John Deere stx38 User Manual

Page 48

3 - 16

4/23/97

DIAGNOSIS

ENGINE

ENGINE HARD TO START AND/OR

ENGINE STARTER KICKS OUT

NOTE: Use correct starting procedure as listed in

operator’s manual. The procedure of cranking

the engine for 5 seconds and waiting for 10

seconds will improve starting and decrease

total cranking time. The 10 second pause

allows fuel in the manifold time to evaporate for

improved combustion, reducing the chance of

flooding and muffler backfire.

Test Conditions:

• Control lever in full choke position.

• Crank engine for 5 seconds. If engine does not

start, pause for 10 seconds, then crank for 5 more

seconds. Continue this 5 seconds on, 10 seconds

off cycle until engine starts. If starter kicks out see

step 8. When engine tries to start, continue

cranking beyond the 5 seconds of that cycle until it

starts.

• As engine warms up, move choke control back

gradually. This will help to lessen excessive

exhaust smoke, engine “loading up”, or backfire.

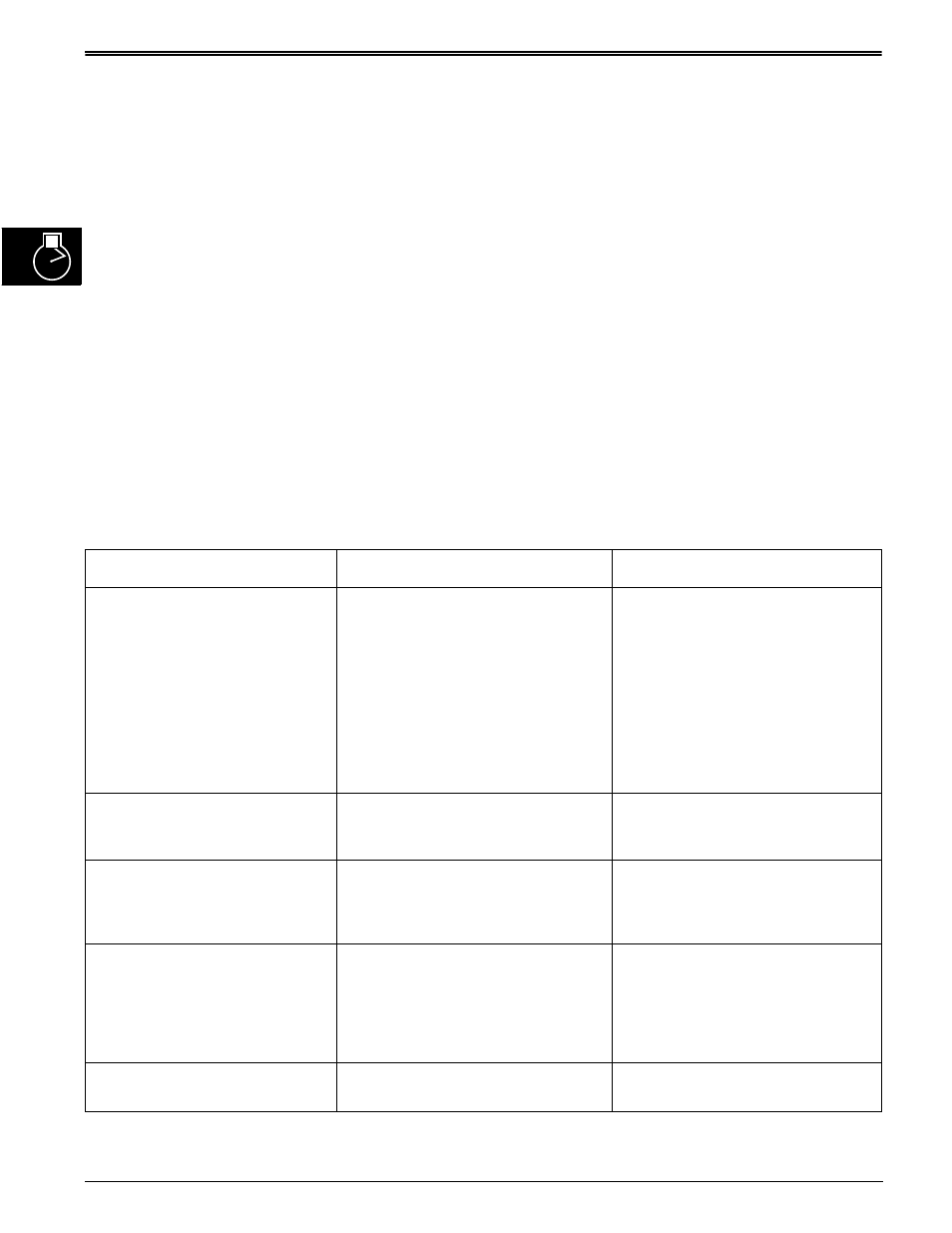

Test/Check Point

Normal

If Not Normal

1. Cranking speed.

At least 300 RPM.

If cranking speed is below 300 RPM

check the following:

Low battery output—Load test

battery for correct amperage output.

Engine oil weight too heavy.—Only

multi-viscosity oil is recommended.

Battery or starter terminals

corroded.

Starter failure.

Automatic compression release

(ACR) is not working correctly.

2. Choke adjustment.

Choke plate must be completely

closed when throttle lever is in full

choke position.

Adjust throttle cable, choke,

governor, and idle speeds.

3. Spark plug.

Use in line spark tester

(D-05351ST)

Clean, undamaged, and gapped

correctly 1.0 mm (0.04 in.). Spark

plug should provide a strong blue

spark.

Repair or replace.

4. Carburetor

Must have adequate supply of fresh,

clean fuel.

Perform fuel flow test.

Connect a remote, gravity feed tank

with fresh fuel after performing fuel

flow test. This procedure will identify

stale fuel problem.

Clean carburetor.

5. Air cleaner.

Clean and undamaged.

Clean or replace foam pre-cleaner

and air filter element as needed.