Poly bed 4 x 2 drive system – Cub Cadet 4 x 2 Big Country - Poly Bed & Steel Bed User Manual

Page 23

Poly Bed 4 X 2 Drive System

19

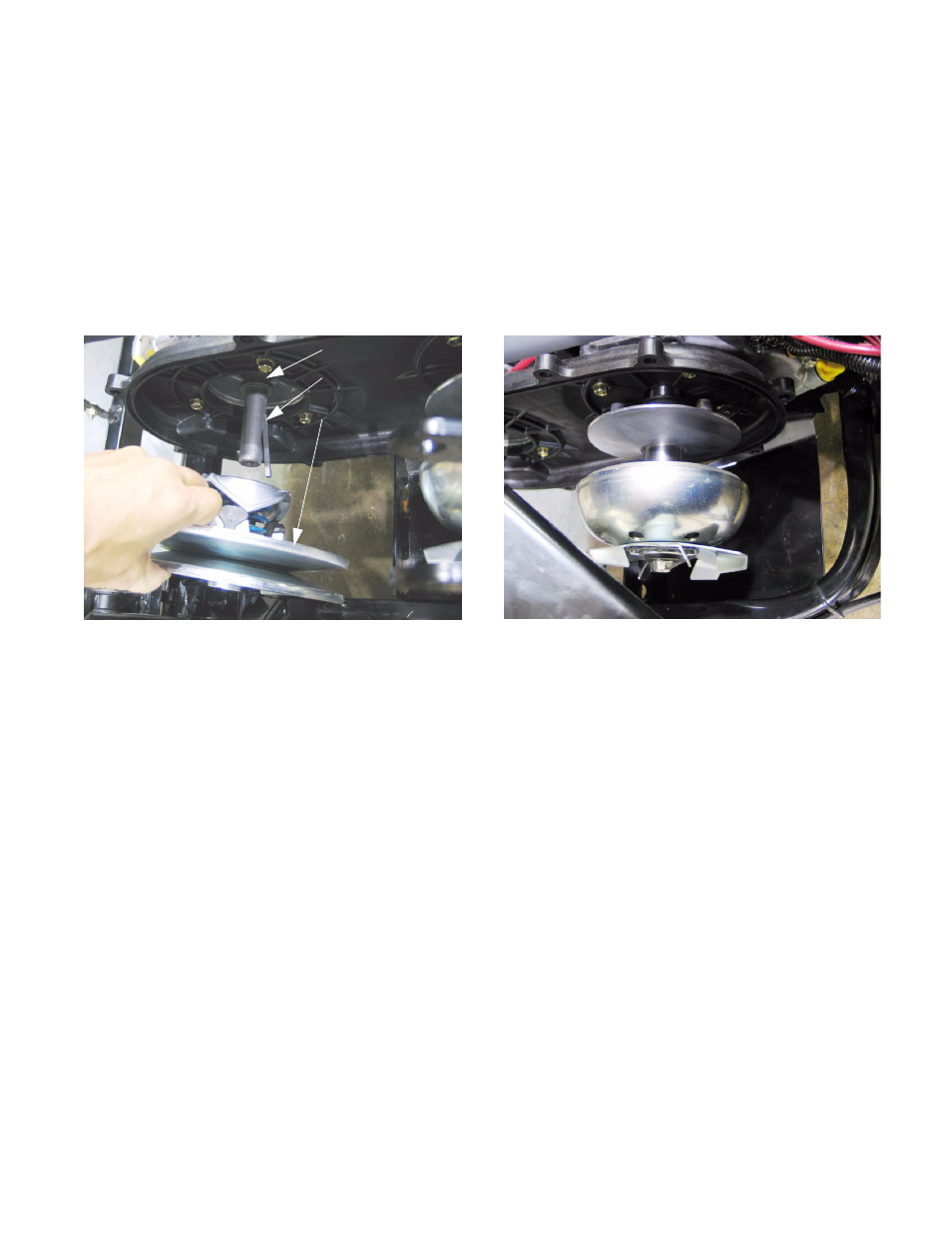

5.50. After the belt is removed, the driven pulley can

be removed: See Figure 5.50.

•

Take the bolt and washer that secure the pulley

onto the transaxle input shaft completely off

using a 12 mm wrench.

•

Slide the pulley off of the input shaft. It may be

necessary to carefully pry on the pulley hub.

•

There is a key between the pulley and the input

shaft, and a spacer between the pulley and the

shoulder on the input shaft.

5.51. If the driven pulley does not function properly,

replace it as a complete unit.

5.52. On installation:

•

Apply a small amount of anti-seize compound to

the input shaft.

•

Confirm that the spacer and key are properly

positioned. The chamfered side of the spacer

should face the shoulder on the crankshaft.

•

Slip the driven pulley all the way onto the input

shaft, and seat it against the spacer.

•

Apply a small amount of thread locking com-

pound such as Loctite 242 (blue) to the threads

of the bolt.

•

Secure the pulley to the input shaft with the bolt

and washer. Tighten the bolt to a torque of: 24 ft-

lb (32 N-m).

5.53. Key points to inspect on the driven pulley are the

ramp surfaces on the cams, and the polymer

buttons that ride against the ramps.

Figure 5.50

Spacer

Key

Driven pulley

5.54. After the belt is removed, the driving pulley can

be removed: See Figure 5.54.

•

Remove the bolt and washer securing the driv-

ing pulley to the engine crankshaft using a 14

mm wrench.

•

Slide the driving pulley off of the crankshaft.

•

There is a key between the pulley and the input

shaft, and a spacer between the pulley and the

shoulder on the crankshaft. The spacer is

notched to fit over the key.

5.55. If the driven pulley does not function properly,

replace it as a complete unit.

5.56. On installation:

•

Apply a small amount of anti-seize compound to

the crankshaft.

•

Confirm that the spacer and key are properly

positioned. The chamfered side of the spacer

should face the shoulder on the crankshaft. The

key should fit through the notch in the spacer.

•

Slip the driven pulley all the way onto the input

shaft, and seat it against the spacer.

•

Apply a small amount of thread locking com-

pound such as Loctite 242 (blue) to the threads

of the bolt.

•

Secure the pulley to the input shaft with the bolt

and washer. Tighten the bolt to a torque of: 31 ft-

lb (42 N-m).

Figure 5.54