Ignition module test, Seat switch test – John Deere stx38 User Manual

Page 152

4 - 68

3/21/97

TESTS AND ADJUSTMENTS

ELECTRICAL

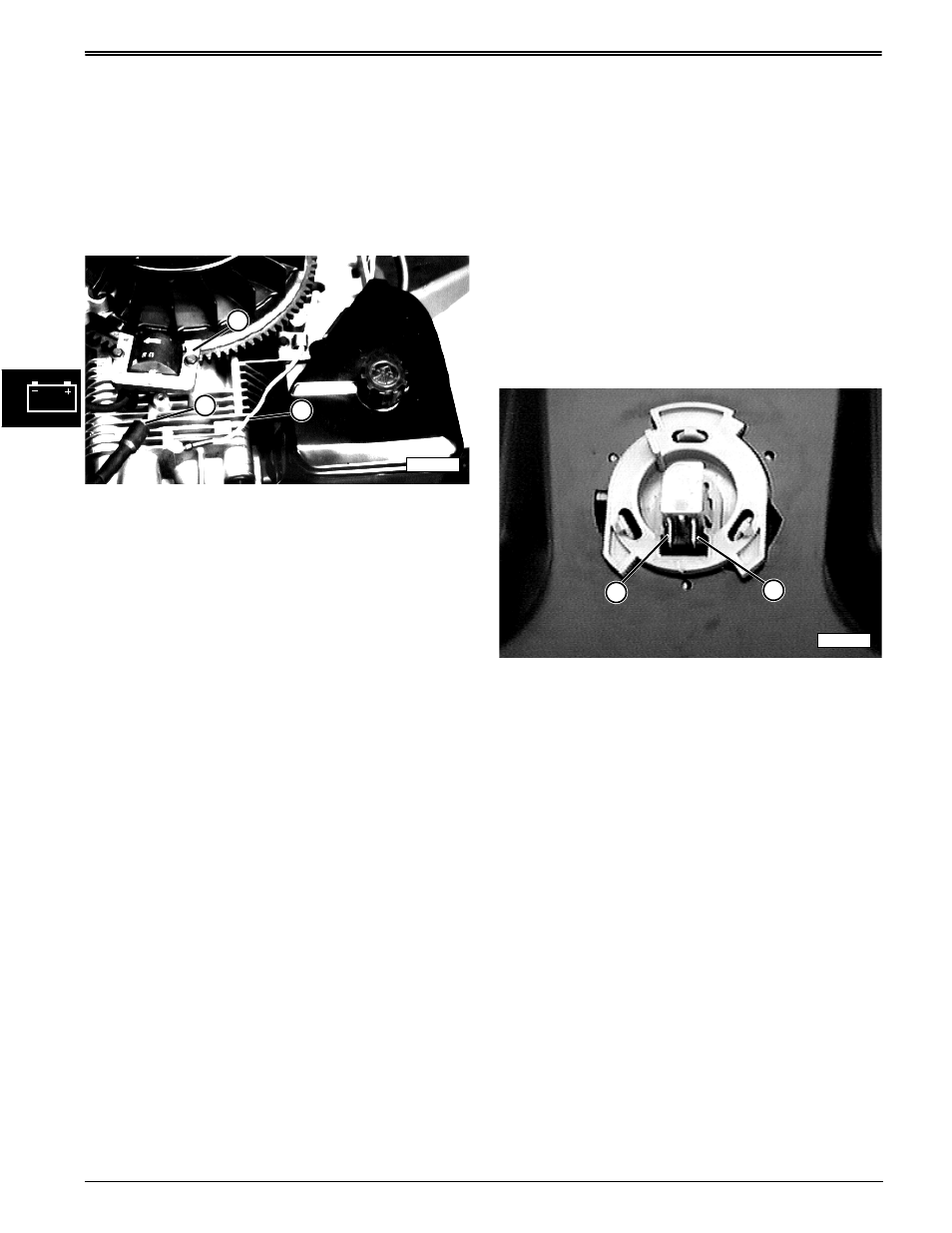

IGNITION MODULE TEST

Reason:

To determine condition of ignition module windings.

Equipment:

• Ohmmeter

Procedure:

1. Put transaxle in neutral. Put key switch in off

position.

2. Remove spark plug cap from spark plug wire.

3. Disconnect primary lead wire.

4. Measure resistance between primary lead (B) and

core (A). Reverse meter leads and check

resistance again.

5. Measure resistance between spark plug lead (C)

and core (A).

Specifications:

Primary lead and core resistance:

One direction . . . . . . . . . . . . . . . . . . . 5—1000 ohms

Other direction (Minimum) . . . . . . . . . . . 30 K ohms

Spark plug lead and core

resistance . . . . . . . . . . . . . . . . .7.9—10.85 K ohms

Results:

• If resistance does not meet specifications, replace

the ignition module.

SEAT SWITCH TEST

Reason:

To ensure proper operation of seat switch.

Equipment:

• Ohmmeter

Procedure:

1. Park machine on level surface and turn key switch

OFF.

2. Shift lever in NEUTRAL and park brake LOCKED.

3. Disconnect harness connector from seat switch.

4. Check continuity across switch terminals (A) and (B).

Results:

• There should BE continuity between terminals (A

and B) when seat is RELEASED,

• There should NOT BE continuity between terminals

(A and B) when plunger is DEPRESSED.

• If continuity is NOT correct, replace switch.

NOTE: The seat switch connector has an interlock

spring which shorts the 3 wires together when

it is removed from the seat switch terminals.

Check that spring mechanism is releasing

properly when the center tab is depressed.

M55638

B

A

C

B

A

M55816