Compressor model and p/n by tonnage and voltage – Reznor MAPS III, Cabinet D RECB Users Manual User Manual

Page 13

Form O-MAPSIII Cabinet D, P/N 222918R9, Page 13

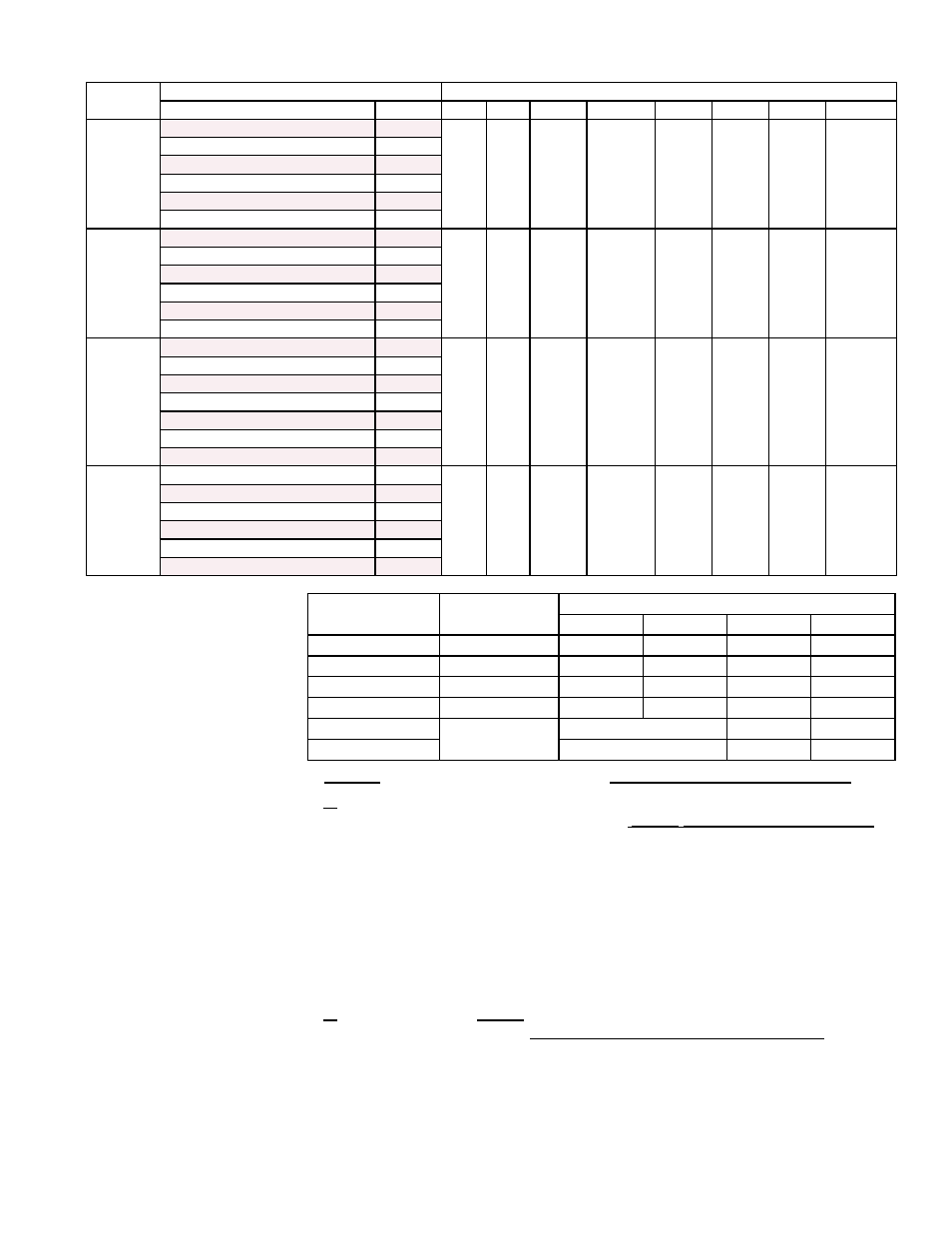

MAPSIII

Cabinet D

Compressor

Cooling Staging

Circuit

Tonnage

1

2

3

4

5

6

7

8

360

418

444

484

A

10

C

A

A+C

D

C+D

A+C+D

C

5

D

15

DH or E (RDB/RDDB/REDB 418)

5

DH or E (RDB/RDDB/REDB 444)

7

DH or E (RDB/RDDB/REDB 484)

10

480

538

564

602

A

10

A

D

A+D

C+D

A+C+D

C

15

D

15

DH or E (RDB/RDDB/REDB 538)

5

DH or E (RDB/RDDB/REDB 564)

7

DH or E (RDB/RDDB/REDB 602)

10

600

658

684

722

A

10

B

D

A+B

A+D

C+D

A+B+D B+C+D A+B+C+D

B

10

C

15

D

15

DH or E (RDB/RDDB/REDB 658)

5

DH or E (RDB/RDDB/REDB 684)

7

DH or E (RDB/RDDB/REDB 722)

10

720

804

842

A

15

B

B+C B+C+D A+B+C+D

B

15

C

15

D

15

DH or E (RDB/RDDB/REDB 804)

7

DH or E (RDB/RDDB/REDB 842)

10

Compressor Staging for Cooling (applies to Models RCB, RDB, RDCB, RDDB RECB, REDB)

Compressor

Model

ARI Tonnage

Compressor P/N

208V

230V

460V

575V

ZP57K3E

5

216686

216686

216687

216688

ZP83KCE

7

216689

216689

216690

216691

ZP120KCE

10

216695

216695

216696

216697

ZP182KCE

15

216454

216454

216455

216456

Wiring Harness

One each for each

compressor

P/N 223028

P/N 223029 P/N 223030

Crankcase Heater

P/N 216402

P/N 216404 P/N 216405

Compressor Model

and P/N by Tonnage

and Voltage

□

Step 4. Install New Filter Driers (Select procedure that applies.)

IF the oil measured in Step 2 was not significantly less than the amount shown

in the table on page 12 or the test for acid in

Step 2 did NOT indicate burnout ,

install a new R-410A refrigerant liquid line filter drier. The filter drier must be rated

for no less than 600 psig and be the proper size for the circuit. Because R-410A

refrigerant requires POE oil which absorbs moisture quickly, it is important to

change the filter drier any time the circuit is opened.

It is recommended to use a tubing cutter when cutting out a filter drier as the

desiccant absorbs and holds moisture better when it is cool. Heat from a torch may

cause moisture to leave the filter and be absorbed in the oil. Be careful to keep

dirt, filings, and other contaminants out of the system.

Continue to

Step 5.

IF the oil measured in Step 2 was significantly less than shown in the table on

page 12 or the test for acid in

Step 2 did indicate compressor burnout, do the

following:

a) Install a liquid line filter drier.

If there is acid, install an acid removing filter drier.

Size the acid-removing filter drier at least one capacity size larger than normally

required for the circuit.

b) Install a temporary filter drier in the suction line. When there is acid, a 100%

activated alumina suction filter drier is recommended. The suction line drier

should be sized properly for the circuit and have a service access fitting to