Piston assembly, Install piston assembly – John Deere stx38 User Manual

Page 78

3 - 46

4/23/97

REPAIR

ENGINE

PISTON ASSEMBLY

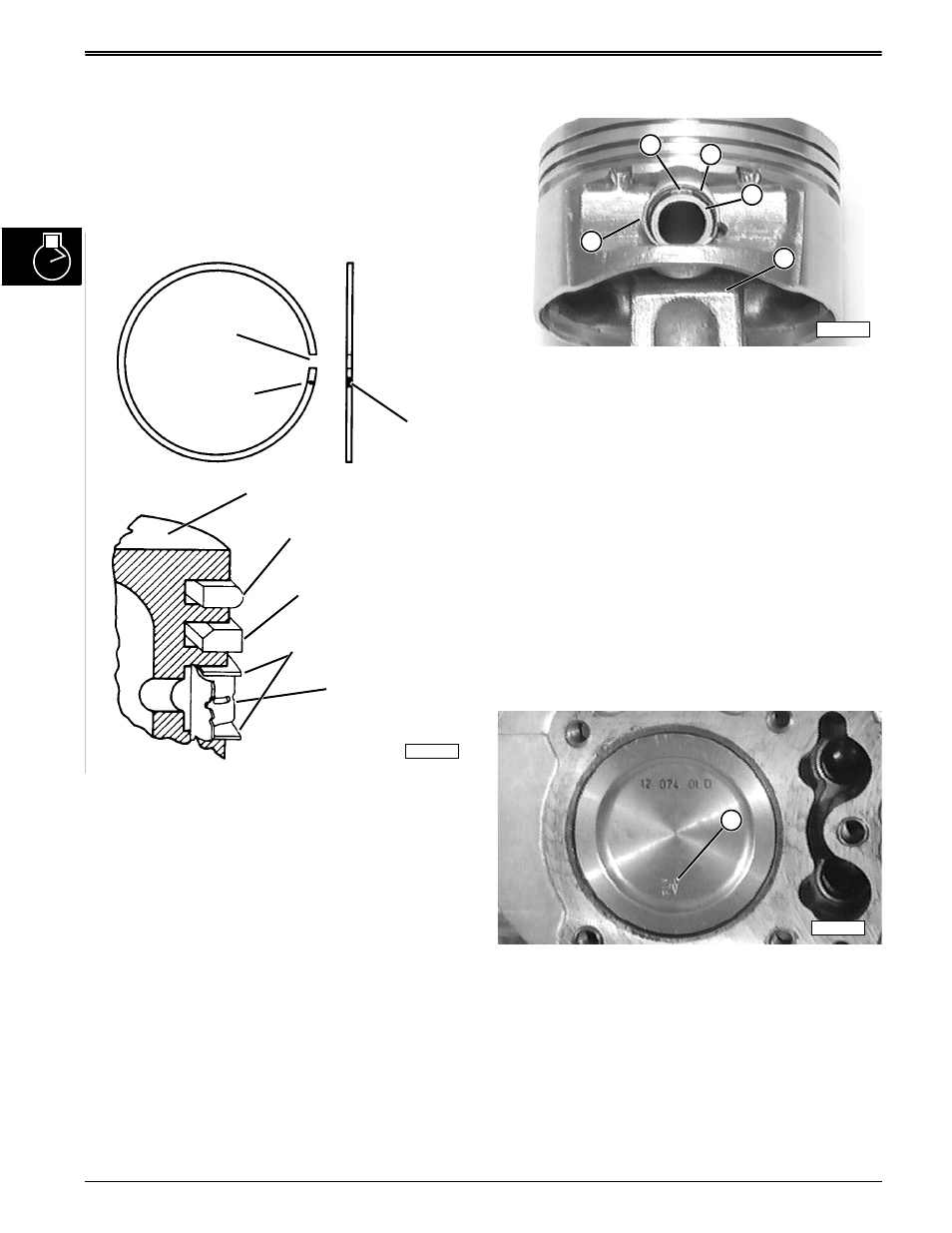

IMPORTANT: Side of ring marked TOP faces top of

piston with Dykem stripe to left of end gap. Top

compression ring has a blue Dykem stripe.

Bottom compression ring has a pink Dykem

stripe.

1. Install rings as shown on piston using ring

expander.

• Compression ring gaps should be staggered 120°.

• Note shape of compression rings and install as

shown.

• Compression rings should be installed with “Pip”

mark up and Dykem strip to left of ring gap.

• Install oil ring spacer first. Make sure that its ends

do not overlap.

• Stagger end gasp of oil rails 180° apart.

• Rings should turn freely in grooves.

NOTE: Install piston pin before retaining ring to

prevent possible scoring of bore.

IMPORTANT: Retaining rings (B) should be

installed with end gap (A) pointing up.

2. Install one piston pin retaining ring (B) in groove of

piston bore (E).

3. Install pin (C) through piston bore (E) and

connecting rod (D). Pin should install easily with

thumb pressure.

4. Install remaining retaining ring (B) in opposite side.

INSTALL PISTON ASSEMBLY

1. Install piston rings so piston ring end gaps are

staggered 120° apart.

2. Compress rings with ring compressor tool.

3. Coat cylinder, piston skirt, rod, and cap bearing

surfaces with oil.

4. Install piston with FLY mark (A) toward flywheel

side of crankcase. Use wooden dowel to push

piston into bore.

Oil Spacer

Oil Rails

Center Compression

Ring

Top Compression Ring

Piston

Ring Gap

“Pip” Mark

Dykem

Stripe

M55898

M5879

B

D

A

C

E

A

M55871