HP 2566C User Manual

Page 111

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

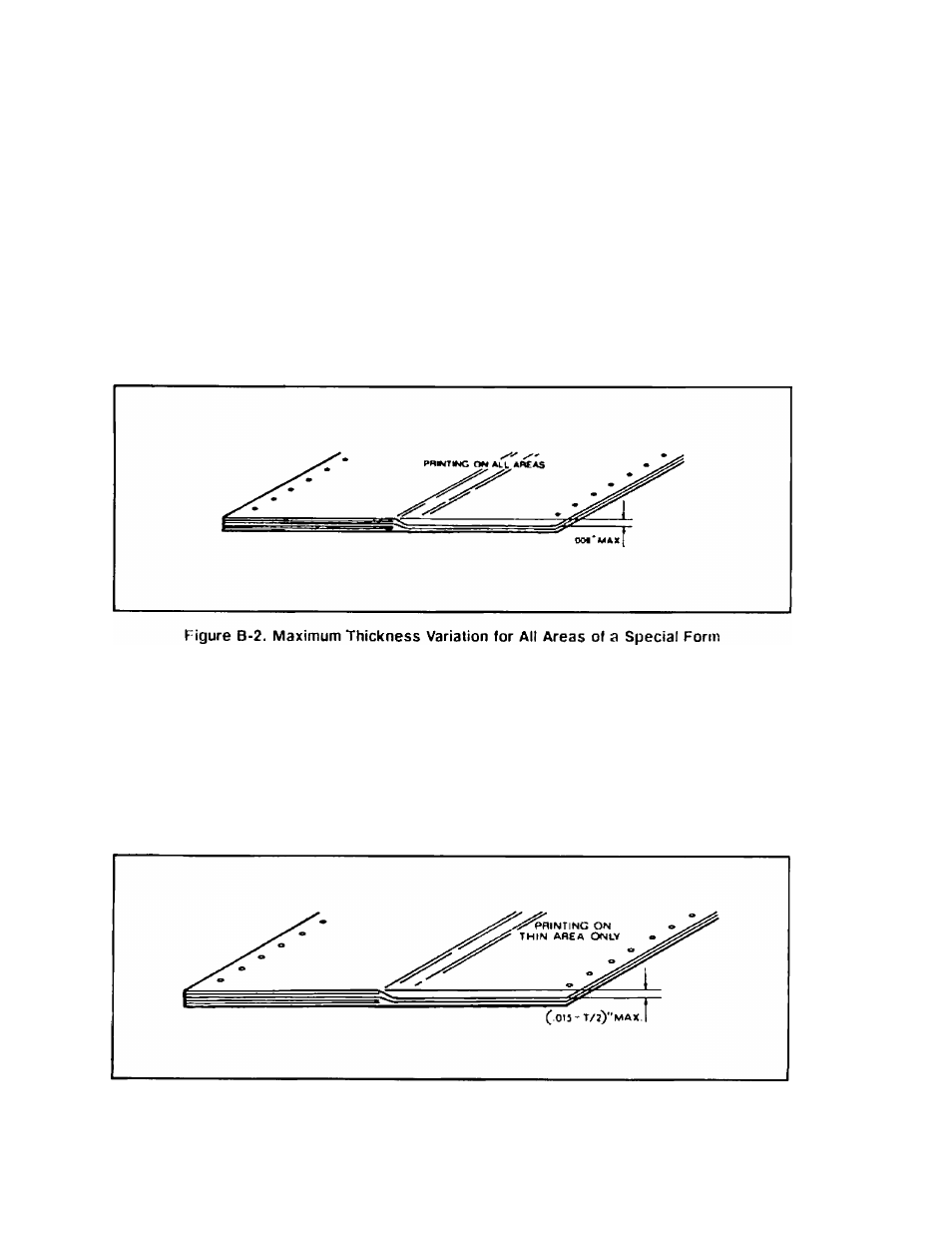

In order to ensure satisfactory print quality on all areas of the form, the

difference in thickness between the thickest and thinnest section of the

form should be no more than .008 inch (as shown in Figure B-2). The

print gap should be adjusted to optimize print quality on all thicknesses

of the form.

Since dot-matrix printing is optimized when printing at one gap size,

print quality can, in some cases, be compromised when printing on

forms of varying thickness. This is especially true on the copy sheets

of multi-part forms. When printing on forms of varying thickness, the

maximum depth of depression defects on the thick part of the form is

also .008 inch.

Case 2: Varying Thickness Forms: Printing on Aii Areas.

Case 3: >^rying Thickness Forms: Printing on Thin Areas

In order to avoid smearing on the thickest area of the form when

printing on the thin area only, the difference in thickness between

the thinnest area and the thickest should be no more than as shown

in Figure B-3 (.015-T/2; T=thickness) inch. For forms with larger

variations in thickness, the print gap may he opened beyond the

optimum gap to reduce smearing, but print quality on the thinner areas

will degrade accordingly.

Figure B-3. Maximum Thickness Variation for the Thin Areas of a Special Form

B-4 PAPER SPECIFICATIONS