John Deere stx38 User Manual

Page 272

6 - 40

3/21/97

REPAIR

HYDROSTATIC POWER TRAIN

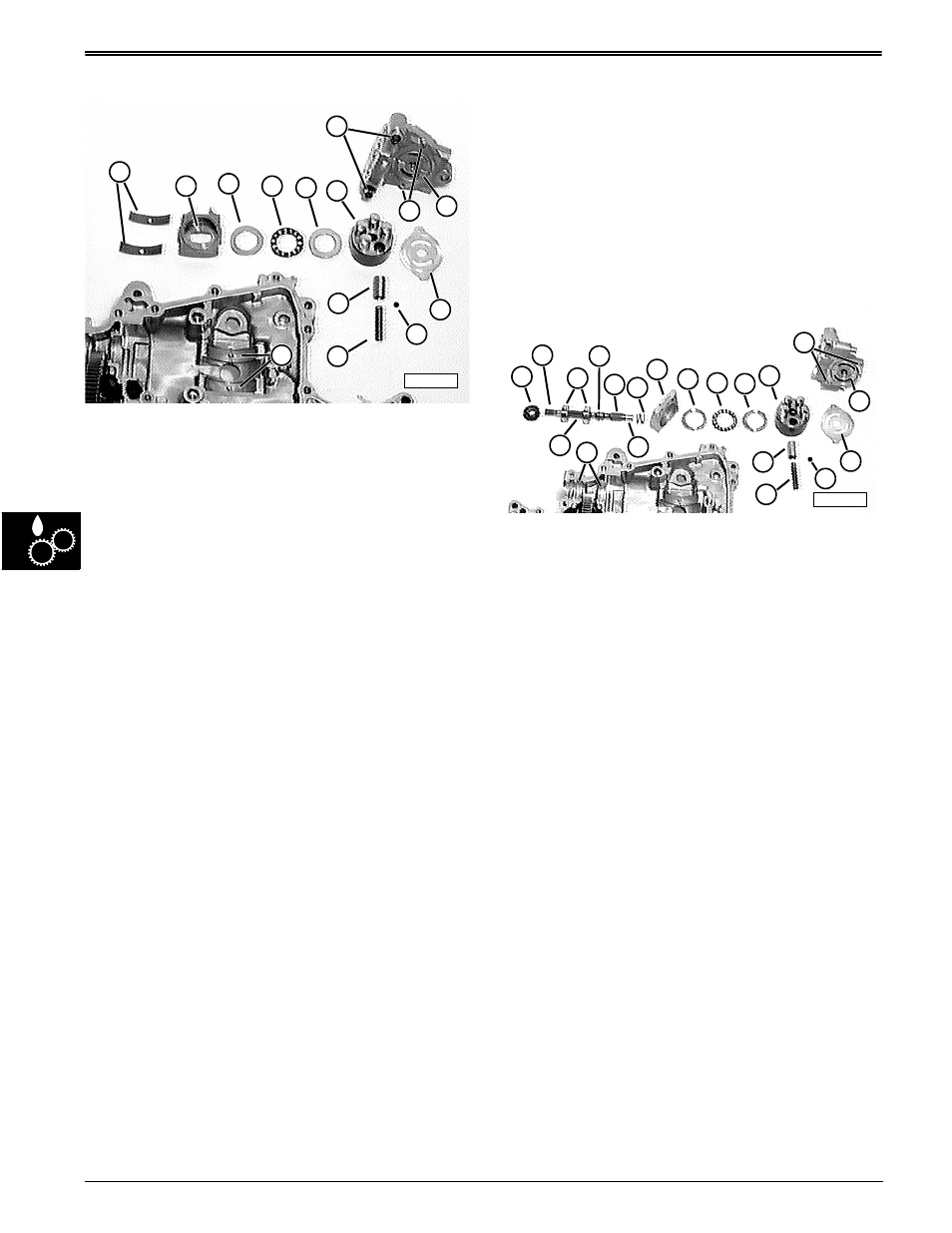

Disassemble and Inspect Pump and Swashplate—

IMPORTANT: PAY CLOSE ATTENTION to the

ORDER and ORIENTATION of ALL

COMPONENTS to their neighboring

components. Mark them, if necessary. This will

help greatly during assembly.

1. Carefully separate pump and swashplate

components.

2. Clean and inspect components individually once

disassembled:

• thrust bushings (A) should not be scored, pitted, or

worn badly—measure thickness:

Thrust bushings thickness

Minimum . . . . . . . . . . . . . . . . . . . 1.3 mm (0.05 in.)

• swashplate (B) machine surfaces of ramps and

bearing recess and bushing should not scored,

pitted, discolored, or worn badly

• swashplate roller bearing (C, D, and E) should not

be scored, pitted, discolored, missing any rollers,

or roller retainer broken

• pump cylinder block (F), pistons (L), washers (K),

and springs (M) must have free movement and

should not be scored, pitted, discolored, distorted,

or worn

• bronze pump plate (J) and mating surface of

cylinder block (F) should not be grooved,

discolored, or worn thin around ports;

• center block machined surface (I) should not

scored, pitted, or discolored

• center block rolled pins (G) and dowel pins (H)

should be in good condition, not missing or

sheared off

• upper case ramps and centering pins (N) should be

in good condition.

IMPORTANT: If thrust bushings and swashplate

ramps are damaged, they must be replaced as a

set. If swashplate recess machined surface or

bushing are damaged, replace with new

swashplate (bushing is not serviced separately).

If bronze pump plate or center block are

damaged, they both must be replaced. If any

component of pump cylinder block is damaged,

a complete new pump cylinder block must be

ordered.

Disassemble and Inspect Motor and Drive Shaft—

IMPORTANT: PAY CLOSE ATTENTION to the

ORDER and ORIENTATION of ALL

COMPONENTS to their neighboring

components. Mark them, if necessary. This will

help greatly during assembly.

1. Carefully separate motor and drive shaft

components.

2. Clean and inspect components individually once

disassembled.

• drive shaft seal must be replaced every time drive

shaft is removed or case halves separated

• drive shaft splines (B and E) should be in good

condition, not chipped, broken, or worn

• drive shaft ball bearings (C) should not be scored,

pitted, loose, or discolored;

• drive shaft snap ring (D) should be in good

condition as should its groove

• drive shaft machined surface (R) should not be

scored, pitted, or worn

• drive shaft spur gears (T) should have 6 teeth, not

be scored, pitted, discolored, chipped or broken,

nor worn thin

• drive shaft-to-cylinder block spring (F) should be in

good condition, not weak, broken, nor distorted

M58217

A

B

D

E

J

C

L

K

N

F

M

I

G

H

M58218

A

B

C

D

E

T

F

G

H

I

J

K

M

N

S

R

O

Q

P

L