Measure camshaft end play, Hydraulic valve lifters— remove and install, Hydraulic valve lifters— inspection – John Deere stx38 User Manual

Page 70

3 - 38

4/23/97

REPAIR

ENGINE

MEASURE CAMSHAFT END PLAY

1. Check that camshaft is seated in crankcase bore.

2. Measure play (A) between camshaft and straight

edge (spanning crankcase) using flat feeler gauge.

3. Use shims from Shim Kit as necessary until end

play is within specification.

Camshaft End Play Specification (with shims):

(Maximum) . . . . 0.076—0.127 mm(0.003—0.005 in.)

Shim Thickness Range:

The most commonly used shims are listed below.

Additional shims are available through the parts

catalogue.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.73 mm (0.29 in.)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.75 mm (0.30 in.)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.81 mm (0.32 in.)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.86 mm (0.34 in.)

HYDRAULIC VALVE LIFTERS—

REMOVE AND INSTALL

1. Remove camshaft.

IMPORTANT: Used lifters are mated to their

camshaft lobes. Mark them for installation in the

correct bore.

2. Remove lifters (A).

3. Inspect lifters for wear, replace as necessary.

4. Coat lifters with engine oil and install in correct

bore.

5. Install camshaft.

HYDRAULIC VALVE LIFTERS—

INSPECTION

Reasons:

• If lifter noise continues after 20 minutes of running,

it is probably an indication of contamination or dirt

in the lifter preventing the check ball from seating.

Replace lifter.

• A lifter which suddenly gets noisy while engine is

running would probably be caused by trapped. If

noise is caused by contamination, replace lifter. If

noise is caused by trapped air, see Step 2 under

“Lifter Noise After Start-Up”.

• Lifter noise which appears or worsens as the

engine heats up is usually due to wear in the lifters

and other engine components, especially if engine

has considerable running hours or has not had

regular oil changes. Replaces lifters and other

internal engine components that do not meet wear

limit specifications.

• A situation where the lifter seems to pump up too

much, holds a valve open, causes loss of

compression or hard starting, indicates insufficient

clearance between the plunger and body. Replace

lifter.

IMPORTANT: Damaged or worn lifters usually

indicate a damaged camshaft. Check camshaft

before replacing lifters.

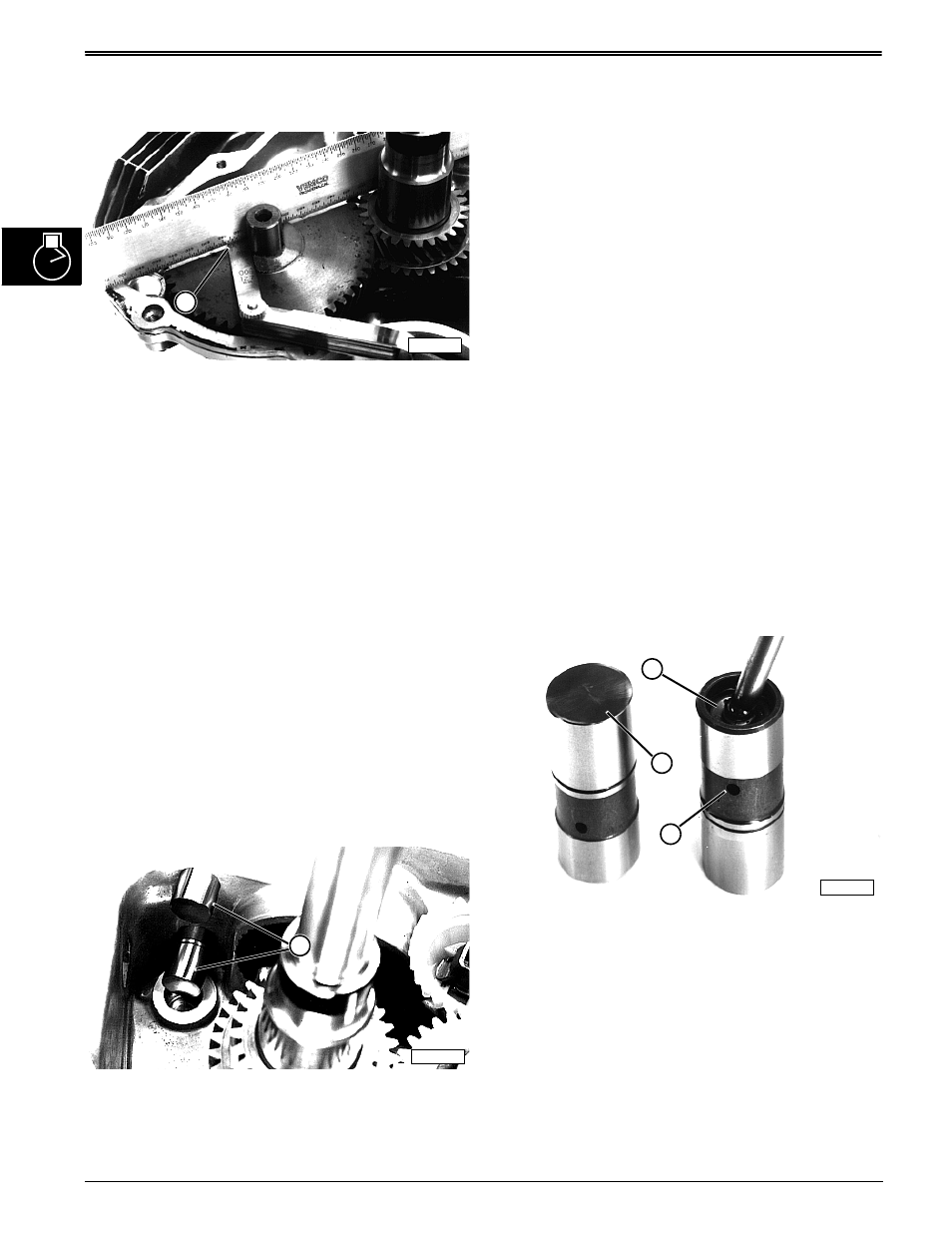

1. Inspect lifter face (B) for wear. Face should be flat

and smooth.

2. Use push rod to depress plunger (A). Plunger

should offer resistance but move smoothly.

3. Check that oil hole (C) is clear to inner piston.

4. Measure outside diameter of lifter.

M52093

A

M52094

A

M52095

B

A

C