Transaxle orientation, 4 x 2 drive system - (steel bed) – Cub Cadet 4 x 2 Big Country - Poly Bed & Steel Bed User Manual

Page 65

4 X 2 Drive System - (Steel Bed)

61

10.

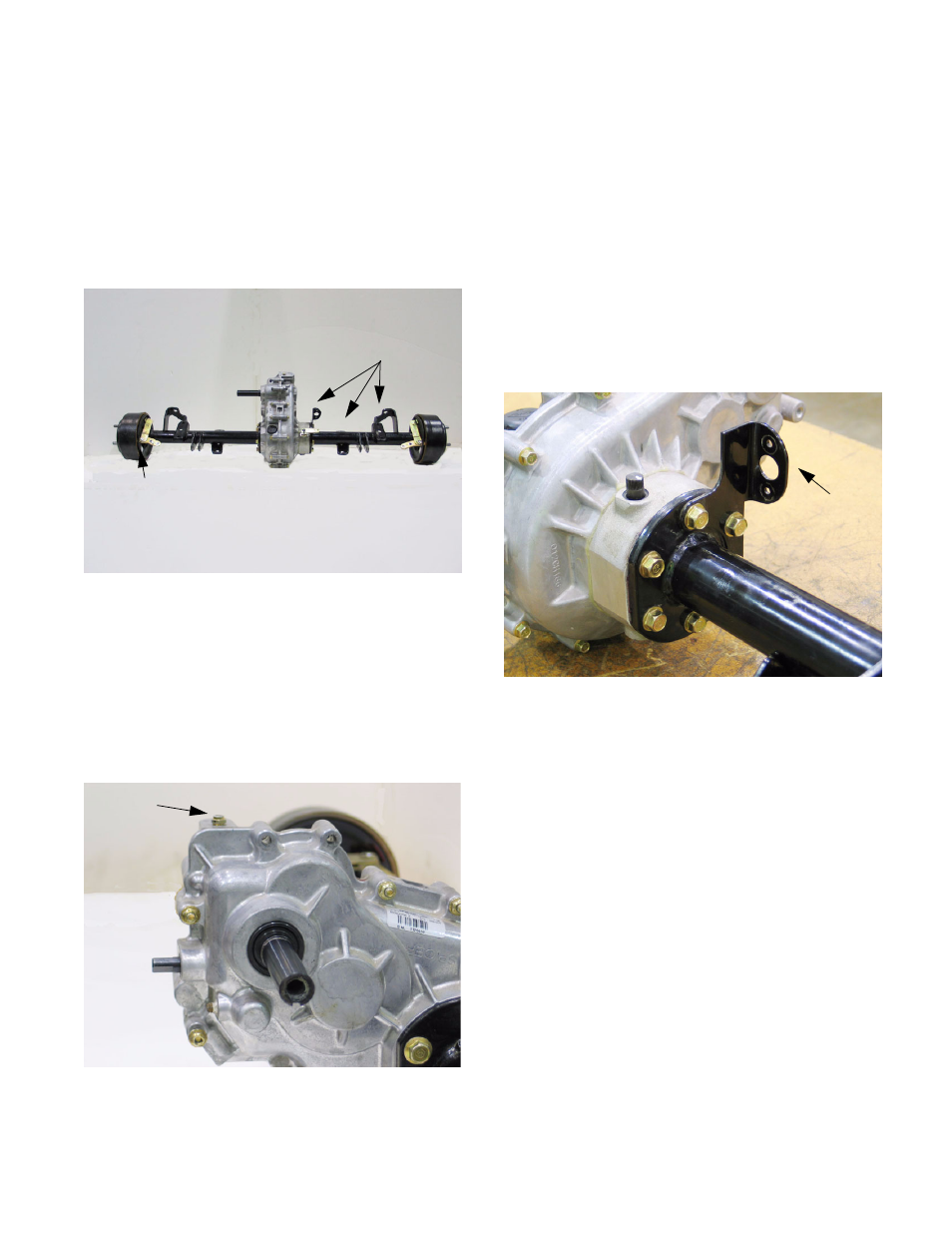

TRANSAXLE ORIENTATION

10.1. The transaxle is a Dana / Spicer model H12

FNR. Before disassembly, become familiar with

and match-mark the components to establish

orientations for assembly.

10.2. This is a bench procedure. For any internal

repairs, the transaxle must be removed from the

vehicle. See Figure 10.2.

10.3. Viewing the transaxle as it would be oriented in

the utility vehicle, with the input shaft to the left

hand side and the black rubber fill / check plug

facing up, directly above the axle tubes:

10.4. The vent valve is on the top of the right-side

housing. Remove it using a 7/16” wrench.

See Figure 10.4.

Figure 10.2

Front

Rear

Brake Clevis

Brackets

Figure 10.4

Vent

10.5. The top two holes for the bolts that connect the

left and right halves of the housing will be

vacant. The bracket that supports the vacuum

reservoir, the F-N-R actuator, and the neutral

switch is secured to these points. The bracket is

also bolted to two mounting bosses on the front

of the right side housing.

10.6. If not previously removed, take-off the bracket

for the differential lock actuator using a 9/16”

wrench. It is held by the same bolts that hold the

right side axle tube and differential lock housing

to the transmission housing. The mounting

flange on the bracket should be vertical, toward

the front of the transaxle. See Figure 10.6.

10.7. If not previously removed, the differential lock

lever should be parallel to the axle tubes, with

the clamp bolt to the rear when the differential

lock is engaged (lever pulled forward). It may be

necessary to rotate one of the axle shafts while

applying light forward force to the lever to

engage the differential lock. The lever is easily

removed using a pair of 7/16” wrenches.

10.8. The axle tubes are oriented so that the brake

actuators are at the top, and the brake cable

brackets extend toward the front of the vehicle.

The flats on the mounting flanges at the inboard

end of both axle tubes align with the flats on the

housing.

NOTE: The left side axle is roughly 1 3/4”

shorter than the right (differential lock) side.

NOTE: The axle bearings are greased, with

sealed bearings at each end. They are not lubri-

cated by the oil within the housing.

Figure 10.6

Differential

Lock

Bracket