. Blower running backward.

3. Interchange any two wires from 3 phase disconnect.

4. Loose blower, pulley, or belts.

4. Check drive pulley alignment and belt tension.

5. Dirty filter.

5. Check filter and evaporator coil.

6. Too little air flow or low entering air

temperature.

6. Check airflow and entering air wet bulb conditions.

7. Restriction in suction or liquid line.

7. Check refrigerant circuit for restriction.

J. Head pressure

too low.

1. Insufficient refrigerant charge.

1. Check subcooling (Paragraph 3.5). Check for leak. Repair and add refrigerant.

2. Defective or improperly adjusted expansion

valve.

2. Check superheat (Paragraph 3.5) and adjust thermal expansion valve.

3. Low suction pressure.

3. See “I. Suction pressure too low” above.

4. Defective compressor.

4. See "G. High suction pressure” above.

K. Compressor

short cycles.

1. Improper refrigerant charge.

1. Check subcooling and superheat. (Paragraph 3.5)

2. Defective high or low pressure control.

2. Check high or low pressure switch.

3. Liquid floodback.

3. Possible tight bearings, see above.

4. Defective expansion valve.

4. Check superheat and thermal expansion valve.

5. Poor air distribution.

5. Check ductwork for recirculating.

6. High discharge pressure.

6. See “H. High discharge pressure” above.

7. Leaking discharge valves in compressor.

7. See “G. High suction pressure” above.

L. Running cycle

is too long or

unit operates

continuously.

1. Refrigeration undercharged.

1. Check subcooling (Paragraph 3.5) and add refrigerant.

2. Dirty filter or evaporator coil.

2. Check filter, coil, and airflow. Clean and/or replace.

3. Dirty or clogged condenser coil.

3. Check coil and airflow. Clean.

4. Air or other non-condensables in system.

4. Check equalized high side pressure with equivalent outdoor temperature.

5. Defective compressor.

5. See “G. High suction pressure” above.

6. Restriction in suction and liquid line.

6. Check for restrictions in refrigerant circuit.

7. Control contacts stuck.

7. Check wiring.

M. Supply air

temperature is

too high.

1. Refrigerant undercharge or leak in system.

1. Check subcooling

(Paragraph 3.5). Check for leak. Repair and add refrigerant.

2. Evaporator plugged with dirt or ice.

2. Check evaporator, airflow, and filter. Clean.

3. Improperly adjusted or defective expansion

valve.

3. Check superheat (Paragraph 3.5) and adjust thermal expansion valve. Check

expansion valve bulb placement and insulation.

4. Defective compressor.

4. Check compressor for proper operation.

5. High discharge pressure.

5. See “H. High discharge pressure” above.

6. Airflow is too high.

6. Check external static pressure.

N. Supply air

temperature is

too low.

1. Airflow is too low.

1. Check evaporator coil; check filters; check for closed dampers or grills; check

drive for loose parts, belts, or misalignment; and check external static pressure.

2. Return air temperature too low.

2. Check entering air wet bulb conditions.

O. Liquid line is

too hot.

1. Refrigerant undercharge.

1. Check subcooling.

2. High discharge pressure.

2. See H. above.

6.1 Troubleshooting - RCB, RDB, RDCB, RDDB, RECB, REDB

(cont'd)

6.0 Troubleshooting

(cont'd)