Remove and install oil pan seal, Remove and install crankcase oil seal – John Deere stx38 User Manual

Page 81

4/23/97

3 - 49

ENGINE

REPAIR

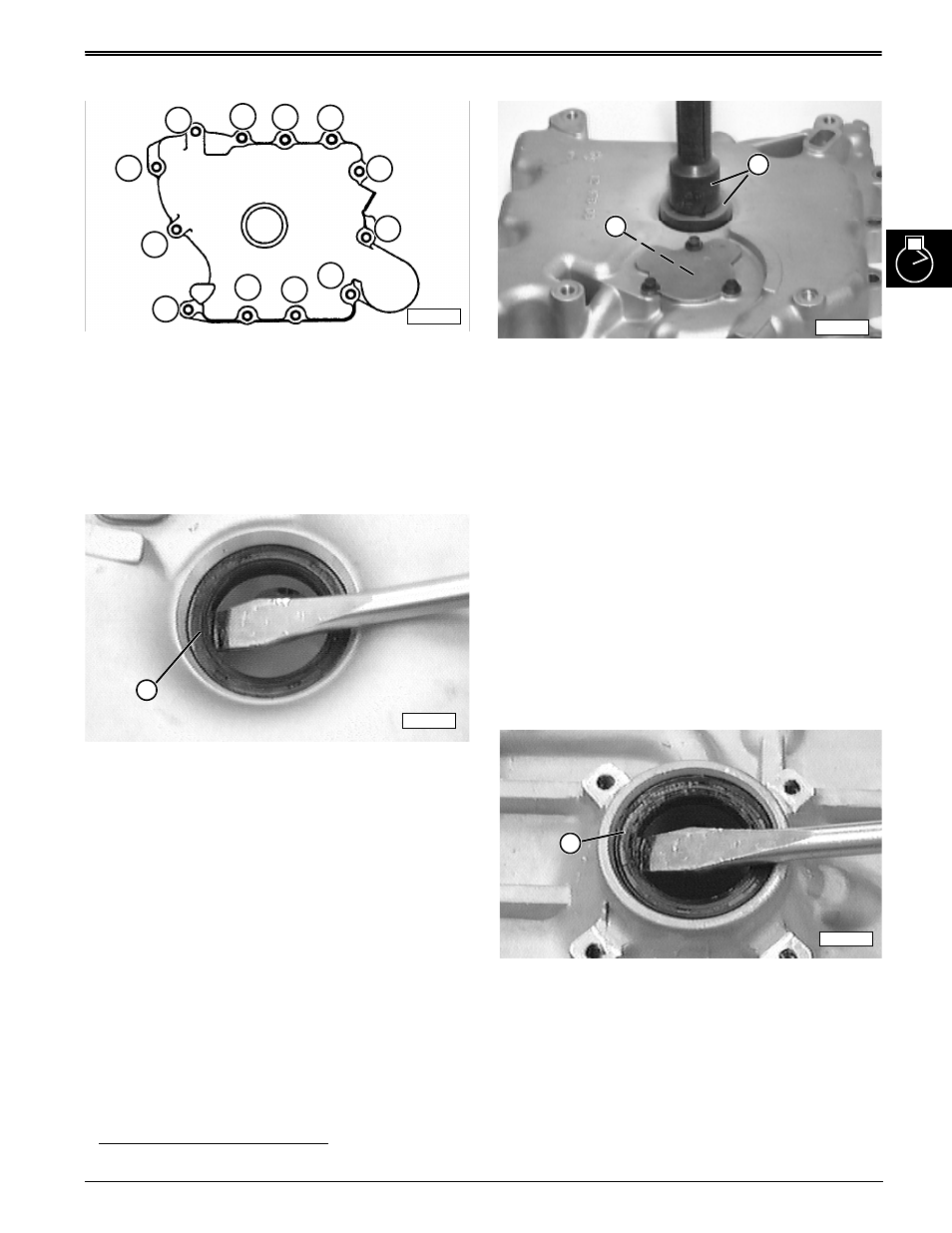

8. Install oil pan onto crankcase.

9. In sequence shown, tighten oil pan cap screws to

specification.

Specification:

Oil Pan Cap Screws . . . . . . . . . . 24 N•m (216 lb-in.) .

REMOVE AND INSTALL OIL PAN

SEAL

IMPORTANT: DO NOT damage pan bore when

removing seal.

1. Remove and discard seal (A).

2. When replacing crankshaft seals, apply a thin film

of LOCTITE®

1

598 or equivalent to the OD. of seal

1. Loctite is a product of the Loctite Corporation.

3. Using a suitable driver and disc (B), install new oil

seal to specification.

Specification:

Oil Pan Seal Depth

. . . . . . . . . . . . . . . . 2.49—2.98 mm (0.098—0.117 in.)

or until its top surface is flush with machined bore

opening.

4. Apply grease to inside lip of seal to aid installation.

IMPORTANT: Be sure to align flats (C) of balancer

shaft and oil pump inner rotor when installing

oil pan.

5. Prepare and install oil pan, see Remove And Install

Oil Pan.

REMOVE AND INSTALL

CRANKCASE OIL SEAL

IMPORTANT: DO NOT damage crankcase bore

when removing seal.

1. Remove and discard crankcase oil seal (A).

2. When replacing crankshaft seals, apply a thin film

of LOCTITE® 598 or equivalent to the OD. of seal.

3. Using a suitable driver and disc, install new oil seal

to specification.

M52076

5

3

1

12

10

8

6

4

2

11

9

7

M55903

A

M55946

B

C

M55902

A