6 interlock tests, Benchmark 2.0ln low nox boiler, Gf-123 – AERCO BMK 2.0 LN Natural Gas (SN G-11-1861 and above) User Manual

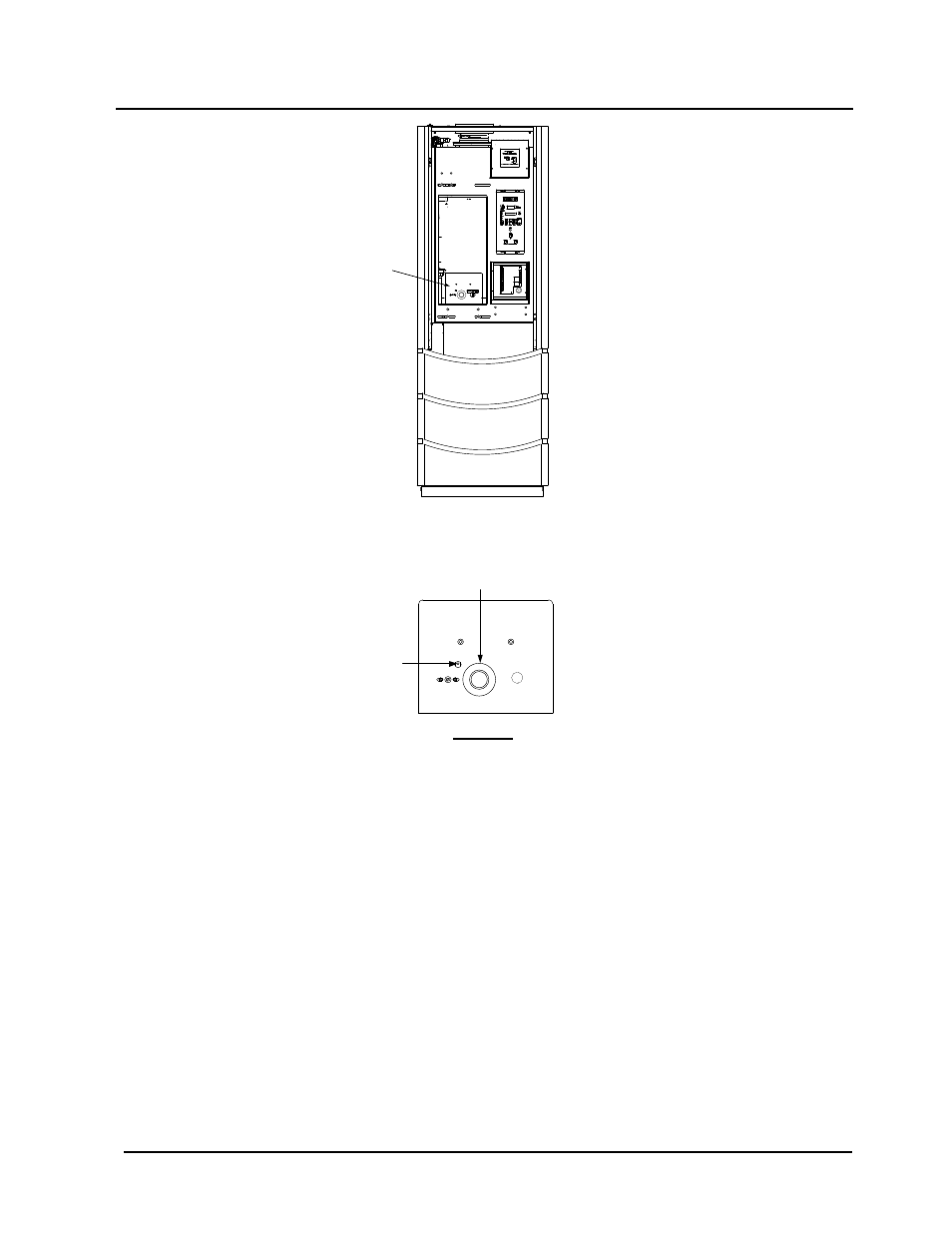

Page 76: Figure 6-2: temperature limit switch setting

Chapter 6

Benchmark 2.0LN Low NOx Boiler

GF-123

Safety Device Tests

Installation, Operation and Maintenance Manual

OMM-0046_0E

Page 76 of 170

AERCO International Inc.● 100 Oritani Dr. ● Blauvelt, NY 10913. ● Ph: 800-526-0288 PR1 08/20/12

FRONT VIEW

ADJUSTABLE

TEMPERATURE

LIMIT SWITCH

RESET BUTTON

FOR MANUAL

TEMPERATURE

LIMIT SWITCH

SEE

DETAIL “A”

DETAIL “A”

Figure 6-2: Temperature Limit Switch Setting

6. Once the adjustable over-temperature switch setting is approximately at, or just below, the

actual outlet water temperature, the unit should shut down. The FAULT indicator should

start flashing and a HIGH WATER TEMP SWITCH OPEN fault message should be

displayed. It should not be possible to restart the unit.

7. Reset the adjustable over-temperature switch to its original setting.

8. The unit should start once the adjustable temperature limit switch setting is above the actual

outlet water temperature.

6.6 INTERLOCK TESTS

The unit is equipped with two interlock circuits called the Remote Interlock and Delayed

Interlock. Terminal connections for these circuits are located in the I/O Box (Figure 2-9) and are

labeled REMOTE INTL’K IN and DELAYED INTL’K IN. These circuits can shut down the unit in

the event that an interlock is opened. These interlocks are shipped from the factory jumpered

(closed). However, each of these interlocks may be utilized in the field as a remote stop and

start, an emergency cut-off, or to prove that a device such as a pump, gas booster, or louver is

operational.