Τ = 2√τ – Brookfield DV2+Pro Viscometer User Manual

Page 63

Brookfield Engineering Labs., Inc.

Page 63

Manual No. M03-165-F0612

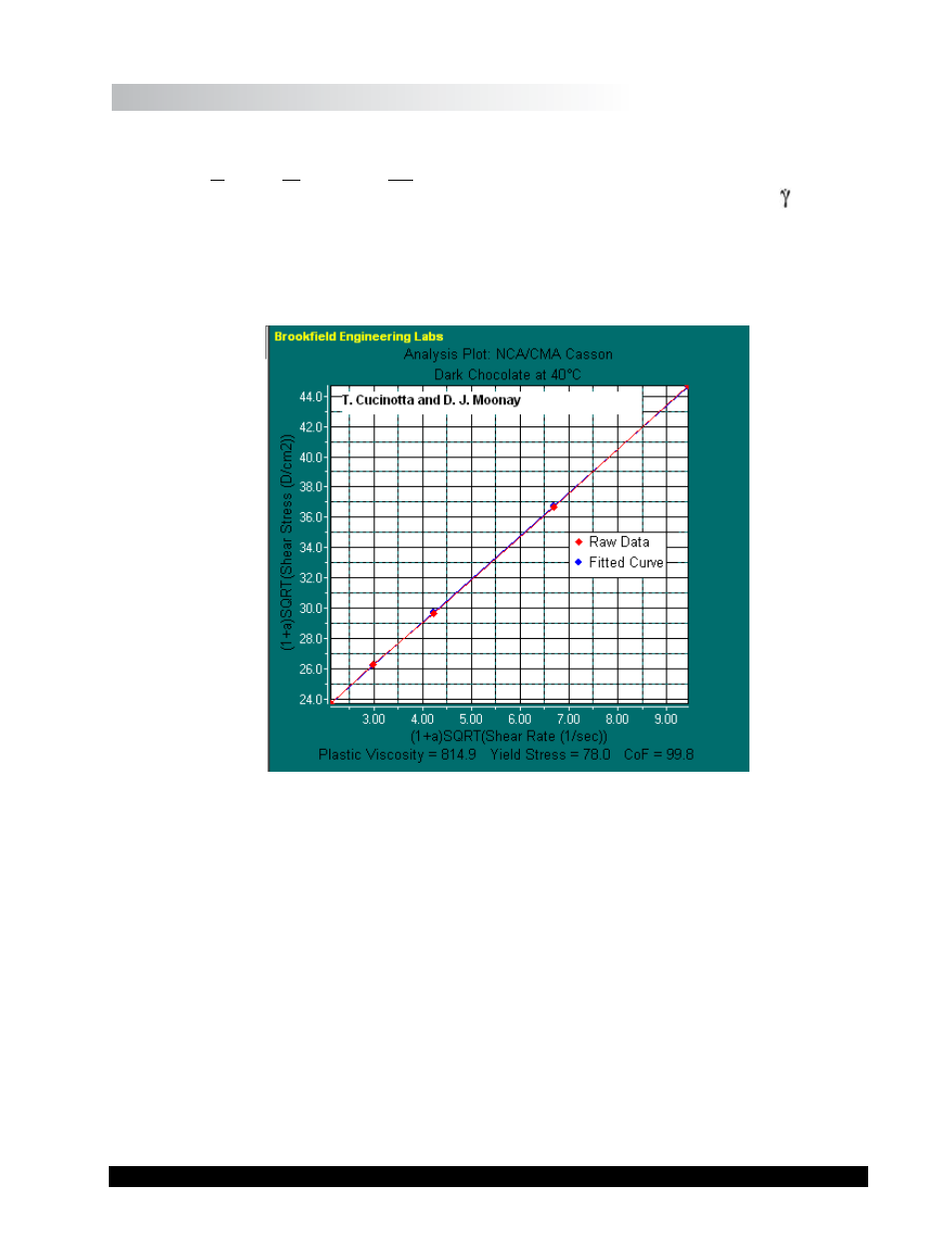

V1.3.5 Other Common Rheological Models

The NCA/CMA Casson Model

(1 +

a)

√τ = 2√τ +

(1 +

a)

√ηγ

°

⋅

(

τ

= shear stress

,

τ

°

= yield stress,

h

= plastic viscosity, and

= shear rate)

The NCA/CMA Casson model is designed by the National Confectioners Association and the

Chocolate Manufacturers Association as the standard rheological model for the industry. This

model determines yield and flow properties under specified conditions and closely approximates

the plastic behavior of chocolate before final processing.

Figure V1-18

When chocolate is used for enrobing, it must have a yield stress high enough to stay in place once

it enrobes the filling. In the case of decorating chocolate, the yield stress must be high enough so it

can keep its shape once it has been squeezed into place through a nozzle. For molding chocolate,

the plastic viscosity must be low enough to completely fill the mold.

(The NCA/CMA lists Brookfield’s HA-spring range viscometer with a Small Sample Adapter,

SC4-27 spindle and SC4-13R sample chamber as the approved apparatus.)

The IPC Paste Model

h

=kR

n

The IPC Paste Model was developed for solder pastes. It calculates the viscosity of solder pastes

at 10rpm. The IPC Paste Model requires that the product be tested with a Brookfield Spiral

Adapter at multiple speeds. More details can be found in the IPC-TM-650 Test Methods Manual

(methods 2.4.34.2 and 2.4.3).