Poly bed 4 x 2 drive system – Cub Cadet 4 x 2 Big Country - Poly Bed & Steel Bed User Manual

Page 36

Poly Bed 4 X 2 Drive System

32

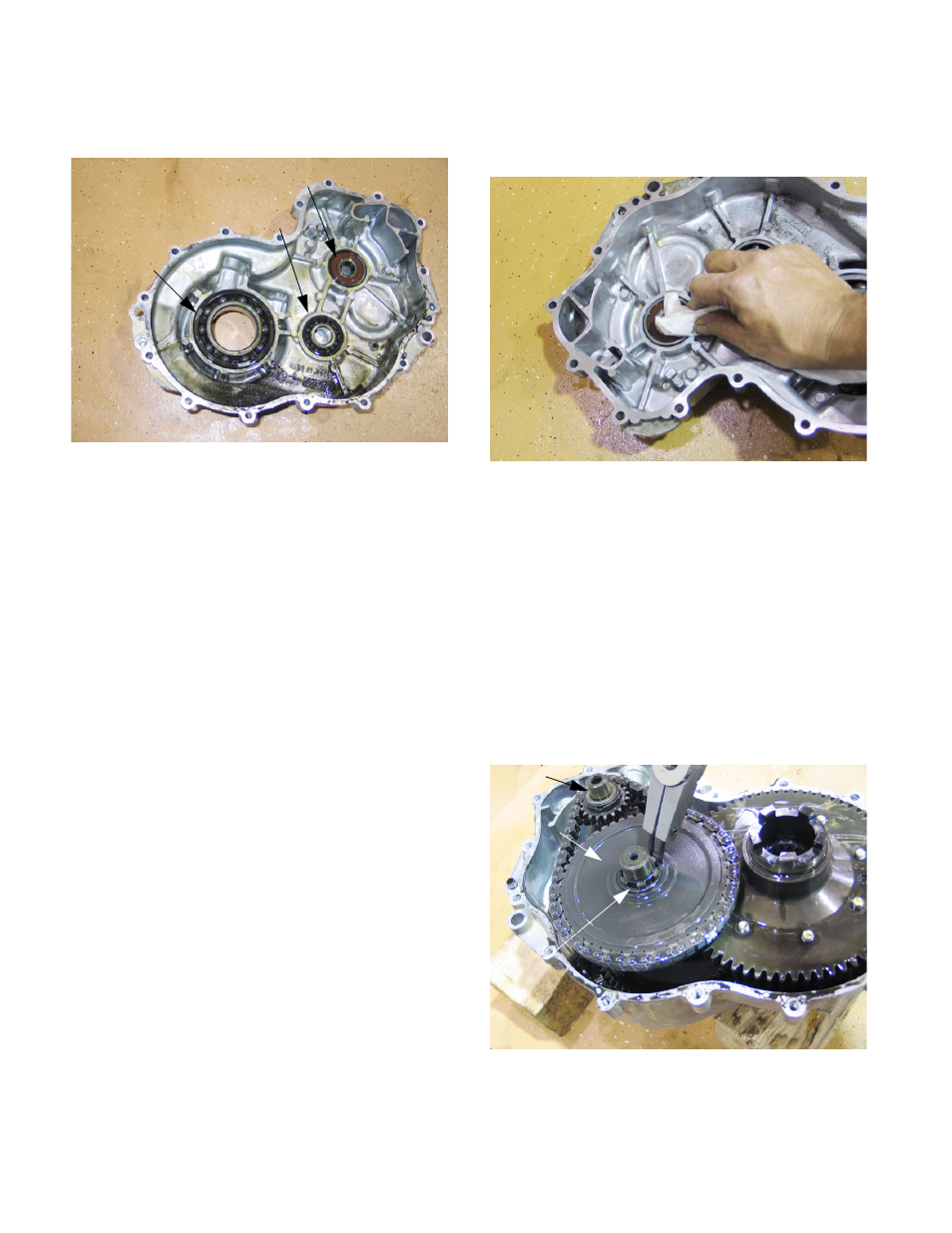

9.31. Clean the left half of the housing, and inspect the

three bearings that reside in it. See Figure 9.31.

•

The largest bearing supports the differential. It

may be driven out of the housing from the out-

side-in.

•

The nose of the input shaft rides in a sealed

bearing in a blind hole.

•

The reduction shaft is supported by an open ball

bearing in a blind hole.

•

A blind bearing puller may be necessary to

remove the input shaft bearing and the reduction

shaft bearing.

•

Heating the housing evenly to 200 degrees f.

(93 deg. c.) will cause it to expand, making bear-

ing removal and replacement easier. This

should be done in an oven or by immersion in

hot oil. Do NOT heat the housing with a torch.

The un-even application of heat will cause it to

distort.

9.32. Be certain to remove all of the cleaning solvent

before heating the housing or reassembling the

transaxle. See Figure 9.32.

•

The solvent may be present hazards when

heated.

•

The solvent will severely contaminate the gear

lube on assembly, causing a lubrication related

transaxle failure.

•

The solvent tends to get trapped behind the

sealed bearing.

9.33. Remove the 25 mm circlip that secures the 51-

tooth reverse sprocket to the reduction shaft

using a pair of retaining ring pliers.

See Figure 9.33.

9.34. Remove the thrust washer (17.3mm I.D.X 30mm

O.D.X 1.4mm thick) from the input shaft.

Figure 9.31

Sealed bearing for input hsaft, blind

Ball bearing for red.shaft, blind

Differential

bearing

Figure 9.32

Clean any solvent

from behind

sealed bearing

Figure 9.33

Thrust

washer

Circlip

Reverse

sprocket