Poly bed 4 x 2 drive system – Cub Cadet 4 x 2 Big Country - Poly Bed & Steel Bed User Manual

Page 34

Poly Bed 4 X 2 Drive System

30

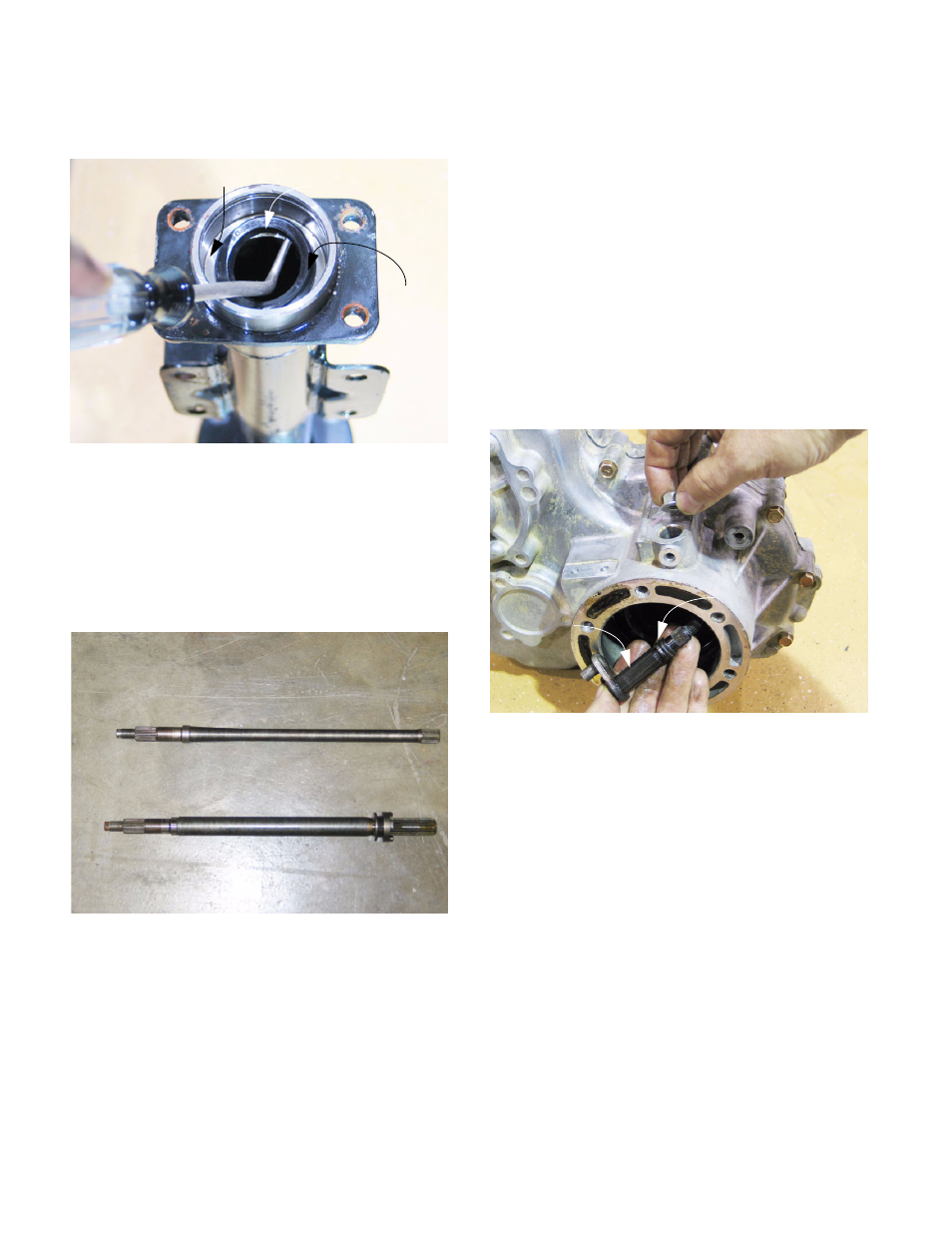

9.20. Remove the seal from the axle tube.

NOTE: The oil seal seats against a shoulder in

the tube. Hook the seal removal tool under the

lip of the seal to avoid scratching the bore that

the seal fits in.

9.21. Technical Info. for the Curious:

•

The weakest part of a splined shaft is at the root

of the spline. That is the smallest cross-section

of the shaft and the root of the spline creates

stress risers.

•

The right side axle is necked-down in the middle,

to a size that is smaller than the root of the

spline.

•

The necked-down axle shaft spreads the force

over a wider area, allowing the shaft to twist over

a greater portion of its length when torque is

applied to it. This reduces the load on the weak-

est part of the shaft: the root of the spline.

9.22. Clean the axle tubes, and inspect them for:

•

Bends, cracks, or crushes.

•

Scratches or damage to mating surfaces.

9.23. Check the bearings for damage: looseness and

coarseness. Check the shafts for damage to the

splines, threads, bearing seat, and seal surface.

9.24. To remove the differential lock arm from the tran-

saxle housing, simply push it down into the bore.

See Figure 9.24.

9.25. Remove and discard the O-ring seal in the upper

groove on the differential lock arm.

NOTE: If the differential lock failed to disengage

under the pressure of the torsion return spring,

and the linkage moves freely, check the fit

between the shaft of the arm and the bore.

NOTE: Symptoms of a differential lock stuck in

the engaged position include squealing tires

when making turns at even modest speeds on

pavement, and complaints that the front end

“plows” or the ability to turn the vehicle in tight

quarters has diminished.

NOTE: Wear limits for differential lock shift

mechanism:

•

Maximum groove width is 9.2mm (.36”)

•

Minimum shift pin diameter: 8.3mm (.33”)

•

Dogs should not have rounded or broken teeth.

Figure 9.20

Seal

Shoulder for seal

Shoulder for bearing

Figure 9.21

Figure 9.24

Differential

lock arm

O-ring

seal