Speciality forms specifications – HP 2566C User Manual

Page 110

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Speciality Forms

Specifications

This section of paper specifications is intended to familiarize and

alert the user to some of the characteristics of specialty forms which

may cause unsatisfactoiy performance of the printer. This paper

specification is NOT intended as a substitute for actual testing.

Note

All specially forms, including special single-part paper, multi-part forms,

forms with glue strips, carbonless forms, card stock, and labels should

be tested for satisfactory feeding, registration, and print quality prior to

purchase.

Form Thickness

Uniformity

Because of the small print gap in dot-matrix printers, these printers

are less tolerant of form thickness variations than are full-font printers.

Sometimes these thickness variations can he caused by defects such

as hubbies or wrinkles. Other times they are due to varying paper

composition or the number of parts within the form.

Nominal differences in thickness and compressibility make it impossible

to specify allowable thickness variations exactly. The following cases are

intended to serve as a guide, but all forms width thickness variations

must be tested for satisfactory performance.

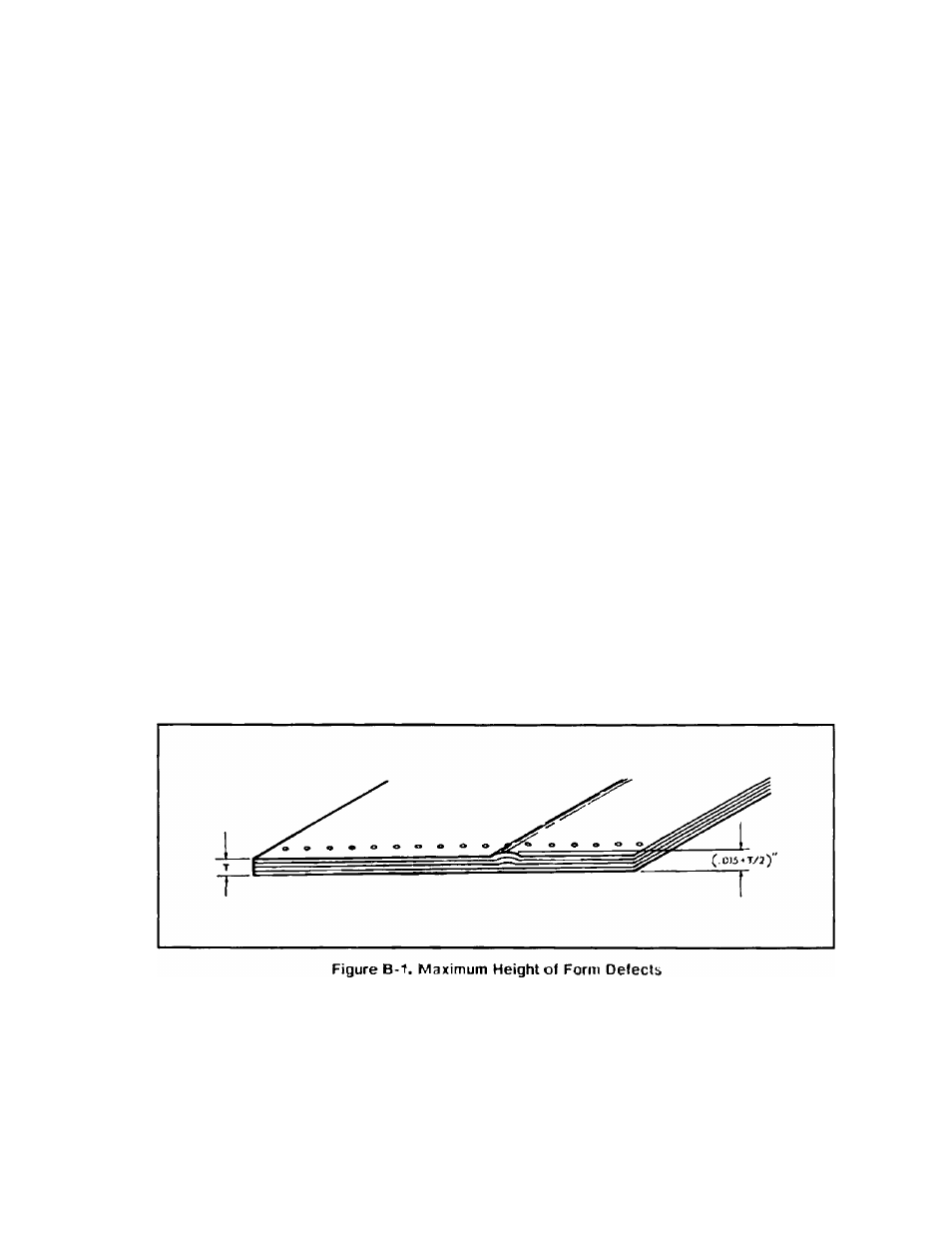

Case 1: Form Defect

In order to avoid hammer dragging, the overall thickness of a form plus

any defects should be no more than as shown in Figure B-1 (.015-t-T/2;

T=thickness) inch.

PAPER SPECIFICATIONS B-3